Pneumatic Valve Seal Assembly 20428052 Pump Replacement Parts

Pneumatic Valve Seal Assembly 20428052 Pump Replacement Parts

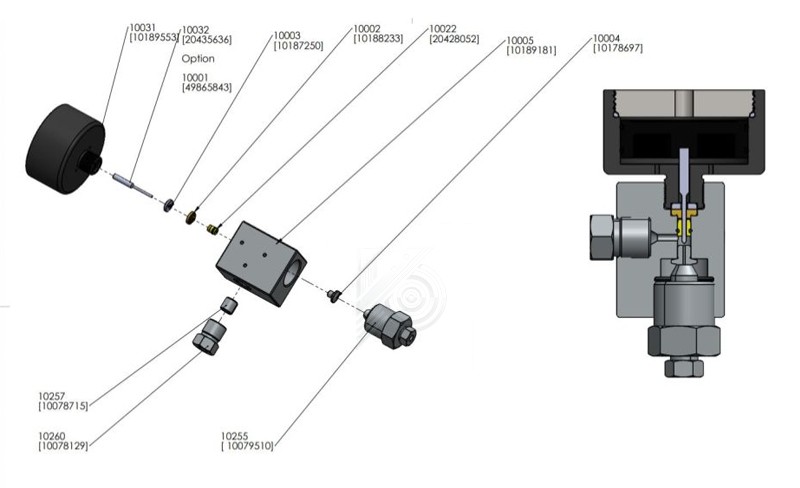

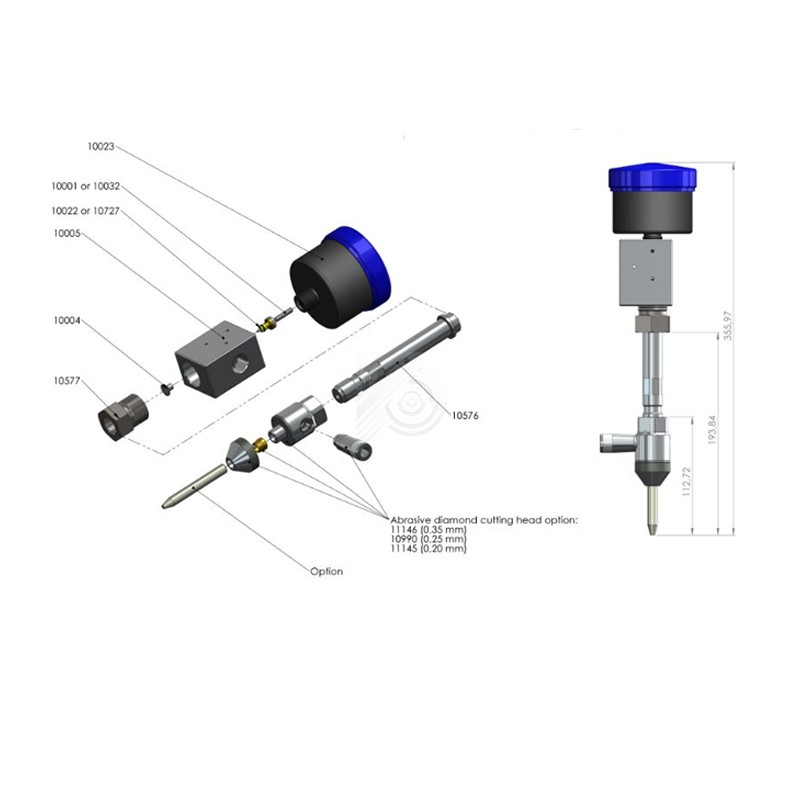

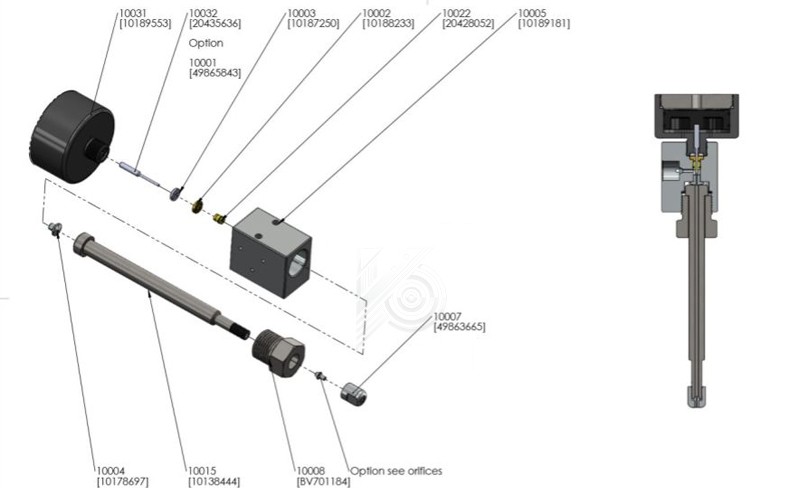

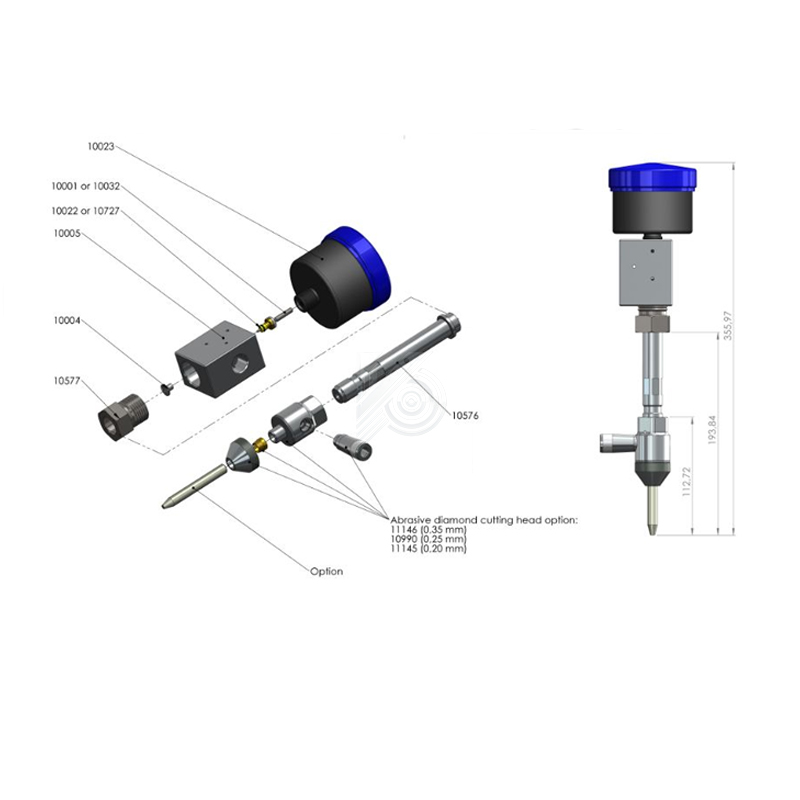

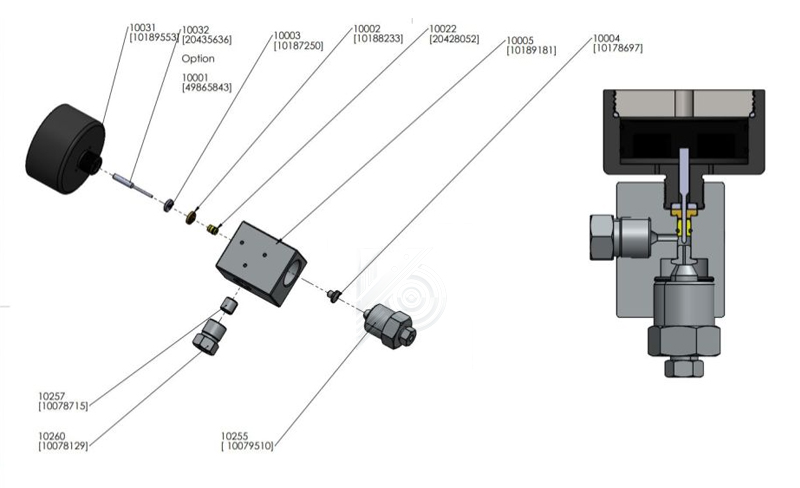

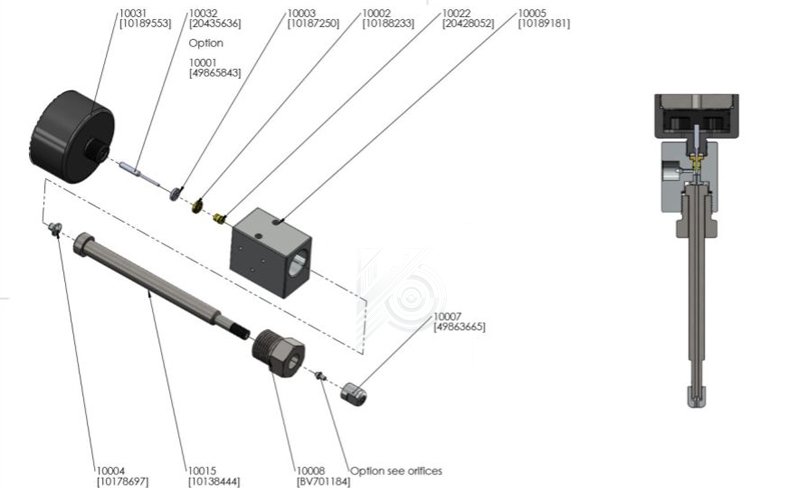

The part 20428052 is a seal assembly for the HP pneumatic on/off (dump) valve used in 60 000 psi (4 100 bar) Waterjet Intensifier Pumps. This precision seal kit maintains airtight performance in normally-open pneumatic valve actuators, preventing hydraulic and air leaks that can compromise cycle control and machine safety.

Specifications

Valve Type:Normally-open pneumatic dump (on/off) valve seal assembly

Rated Pressure:60 000 psi (4 100 bar)

Operating Medium:Clean, dry compressed air (typically 80–100 psi supply)

Component Materials:O-rings, PTFE backup rings, stainless steel bearing disk

Seal Cross-Section:0.25″ (6.35 mm) ID/OD format (0.25″ nominal diameter)

OEM SKU:20428052

Installation & Maintenance

Shutdown & Depressurize: Isolate hydraulic and pneumatic supplies; relieve system pressure.

Remove Valve Assembly: Unscrew the pneumatic valve from the intensifier manifold and disconnect solenoid wiring if present.

Disassemble Valve: Extract the old seal assembly—O-rings, backup rings, and bearing disk—using suitable picks or presses.

Inspect & Clean: Degrease all mating surfaces and inspect the actuator bore for scoring or damage.

Install New Seal Kit: Lubricate new O-rings with manufacturer-approved lubricant; seat backup rings and bearing disk in correct orientation.

Reassemble & Test: Reinstall the valve, reconnect air and electrical, bring up to low air pressure for leak check, then ramp hydraulic pressure to verify proper dump action and sealing.

Specifications

Valve Type:Normally-open pneumatic dump (on/off) valve seal assembly

Rated Pressure:60 000 psi (4 100 bar)

Operating Medium:Clean, dry compressed air (typically 80–100 psi supply)

Component Materials:O-rings, PTFE backup rings, stainless steel bearing disk

Seal Cross-Section:0.25″ (6.35 mm) ID/OD format (0.25″ nominal diameter)

OEM SKU:20428052

Installation & Maintenance

Shutdown & Depressurize: Isolate hydraulic and pneumatic supplies; relieve system pressure.

Remove Valve Assembly: Unscrew the pneumatic valve from the intensifier manifold and disconnect solenoid wiring if present.

Disassemble Valve: Extract the old seal assembly—O-rings, backup rings, and bearing disk—using suitable picks or presses.

Inspect & Clean: Degrease all mating surfaces and inspect the actuator bore for scoring or damage.

Install New Seal Kit: Lubricate new O-rings with manufacturer-approved lubricant; seat backup rings and bearing disk in correct orientation.

Reassemble & Test: Reinstall the valve, reconnect air and electrical, bring up to low air pressure for leak check, then ramp hydraulic pressure to verify proper dump action and sealing.