Dump Valve Assembly 20427739 Waterjet Pump Replacement Parts

Dump Valve Assembly 20427739 Waterjet-Pump-5-Axis-Waterjet-Cutting-Machine-For-Carbon-Fiber-p.html target='_blank'>Waterjet Pump Replacement Parts

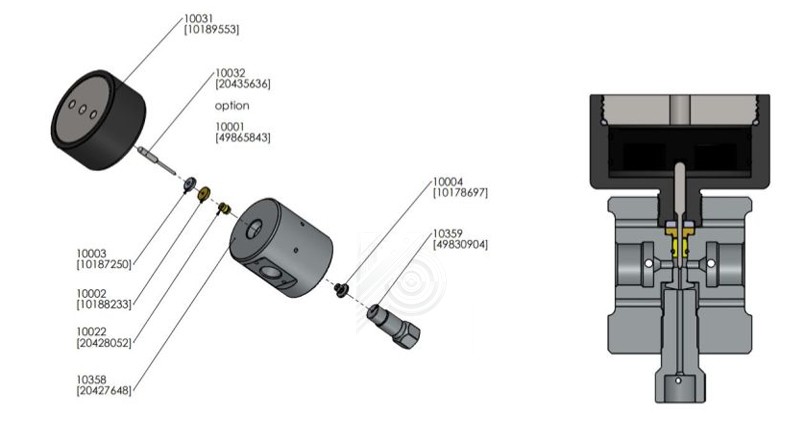

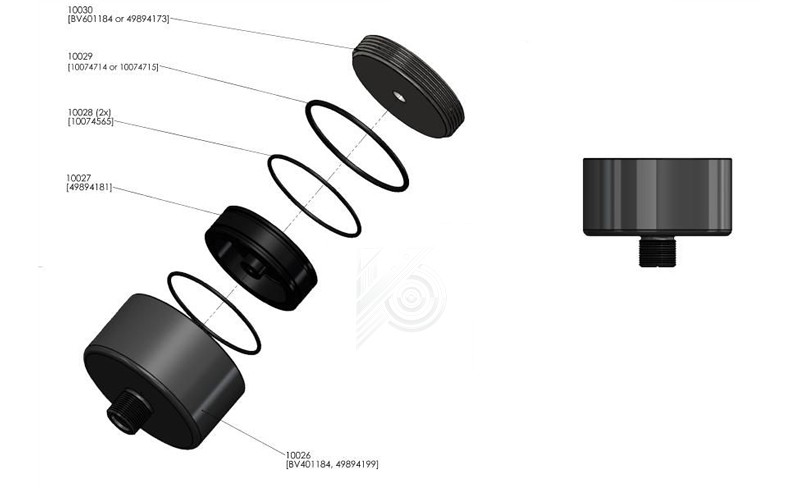

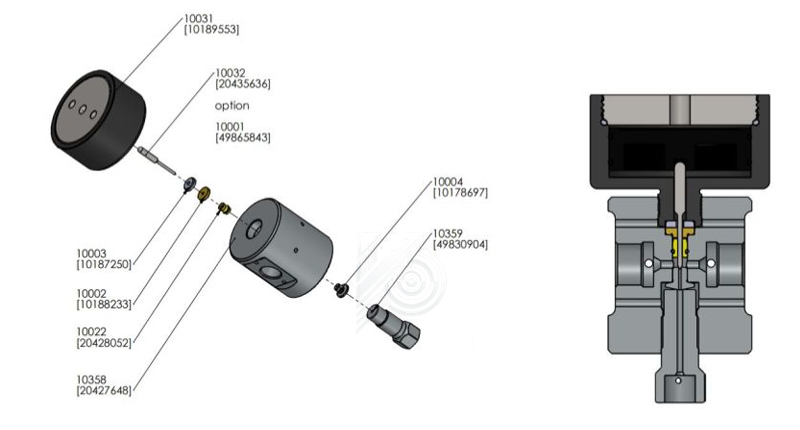

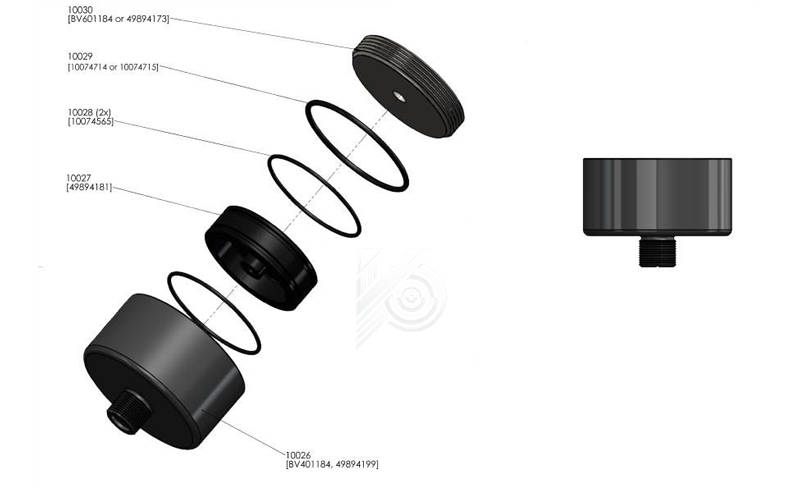

The part 20427739 is a normally-open pneumatic dump valve assembly (“round, 3-port dump valve”) designed for 60 000 psi (4 100 bar) waterjet Intensifier Pumps. It serves as the critical pressure-dump control for safe shutdown and cycle control.

Specifications

Valve Type:Normally-Open pneumatic dump valve, round 3-port

Rated Pressure:60 000 psi / 4 100 bar

Air Supply:75–125 PSIG via 1/8″-27 NPT RH inlet

High-Pressure Ports:Two × 3/8″ HP connections

Body Material:Stainless steel

Actuator Bore:1/8″ internal pneumatic actuator

Dimensions (approx.):Round body ~100 mm diameter; overall length:~120 mm (see service manual)

Port Threads:¾″-16 UNF LH high-pressure ports; 1/8″-27 NPT RH air inlet

Installation & Maintenance

System Shutdown & Depressurization: Turn off the pump, isolate hydraulic supply, and relieve system pressure.

Air Isolation: Shut off compressed-air feed to the actuator.

Valve Removal: Unscrew the dump valve assembly from the intensifier manifold and disconnect solenoid wiring if present.

Inspection: Check O-rings, seals, and actuator piston for wear; replace with OEM repair kit 5116017 if needed

Reinstallation: Thread valve into manifold, reconnect air supply, and solenoid wiring.

Functional Test: Apply low air pressure (75 PSIG), cycle valve to verify dump action, then ramp to full operating pressure while monitoring for leaks.

Specifications

Valve Type:Normally-Open pneumatic dump valve, round 3-port

Rated Pressure:60 000 psi / 4 100 bar

Air Supply:75–125 PSIG via 1/8″-27 NPT RH inlet

High-Pressure Ports:Two × 3/8″ HP connections

Body Material:Stainless steel

Actuator Bore:1/8″ internal pneumatic actuator

Dimensions (approx.):Round body ~100 mm diameter; overall length:~120 mm (see service manual)

Port Threads:¾″-16 UNF LH high-pressure ports; 1/8″-27 NPT RH air inlet

Installation & Maintenance

System Shutdown & Depressurization: Turn off the pump, isolate hydraulic supply, and relieve system pressure.

Air Isolation: Shut off compressed-air feed to the actuator.

Valve Removal: Unscrew the dump valve assembly from the intensifier manifold and disconnect solenoid wiring if present.

Inspection: Check O-rings, seals, and actuator piston for wear; replace with OEM repair kit 5116017 if needed

Reinstallation: Thread valve into manifold, reconnect air supply, and solenoid wiring.

Functional Test: Apply low air pressure (75 PSIG), cycle valve to verify dump action, then ramp to full operating pressure while monitoring for leaks.