News

What is the function of AC5-axis waterjet cutting head?

What is the function of AC5-axis Waterjet Cutting Head?

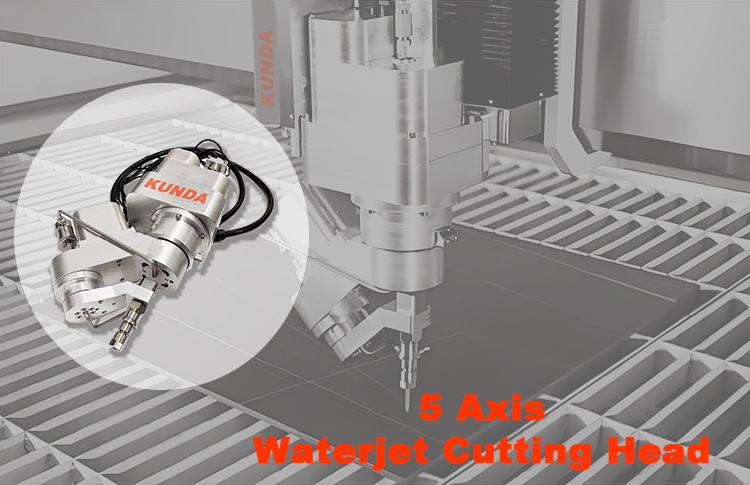

The 5 Axis Cutting Head is a high-Precision Waterjet Cutting Head that adds two rotating axes, A and C, to the traditional three-axis (X, Y, Z) waterjet cutting. Waterjet cutting (also known as water jet) uses high-speed, high-pressure water flow to carry abrasives to cut workpieces. In the AC five-axis head, the A axis usually rotates around a horizontal axis parallel to the workpiece surface to change the nozzle tilt angle; the C axis rotates around an axis perpendicular to the workpiece surface to achieve continuous rotation and positioning of the nozzle. This design allows the cutting head to adjust the jet direction at any angle in three-dimensional space, thereby achieving plane processing and complex three-dimensional modeling processing at one time. For example, the Weihong AC five-axis waterjet cutting head has a strong structural rigidity and small thermal deformation. It can be integrated into a standard three-axis machine tool platform to achieve plane and three-dimensional integrated processing; its C axis supports unlimited rotation and high-speed cornering, and can continuously cut without pausing. In addition, the five-axis Cheapest WaterJet Cutter linkage makes the cutting path more continuous and smooth, and no obvious dots will be produced at special-shaped corners, achieving high-quality cutting effects. In general, the AC five-axis waterjet cutting head relies on the basic principle of high-pressure water flow and abrasive composite jet, and expands the posture freedom of the cutting head through two-axis linkage, thereby realizing the cutting function in any direction.

Based on the three-axis motion, the 5 Axis Water Jet Head significantly improves the processing flexibility through the linkage of the A-axis and the C-axis. The modern AC five-axis water jet head is controlled by precision servo, and the fixed-point cutting accuracy can reach ±0.05 mm, which is higher than the traditional three-axis system. Five-axis linkage cutting eliminates the alignment errors caused by multiple clamping, can form complex parts in one go, and has better overall accuracy. However, since the five-axis head has more kinematic pairs, it needs to be calibrated regularly; the head itself is heavy and may also have a slight effect on dynamic accuracy. On the whole, the AC five-axis water jet head Cnc Water Jet achieves processing accuracy comparable to or even higher than that of the three-axis system through active control and optimized structure while ensuring high precision.

The A axis of the 5 Axis Waterjet Head can rotate around the X or Y axis, and the C axis can rotate around the Z axis. The linkage of the two axes can allow the nozzle to rotate in more directions to adapt to complex curved surfaces. As mentioned earlier, the five-axis head can be linked to cut in any direction, and there is no need to pause when cutting corners and there is no "turning point". The cutting path is continuous and smooth. Therefore, the 5-Axis Waterjet Cutting Heads can complete multi-directional bevel cutting, chamfering, and complex curved surface cutting tasks at one time, and its flexibility far exceeds that of three-axis and four-axis systems.

The Abrasive Waterjet Head can directly cut thick plates, complex surfaces or cylinders by taking advantage of its adjustable angle, which usually requires multiple flipping and clamping of three or four axes to complete.

The application is more extensive and high-end. It can perform integrated processing on complex three-dimensional parts, such as interior parts and engine parts (such as gears and impellers) in the automotive industry, and can form various inclined surfaces and curved surfaces at one time; when the aerospace field requires extremely high-precision three-dimensional parts made of titanium alloy or composite materials, the Cnc Abrasive WaterJet Cutting Machine is the best choice, which can process the hardest materials and ensure accuracy; the stone and decoration industries can complete processes such as cylindrical mosaics, large-angle chamfers and fine rounding; in addition, five-axis Water Jets are also commonly used in prototype manufacturing, mold processing, precision hardware manufacturing and other occasions that require three-dimensional continuous contours. It can be said that the emergence of AC five-axis heads has greatly expanded the application of water jets in the field of complex parts processing.