News

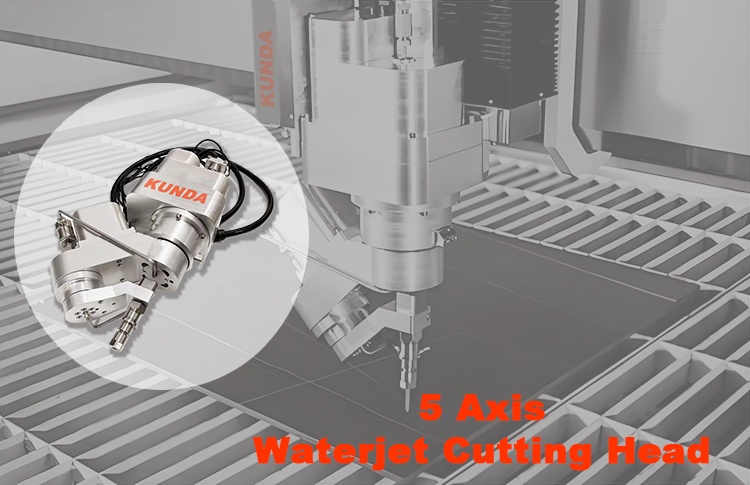

What are the advantages and disadvantages of a five-axis waterjet cutting head?

What are the advantages and disadvantages of a five-axis Waterjet Cutting Head?

Advantages: The Ac 5 Axis Cutting Head provides extremely high flexibility and processing capabilities through five-axis linkage, which can achieve cutting at any angle in three-dimensional space and forming complex parts in one go. Its structure is rigid and has good heat dissipation. The auxiliary software has high calculation and control precision, and the cutting accuracy can reach ±0.05 mm. At the same time, the C-axis has unlimited rotation and high-speed cornering to improve the efficiency of continuous cutting. Compared with traditional Water Jets, the 5 Axis Water Jet Cutting Services Near Me system reduces manual flipping and multiple processes, further improving production efficiency and reducing human errors. Therefore, in some high-end manufacturing industries and complex shape processing, the AC five-axis Water Jet Cnc Machine can form in one go, saving costs and improving product quality.

Disadvantages: Due to the addition of two rotating axes, the mechanical structure and control system of the Ac 5-axis Water Jet Head are more complex, and the equipment procurement and maintenance costs are greatly increased. Expensive five-axis machine tools may require higher capital investment and more professional operation training. The machine head itself is heavy and large in size, and has higher requirements for the rigidity of the CNC system and machine tools. In some cases, the cutting speed may be slightly lower than that of similar three-axis equipment (especially when running at high speed and high load). In addition, five-axis Marble WaterJet Cutting Machine processing requires more complex programming, and some geometrically extreme surfaces still have process limitations. In general, the AC 5-Axis Waterjet Head has significant advantages in high-precision and high-complexity processing, but the equipment cost is high, and the maintenance and usage thresholds are also correspondingly higher. It is suitable for processing scenarios with extremely high processing quality requirements or complex-shaped parts.

More details,please contact us!