Hp Pneumatic Dump Valve 3 Port Adaptor 49830904 Waterjet Pump Parts

Hp Pneumatic Dump Valve 3 Port Adaptor 49830904 Waterjet-Pump-5-Axis-Waterjet-Cutting-Machine-For-Carbon-Fiber-p.html target='_blank'>Waterjet Pump Parts

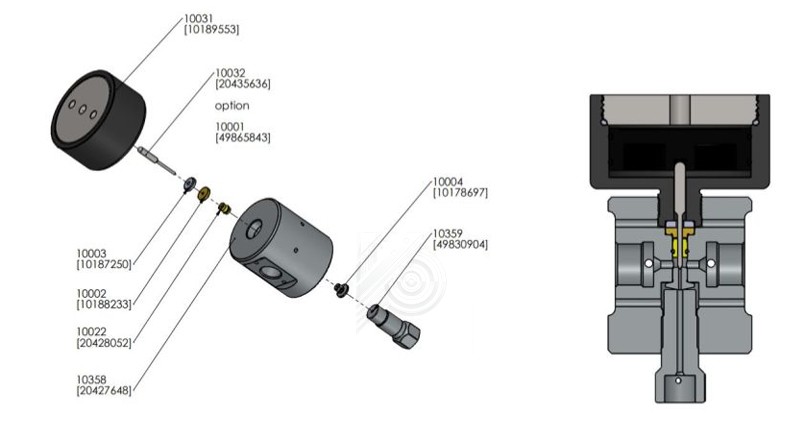

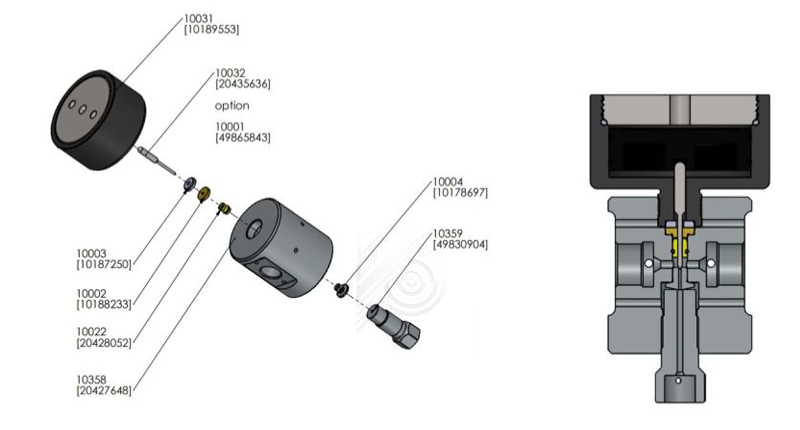

The part 49830904 is an OEM adapter for the normally-open, 3-port round dump valve used on 60 000 psi (4 100 bar) waterjet Intensifier Pumps. It provides the interface between the actuator and valve body, ensuring reliable rapid venting of hydraulic pressure for cycle control and emergency shutdown.

Specifications

Pressure Rating:60 000 psi (4 100 bar)

Valve Type:Normally-open, 3-port, round dump valve adaptor

Connections:Female ¼″ high-pressure inlet; mates with ¾″-16 UNF LH valve ports

Material:Stainless steel alloy

Weight & Dimensions:Approx. 0.2 lb; compact round body

Installation & Maintenance

System Shutdown: Turn off the waterjet pump and isolate both hydraulic and pneumatic supplies.

Valve Removal: Unscrew the pneumatic dump valve body from the intensifier manifold.

Extract Adapter: Remove the old 3-port adapter; inspect mating surfaces for wear or damage.

Install New Adapter: Thread part 49830904 into the valve body until hand-tight, then torque per specification (typically ~20 ft-lb).

Reassemble & Test: Reinstall the valve, reconnect air and hydraulic lines, cycle at low pressure to check leaks, then ramp to full 60 K psi and verify proper dump action.

Specifications

Pressure Rating:60 000 psi (4 100 bar)

Valve Type:Normally-open, 3-port, round dump valve adaptor

Connections:Female ¼″ high-pressure inlet; mates with ¾″-16 UNF LH valve ports

Material:Stainless steel alloy

Weight & Dimensions:Approx. 0.2 lb; compact round body

Installation & Maintenance

System Shutdown: Turn off the waterjet pump and isolate both hydraulic and pneumatic supplies.

Valve Removal: Unscrew the pneumatic dump valve body from the intensifier manifold.

Extract Adapter: Remove the old 3-port adapter; inspect mating surfaces for wear or damage.

Install New Adapter: Thread part 49830904 into the valve body until hand-tight, then torque per specification (typically ~20 ft-lb).

Reassemble & Test: Reinstall the valve, reconnect air and hydraulic lines, cycle at low pressure to check leaks, then ramp to full 60 K psi and verify proper dump action.