Flat End Pneumatic Valve Stem 20435636 Techni Water Jet Pump Parts For Sale

Flat End Pneumatic Valve Stem 20435636 Techni Waterjet-Cutter-Machine-Price-p.html target='_blank'>Water Jet Pump Parts For Sale

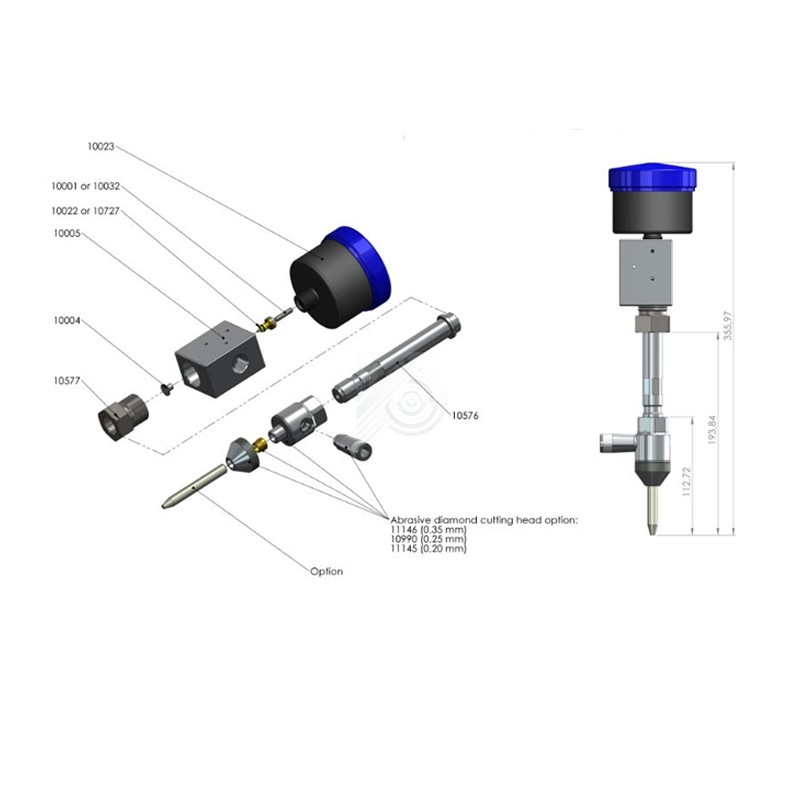

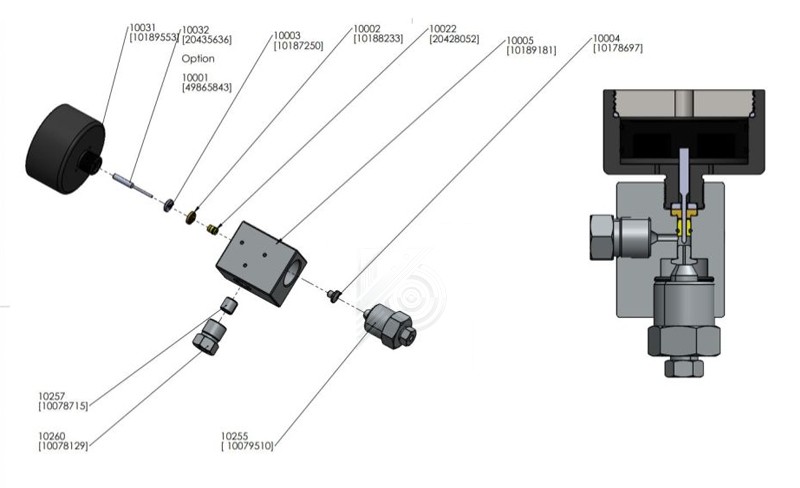

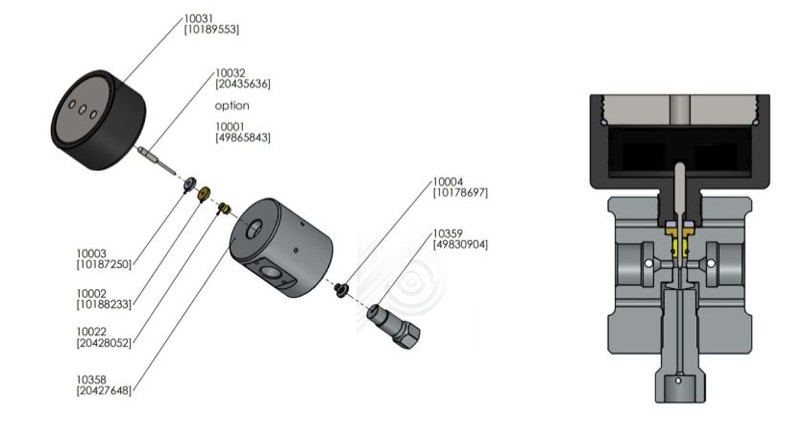

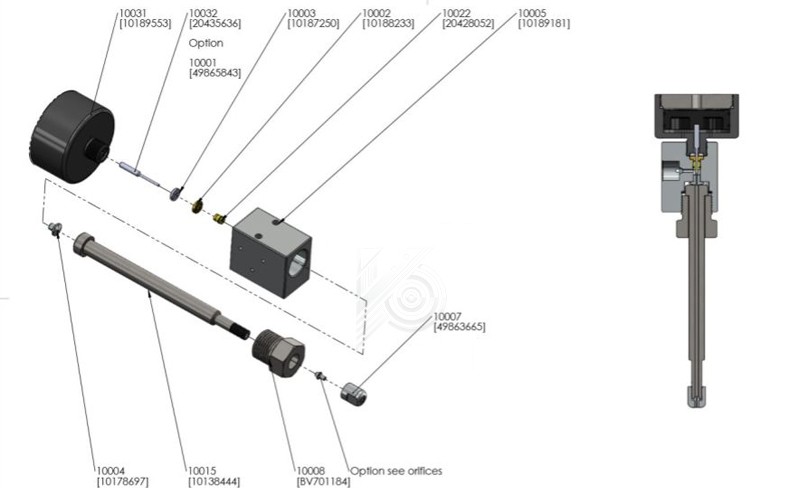

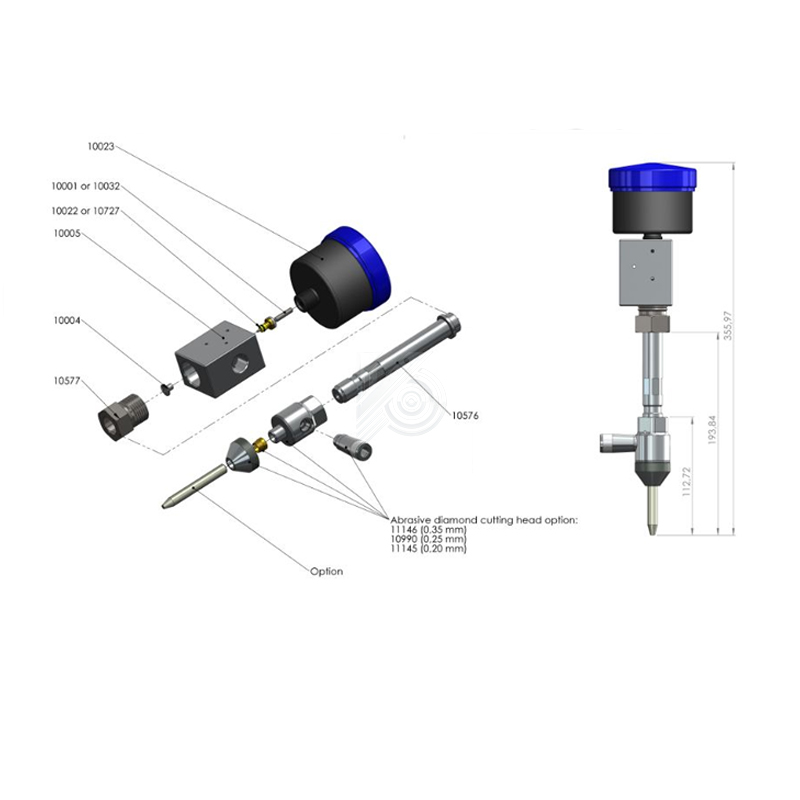

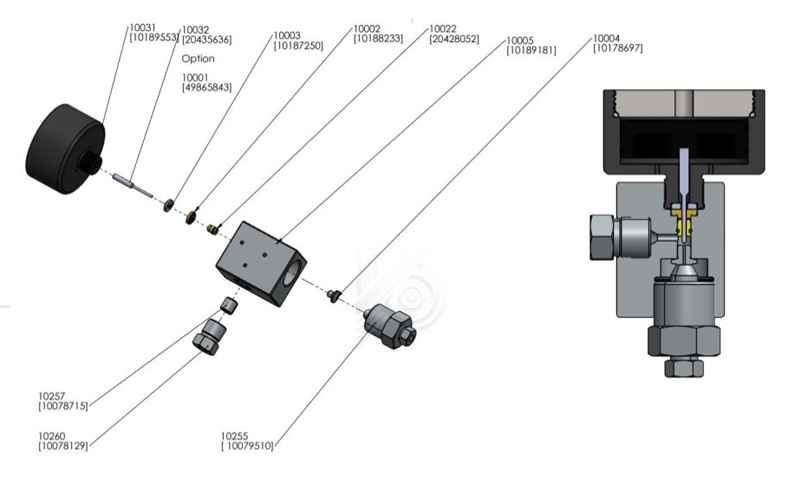

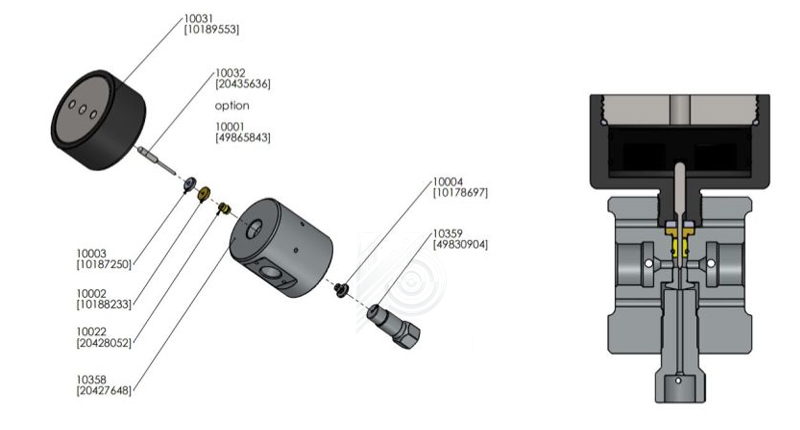

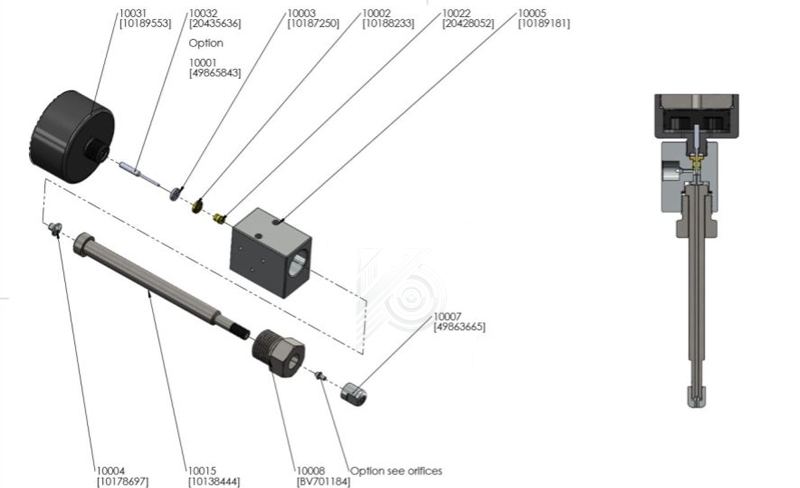

The part 20435636 is a precision stem for the pneumatic control valve used in 60 000 psi (4 100 bar) Waterjet Intensifier dump valves. It replaces the discontinued KMT stem 49894207 and features a flat-end, 3/8″ FS design machined from stainless steel for reliable actuation in both normally-open and normally-closed valve configurations.

Specifications

Function:Actuator stem for pneumatic dump/on-off valves in intensifier heads

Valve Compatibility:Normally-open and normally-closed 3-port pneumatic control valves

Stem Tip:Flat end, 90° angle for positive valve seating

Connection:3/8″ female straight (FS) port

Operating Pressure:Up to 60 000 psi (4 100 bar)

Installation & Maintenance

System Shutdown & Depressurization: Turn off the Waterjet Pump, isolate hydraulic and pneumatic supplies, and relieve all pressure.

Valve Removal: Unscrew the valve assembly from the intensifier manifold and disconnect any solenoid wiring.

Stem Extraction: Remove the old stem using appropriate tools; inspect the actuator bore and valve body for wear or scoring.

Stem Installation: Insert the new 20435636 stem, ensuring the flat end seats properly against the valve seat.

Reassembly & Testing: Reinstall the valve, reconnect air and electrical lines, then cycle at low air pressure (80–100 psi) before ramping to full operating pressure

Specifications

Function:Actuator stem for pneumatic dump/on-off valves in intensifier heads

Valve Compatibility:Normally-open and normally-closed 3-port pneumatic control valves

Stem Tip:Flat end, 90° angle for positive valve seating

Connection:3/8″ female straight (FS) port

Operating Pressure:Up to 60 000 psi (4 100 bar)

Installation & Maintenance

System Shutdown & Depressurization: Turn off the Waterjet Pump, isolate hydraulic and pneumatic supplies, and relieve all pressure.

Valve Removal: Unscrew the valve assembly from the intensifier manifold and disconnect any solenoid wiring.

Stem Extraction: Remove the old stem using appropriate tools; inspect the actuator bore and valve body for wear or scoring.

Stem Installation: Insert the new 20435636 stem, ensuring the flat end seats properly against the valve seat.

Reassembly & Testing: Reinstall the valve, reconnect air and electrical lines, then cycle at low air pressure (80–100 psi) before ramping to full operating pressure