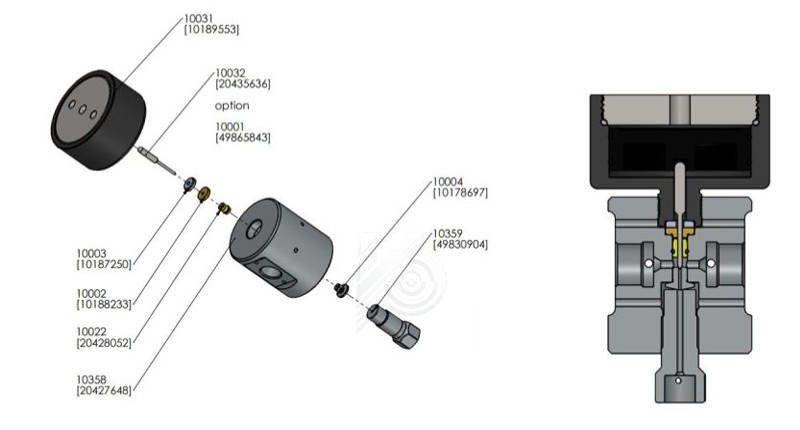

Pneumatic Valve Body 20427648 3 Port Waterjet Pump Parts

Pneumatic Valve Body 20427648 3 Port Waterjet-Pump-5-Axis-Waterjet-Cutting-Machine-For-Carbon-Fiber-p.html target='_blank'>Waterjet Pump Parts

The part 20427648 is a genuine OEM normally-open, 3-port round pneumatic dump valve body rated for 60 000 psi (4 100 bar) hydraulic intensifier systems on Waterjet Streamline machines. Constructed from stainless steel, it features two 3∕8″ HP side ports and a specialized bottom port for the VL49830904 adapter, providing reliable on/off dump control under rapid cycling.

Specifications

Ports:Two 3∕8″ HP side ports; bottom port for VL49830904 adapter

Pressure Rating:Up to 60 000 psi (4 100 bar) continuous operation

Valve Type:Normally-open, 3-port pneumatic control valve

Operating Medium:Clean, dry compressed air (80–120 PSIG) for actuation; hydraulic oil for dump

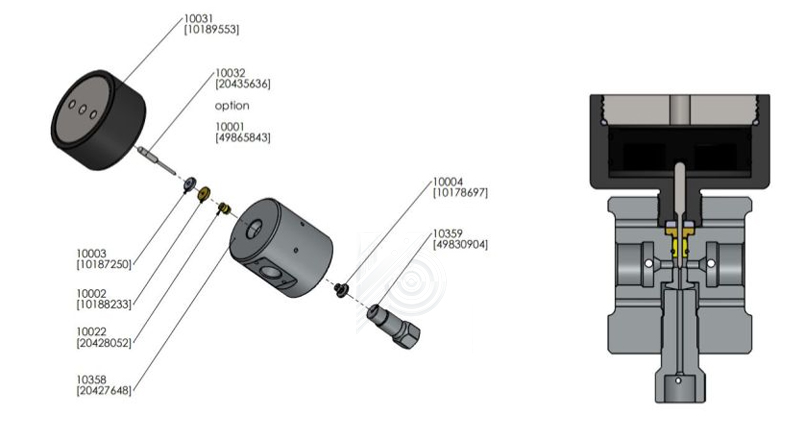

Installation & Maintenance

Depressurize System: Isolate and relieve both hydraulic and pneumatic pressures before servicing

Remove Old Valve: Unscrew the existing dump valve body from the intensifier manifold and disconnect air lines.

Inspect & Clean: Check the manifold ports and valve mounting surface for debris or wear; clean thoroughly.

Install 20427648: Thread the new valve body by hand, then torque to the manufacturer’s specification.

Reconnect Air Lines: Attach the actuator air supply, ensuring correct port orientation.

Functional Test: Apply low pneumatic pressure to verify venting and actuation before ramping to full operating pressure.

Specifications

Ports:Two 3∕8″ HP side ports; bottom port for VL49830904 adapter

Pressure Rating:Up to 60 000 psi (4 100 bar) continuous operation

Valve Type:Normally-open, 3-port pneumatic control valve

Operating Medium:Clean, dry compressed air (80–120 PSIG) for actuation; hydraulic oil for dump

Installation & Maintenance

Depressurize System: Isolate and relieve both hydraulic and pneumatic pressures before servicing

Remove Old Valve: Unscrew the existing dump valve body from the intensifier manifold and disconnect air lines.

Inspect & Clean: Check the manifold ports and valve mounting surface for debris or wear; clean thoroughly.

Install 20427648: Thread the new valve body by hand, then torque to the manufacturer’s specification.

Reconnect Air Lines: Attach the actuator air supply, ensuring correct port orientation.

Functional Test: Apply low pneumatic pressure to verify venting and actuation before ramping to full operating pressure.