Waterjet Seated Double Hand Yaskawa GP20 Robot Cutting For Helmets

Waterjet Seated Double Hand Yaskawa GP20 Robot Cutting For Helmets

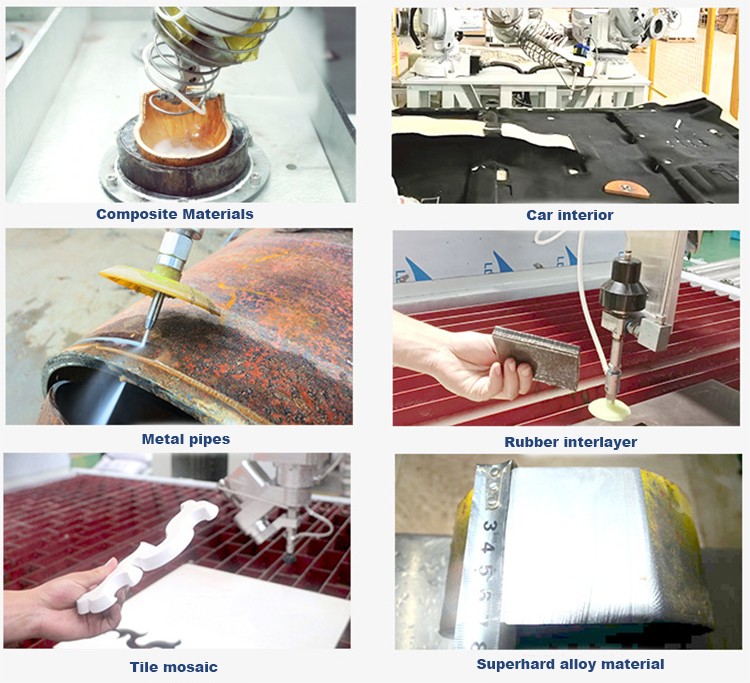

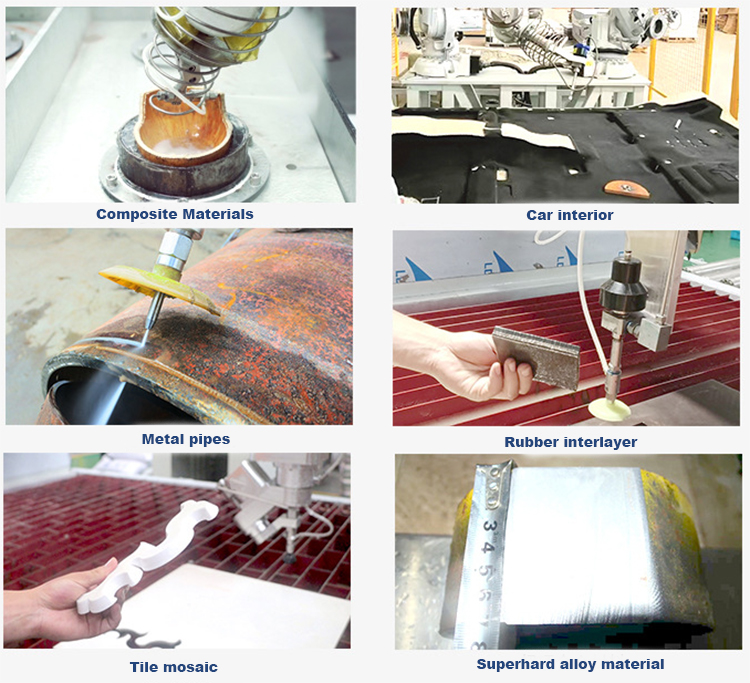

Robotic water jet cutting is specifically used in the following industries:

- Industrial manufacturing: Robotic Water Jet Cutting Machines can accurately cut various metal and non-metal materials, such as steel, aluminum, etc. In the automotive, aviation and other manufacturing industries, robotic water jet cutting machines are widely used in the cutting of high-precision parts to meet the high requirements for accuracy and operating speed.

- Medical technology: With the development of the medical industry, the requirements for equipment accuracy and operating speed are increasing. Robotic water jet cutting machines can accurately remove diseased tissues or tumors without damaging surrounding tissues due to their high precision and low temperature cutting characteristics. They can also be used to make medical devices such as micro-devices or stents.

- Military equipment: The military has extremely high requirements for the reliability and accuracy of equipment. In the manufacture of military equipment, robotic water jet cutting machines can cut high-precision, high-quality parts to meet the requirements of military equipment for accuracy and durability.

- Automotive interior cutting: Robotic water jet cutting has become the mainstream technology for automotive interior cutting. It can process various automotive interior materials, such as plastics, leather and fabrics, and cut parts of various shapes and sizes through a combination of high-pressure water flow and sand particles, improving cutting accuracy and efficiency while reducing labor costs and waste generation.

- Environmental protection industry: Robotic water cutting also plays an important role in some environmental protection applications. For example, when using high-pressure water cutting for fine 3D cutting tasks, it will not produce thermal fatigue and non-toxic smoke, which meets environmental protection requirements.

The Waterjet is a cutting-edge tool engineered to provide high-precision cutting solutions across a diverse range of materials. Utilizing ultra-high-pressure water streams, often mixed with abrasives, the waterjet delivers exceptional accuracy, smooth edges, and versatility in cutting tasks. It is capable of handling metals, ceramics, composites, glass, stone, and soft materials like rubber and foam without compromising the material's integrity.

One of the key advantages of the Waterjet is its cold-cutting technology, which eliminates heat-affected zones (HAZ) and ensures the material's structural properties remain intact. This feature makes it particularly valuable for industries requiring detailed, high-quality finishes, such as aerospace, automotive, construction, and custom manufacturing. Its capability to create intricate patterns and designs sets it apart from traditional cutting methods.

The waterjet system is designed for efficiency, incorporating features like user-friendly interfaces, low-maintenance components, and advanced water recycling systems to minimize waste and environmental impact. With adaptability for 2D and 3D cutting, the Waterjet meets the demands of modern manufacturing processes, offering a reliable and sustainable solution for precision cutting. Whether for large-scale industrial applications or detailed craftsmanship, the Waterjet stands as a versatile and efficient choice for manufacturers seeking superior performance.