Water Cutting Machine 3020 Flip Platform Abrasive Tile Waterjet Cutter Price

Water Cutting Machine 3020 Flip Platform Abrasive Tile Waterjet Cutter Price

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-3015 5 axis Water Jet |

|

Table Size |

3000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

3000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

75KW/100HP |

|

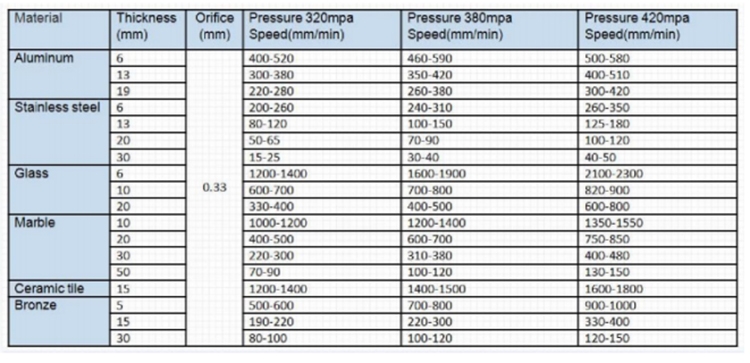

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

7.6L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

180L |

|

Size |

2120mm*1360mm*1510mm |

|

Weight |

1500kg |

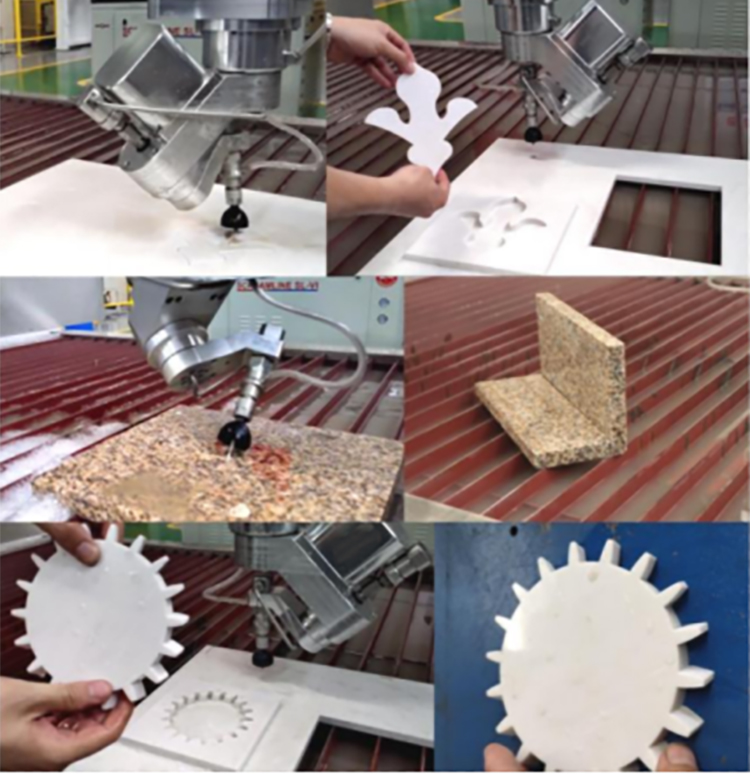

KUNDA’s Water Cutting Machines provide precision, versatility, and efficiency for a wide range of cutting applications across industries. Utilizing high-pressure water streams, often combined with abrasive materials like garnet, our water cutting machines can effortlessly cut through a diverse array of materials, including metals, stone, ceramics, glass, plastics, and composites. This cold-cutting method ensures that the material remains free from heat distortion, warping, or discoloration, making it ideal for applications that require both intricate cuts and high material integrity.

Engineered for superior precision, KUNDA’s Water Cutting Machines feature advanced CNC control systems, allowing for millimeter-level accuracy and repeatable cuts. With pressure capabilities up to 94,000 PSI, our systems are equipped to handle both lightweight and heavy-duty cutting tasks. Whether you are cutting thick metal plates, complex parts, or delicate stone carvings, KUNDA’s machines ensure a smooth, clean finish on every cut.

Built for durability and ease of maintenance, KUNDA’s water cutting machines are designed to provide long-lasting performance with minimal downtime. Key components, such as nozzles, high-performance pumps, and abrasive garnet, are easily replaceable, reducing maintenance costs and enhancing the machine's overall lifespan. Our systems are also energy-efficient, helping reduce operational costs while maintaining optimal cutting performance.

KUNDA offers comprehensive support, including installation, operator training, and ongoing maintenance services, to ensure that your water cutting machine operates at peak efficiency. Our team of experts is always ready to assist, ensuring that you get the most out of your investment.

Choose KUNDA’s Water Cutting Machines for a reliable, eco-friendly, and cost-effective cutting solution that meets the demanding requirements of industries like aerospace, automotive, manufacturing, and stone fabrication.

Other type of Waterjet Cutting Machine,please contact us!!!