Industry-news

How Fast Does Water Jet Cutting Cut Different Materials? What Is the Cutting Effect?

How Fast Does Water Jet Cutting Cut Different Materials? What Is the Cutting Effect?

Water jet cutting is known for its precision, versatility, and ability to cut through a variety of materials with exceptional speed and accuracy. At KUNDA, we offer advanced Water Jet Cutting Machines that deliver top-tier performance, ensuring fast cutting speeds and outstanding results for different materials. Whether you need to cut metal, stone, glass, ceramics, or composites, KUNDA's machines can meet your needs with tailored solutions that offer superior cutting effects and efficiency.

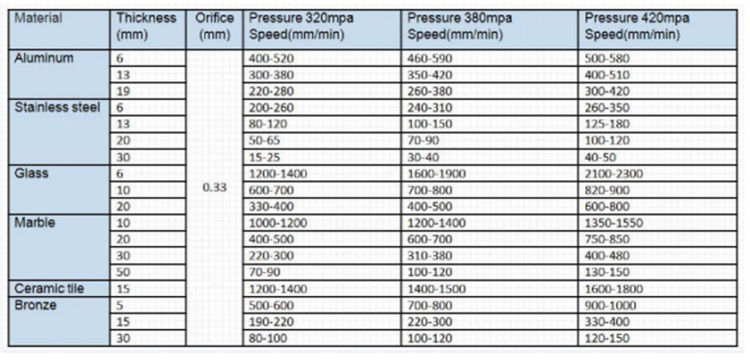

Cutting Speed Across Different Materials

One of the key advantages of water jet cutting is its ability to cut materials quickly and efficiently. The cutting speed depends on the material's hardness, thickness, and composition, but KUNDA’s Water Jet Machines offer impressive speed across a variety of materials.

-

Metals: For metals like stainless steel, aluminum, and titanium, KUNDA’s Water Jet Cutters offer fast cutting speeds, especially with thinner sheets. For example, our machines can cut stainless steel up to 6 inches thick at a speed of 1-2 inches per minute, while thinner materials can be cut at even higher speeds. The high-pressure water, combined with abrasive garnet, allows for clean cuts without causing heat-affected zones (HAZ), preserving the material’s properties.

-

Stone: Water jet cutting is ideal for hard materials like granite and marble. Our machines can cut through stone up to 6 inches thick with impressive speed, maintaining high-quality edges and minimal waste. The high-pressure water jet ensures that even intricate patterns are cut quickly while maintaining the stone’s integrity.

-

Glass: For glass cutting, KUNDA’s machines achieve precise, smooth edges at speeds of up to 2-3 inches per minute for standard glass thicknesses. The cold cutting process prevents cracking or thermal stress, ensuring a flawless finish.

-

Composites and Plastics: KUNDA’s Water Jet Machines also excel in cutting composite materials like carbon fiber and fiberglass, as well as plastics. Depending on thickness, the cutting speed can range from 1-3 inches per minute. Water jet cutting provides clean edges and is ideal for materials that can be affected by heat-based cutting methods.

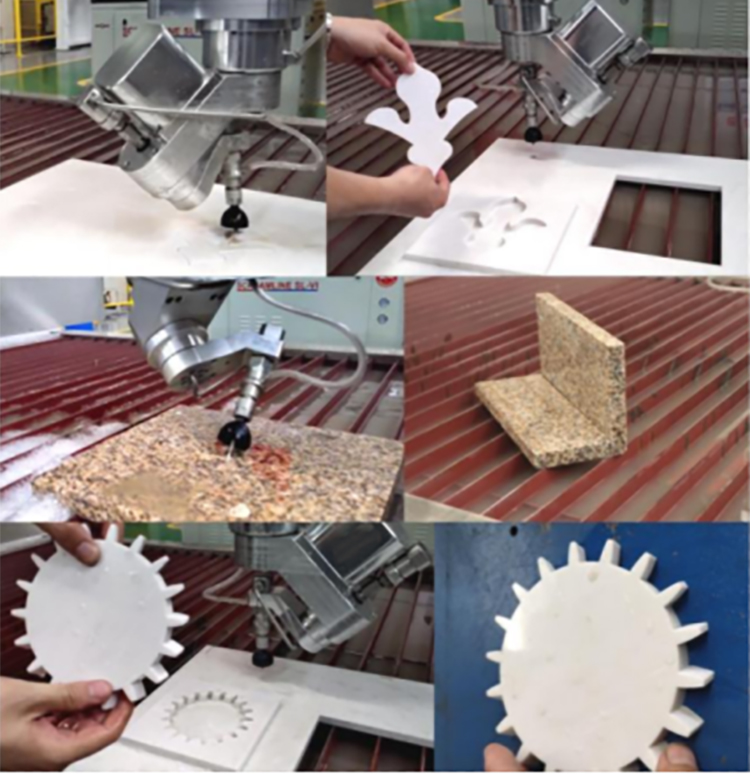

Cutting Effect: Clean, Smooth, and Precise Edges

The cutting effect of KUNDA Water Jet Machines is exceptional, delivering clean, precise, and smooth edges with minimal burrs or surface damage. Unlike traditional cutting methods that use heat, water jet cutting is a cold cutting process, meaning there is no heat-affected zone (HAZ), which preserves the material’s structural integrity and appearance. This is especially crucial when working with materials like metal and glass, where heat can distort or affect material properties.

Whether cutting thick metals or delicate stones, KUNDA’s water Jet Cutters provide high-quality results every time, ensuring that edges are smooth, and the material is undamaged. The precision offered by our machines also ensures that designs and shapes are cut to exact specifications, whether for aerospace, automotive, or architectural applications.

Customizable Water Jet Cutting Solutions by KUNDA

At KUNDA, we understand that every business has unique cutting needs. That’s why we offer customized water jet cutting machines tailored to your specific requirements. Whether you need specialized cutting heads, higher pressure systems, or custom-sized machines to handle large or irregularly shaped materials, KUNDA can provide a solution that fits your production needs.

Our team works closely with customers to design and build custom water jet cutting machines that meet the exact material specifications, cutting speeds, and cutting effects required for your projects. From adjusting nozzle sizes to integrating additional features like automated loading systems, KUNDA offers fully tailored solutions to optimize efficiency and productivity.

Why Choose KUNDA’s Water Jet Cutting Machines?

- High Cutting Speeds: Fast cutting without compromising quality, tailored to different materials.

- Superior Cutting Effects: Clean, smooth edges with minimal material waste.

- Custom Solutions: Tailored machines and configurations to meet specific material and production needs.

- Energy-Efficiency: Lower operational costs with high productivity.

- Durability and Reliability: Machines designed to last with low maintenance requirements.

KUNDA is your trusted partner for water jet cutting solutions. Whether you are cutting metals, stone, glass, or composites, our advanced technology ensures faster production times and superior cutting effects. With customizable options, we ensure that your water jet cutting machine is perfectly suited to your specific needs. Contact us today to discuss your requirements, and let us provide the cutting-edge technology you need for precision, speed, and efficiency.