Industry-news

What is an abrasive waterjet?

What is an abrasive waterjet?

An abrasive waterjet is a cutting technology that uses high-pressure streams of water mixed with abrasive particles to cut hard materials with exceptional precision. This process combines the versatility of waterjet cutting with the added power of abrasives to allow cutting of harder materials such as metals, ceramics, stone and composites with no heat-affected zones and complex shapes being handled easily. Abrasive waterjets have applications from aerospace to automotive industries and offer many benefits that include clean cuts without heat-affected zones and handling complex shapes with no heat-affected zones and the capability of handling complex shapes being addressed effectively.

This article will explore what an abrasive waterjet is, how it operates, its advantages and the materials it can cut through.

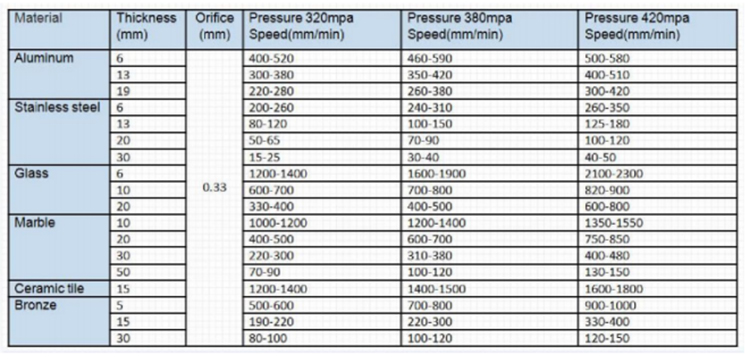

How Does an Abrasive Waterjet Work? An abrasive waterjet works by combining high-pressure water (typically between 30,000 to 90,000 psi) with an abrasive material like garnet or aluminum oxide to produce a powerful stream that passes through a small nozzle to form a focused jet that cuts through various materials with ease.

An abrasive Waterjet Cutting System comprises of four basic components. These components include:

High-pressure pump: This creates the high-pressure water necessary for cutting. Abrasive delivery system: Abrasive is mixed into the water stream before reaching the nozzle.

Cutting nozzle: This directs this mixture of water and abrasives onto material being cut.

As water and abrasives strike the material, they erode its surface gradually to produce an exact cut without using heat, making this method an excellent way of cutting materials that are susceptible to thermal damage.

What Materials Can an Abrasive Waterjet Cut Through?

Abrasive waterjets are extremely versatile tools, capable of cutting through various materials including:

Metals: Abrasive waterjets can be used to cut stainless steel, aluminum, titanium and carbon steel among other metals, often at thicknesses that range from thin sheets to thick plates.

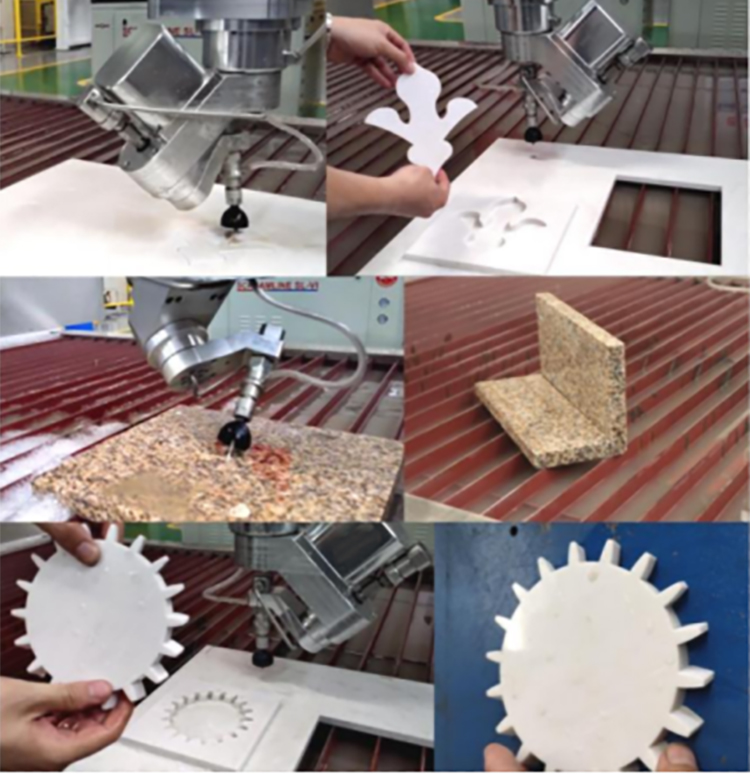

Stone and Tile: Materials like granite, marble and ceramic tiles can easily be cut using abrasive waterjets for applications in architecture, interior design and construction. This makes them the ideal material choice.

Composite Materials: Carbon fiber, fiberglass and other composites can be cut without delamination or damage caused by other cutting methods, which is common when it comes to other methods of cutting.

Plastics: Waterjets can cut plastics such as PVC, acrylic and polycarbonate with great accuracy.

Abrasive waterjets can cut through glass and ceramic materials without leaving cracks or chips behind, making them an excellent solution for architectural glass cutting and custom designs.

Benefits of Abrasive Waterjet Cutting

Abrasive waterjets offer several key advantages over conventional cutting methods:

1. Accuracy and Cleanliness

Abrasive waterjets can produce extremely accurate cuts with tight tolerances of up to 0.005 inches, making them suitable for cutting intricate shapes, patterns and detailed designs.

2. No Heat-Affected Zone (HAZ)

Waterjet cutting does not produce heat like laser or plasma cutting methods do, thus eliminating any risk of warping, melting or material degradation due to an HAZ. This feature makes waterjet an excellent way to cut heat-sensitive materials like metals and composites with no risk of heat warping, melting or degradation.

3. Versatility WaterJet Cutters can cut through various materials, including metals, stone, glass, plastics and composites - making them extremely flexible tools suitable for use across industries such as aerospace, automotive, construction and manufacturing.

4. Minimal Material Waste

Waterjet cutting processes produce very minimal material waste due to their precise cutting method and narrow kerf width (cut width), as most of it is utilized efficiently reducing overall costs.

5. No Tool Wear

As opposed to mechanical cutting methods, abrasive waterjets do not rely on traditional cutting tools like blades or saws, meaning no tool wear. This results in lower maintenance costs and more consistent cutting performance over time.

Abrasive waterjet cutting is an eco-friendly method because it produces no fumes, toxic gases or hazardous waste products; making the process safe to be used in environments sensitive to pollution.

Abrasive waterjet cutting applications span across industries for diverse uses. Some examples are:

Aerospace applications involve cutting engine components, structural components, and turbine blades with great accuracy. Automotive manufacturing operations produce custom parts such as trims and chassis components while architectural projects utilize cutting stone, marble and tile cuts as architectural projects require.

Metalworking involves cutting sheet metal, plates, and structural parts for industrial use. Signage and Art: Utilizing materials like metal and stone to craft customized signs, logos, and artistic designs that stand out.

Conclusion Its An abrasive waterjet is an advanced cutting technology that combines high-pressure water with abrasive particles for efficient cutting across various materials. Due to its precision, versatility and ability to avoid heat damage it makes an excellent choice for industries requiring intricate designs with high-quality cuts such as metal cutting. Cutting through metal, stone, composites or glass; an abrasive waterjet offers an eco-friendly cutting solution for modern manufacturing needs and design applications.

If you need an advanced cutting solution for your project, abrasive waterjet cutting may be an ideal choice. Able to tackle challenging materials while producing superior results with maximum efficiency and accuracy, this form of waterjet technology offers maximum cutting performance and efficiency.