Industry-news

What Materials Can Be Processed by Robotic Water Jet Cutting Machines?

What Materials Can Be Processed by Robotic Water Jet Cutting Machines?

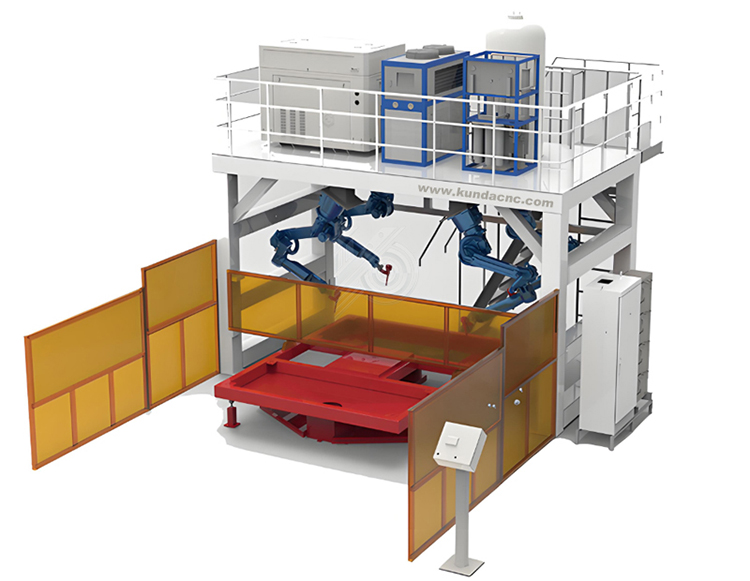

Robotic water jet cutting machines are a game-changing solution for many industries that require precision and versatility in their cutting processes. Powered by high-pressure water, sometimes mixed with abrasives, these machines can process a wide variety of materials with superior accuracy and minimal waste. This article explores the materials that can be processed by robotic water jet cutting machines, the cutting effects, and the key advantages these machines offer.

Materials Processed by Robotic Water Jet Cutting Machines

Robotic water jet cutting machines are highly versatile and can handle a wide range of materials across various industries. Below is a breakdown of the most commonly processed materials:

1. Metals

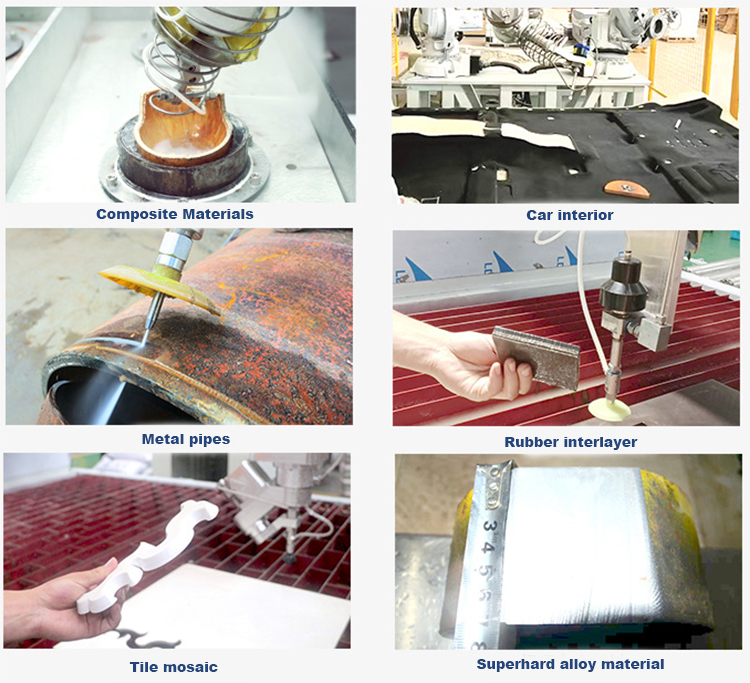

Metals are one of the most common materials cut with Water Jet Technology, thanks to their strength and thickness. Robotic water jet cutting machines can cut through various metal types, including:

- Steel (including stainless steel and mild steel)

- Aluminum and its alloys

- Titanium and titanium alloys

- Brass and Copper

- Nickel Alloys (such as Inconel)

Cutting Effect: The result is clean, burr-free edges without heat-affected zones (HAZ), which helps preserve the integrity of the material, preventing any distortion.

2. Stone and Ceramics

Robotic Water Jet Cutters are also ideal for processing natural and engineered stone materials, including granite, marble, quartz, and ceramics. Water jet cutting is especially beneficial for stone and ceramics due to its ability to make intricate cuts without causing cracks or fractures.

- Granite

- Marble

- Limestone

- Ceramic Tiles

Cutting Effect: Produces precise, smooth cuts with minimal waste, preserving the aesthetic quality of the stone and creating intricate designs for architectural or decorative applications.

3. Composites

Water jet cutting machines are also excellent for cutting composite materials, which can be challenging with traditional cutting methods. Composites such as carbon fiber and fiberglass are often used in aerospace, automotive, and manufacturing applications.

- Carbon Fiber

- Fiberglass

- Kevlar

- Aramid Fiber

Cutting Effect: Robotic water jet cutting machines create sharp, clean cuts with minimal fiber distortion, making them perfect for delicate composite materials.

4. Glass

Water jet cutting is ideal for glass due to its precision and the fact that it generates no heat, preventing cracks or breakage. Robotic water Jet Cutters can handle various types of glass, from decorative glass to automotive glass.

- Tempered Glass

- Laminated Glass

- Acrylic and Polycarbonate Sheets

Cutting Effect: Produces smooth, precise cuts without the risk of cracks, ensuring high-quality results for delicate glass applications.

5. Plastics and Rubber

Robotic water jet cutting machines are often used to cut various types of plastic and rubber, providing clean cuts for parts that need to be flexible yet durable. This makes water jet technology particularly useful in industries such as packaging, automotive, and electronics.

- Acrylic (PMMA)

- Polycarbonate

- PVC

- Nylon

- Rubber

Cutting Effect: The machine provides fast, accurate cuts while maintaining the material's integrity. The absence of heat ensures that the material remains unaffected by thermal damage, making it ideal for plastics and rubber products.

6. Foams and Textiles

Water jet cutting is widely used in industries that require soft materials, such as foam or textiles, to be cut with high precision. This includes everything from insulation materials to clothing and upholstery fabrics.

- Polyurethane Foam

- Latex Foam

- Fabrics (Cotton, Polyester, etc.)

- Carpet

Cutting Effect: Clean, precise cuts with no fraying of edges, ideal for industries such as bedding, automotive seating, and clothing.

7. Food Products

Robotic water jet cutting is increasingly being used in the food industry to process soft or delicate food products, offering a precise and hygienic cutting solution.

- Meats

- Vegetables

- Cheese

- Frozen Foods

Cutting Effect: Water jet cutting provides precise, clean cuts without compromising food texture or quality, ensuring minimal contamination and maximum hygiene during food processing.

Advantages of Robotic Water Jet Cutting Machines

Robotic water jet cutting machines offer numerous advantages that make them an attractive choice for manufacturers across different industries. Here are some key benefits:

1. Precision and Accuracy

The robotic arm and advanced control systems ensure extremely precise cuts, even for complex designs. The machine can follow programmed paths with exact accuracy, making it perfect for intricate shapes and tight tolerances.

2. Minimal Material Waste

Since water jet cutting is a cold cutting process, there is no heat generated, which means there is no thermal distortion or expansion. This helps to preserve the material's integrity, reducing waste and scrap.

3. Versatility

Robotic water Jet Cutters can handle a broad range of materials, making them a versatile solution for businesses dealing with multiple material types. Whether it’s hard metals, soft plastics, stone, or rubber, water jet cutting is highly adaptable.

4. No Heat-Affected Zones

Since the cutting process doesn’t involve heat, it prevents the formation of heat-affected zones (HAZ) that can occur with laser or plasma cutting. This preserves the mechanical properties of materials like metal and composite materials.

5. Complex and Intricate Cuts

The robotic arm allows the water Jet Cutter to operate in multiple directions and angles, enabling it to produce highly intricate and complex shapes that would be difficult or impossible to achieve with traditional cutting methods.

6. Low Maintenance

Water jet cutting machines are typically low-maintenance, requiring fewer repairs than some traditional cutting methods. The use of water and abrasives ensures minimal wear and tear on the cutting tools.

7. Customizable to Specific Needs

Robotic water jet cutting machines can be customized to meet specific production requirements. Whether you need different cutting speeds, sizes, or the ability to handle various material thicknesses, these machines can be tailored to suit your needs.

Conclusion

Robotic water jet cutting machines are incredibly versatile and can process a wide range of materials, including metals, composites, glass, plastics, stone, and even food. The cutting effects are clean, precise, and efficient, with minimal material waste and no heat distortion. These machines offer significant advantages over traditional cutting methods, making them a popular choice across industries like aerospace, automotive, manufacturing, construction, and food processing.

With their customizable features, robotic water jet cutting machines are an essential tool for any business that values high precision, versatility, and efficiency in their production processes.

If you are interesting in it,please contact us, there have different model of robot Waterjet Machine!