Abrasive Water Jet Machining Flip Platform 3020 Fiberglass Waterjet Cutting Machine Supplier

Abrasive Water Jet Machining Flip Platform 3020 Fiberglass Waterjet Cutting Machine Supplier

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-3015 5 axis Water Jet |

|

Table Size |

3000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

3000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

75KW/100HP |

|

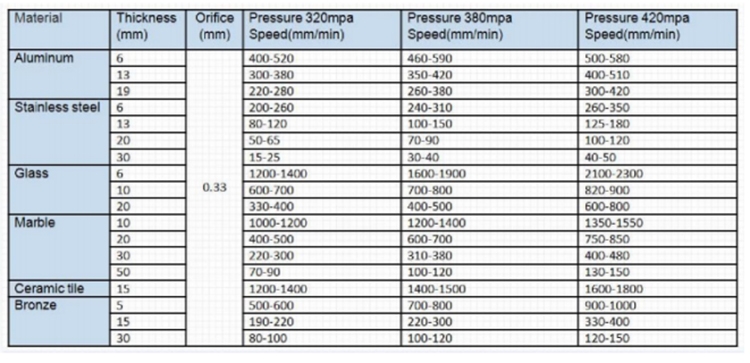

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

7.6L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

180L |

|

Size |

2120mm*1360mm*1510mm |

|

Weight |

1500kg |

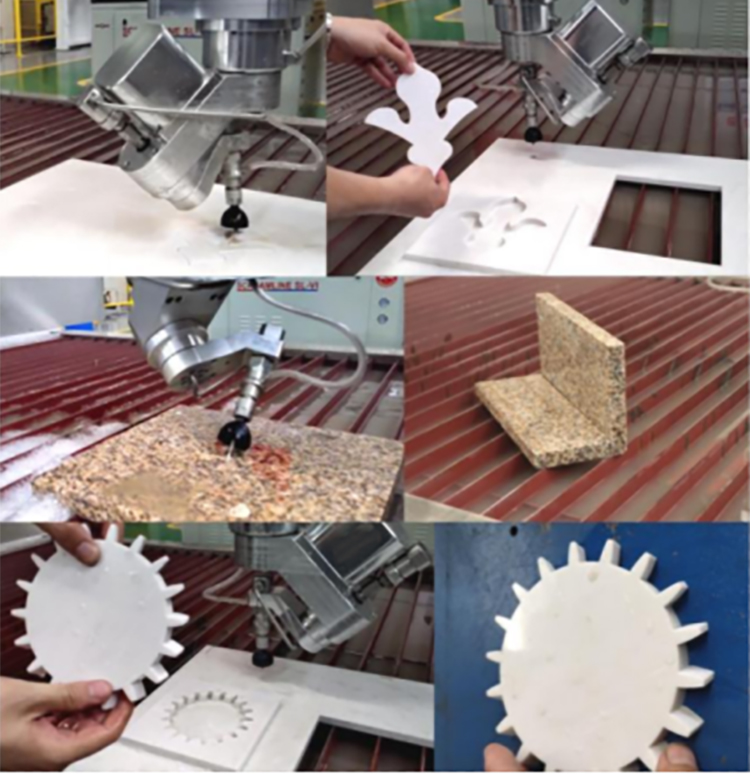

The Abrasive Water Jet Machining system is an advanced, precision-focused cutting technology designed for high-performance material processing across industries such as aerospace, automotive, construction, and custom manufacturing. By using a powerful stream of high-pressure water mixed with fine abrasive particles, this system achieves smooth, precise cuts on a wide range of materials, including metals, ceramics, glass, composites, and stone. Unlike traditional cutting methods, abrasive water jet machining generates no heat, preventing thermal distortion and ensuring clean, undamaged edges.

One of the key advantages of Abrasive Water Jet Machining is its ability to handle both delicate and extremely hard materials with equal efficiency. Its CNC-controlled interface allows for intricate cuts, detailed shapes, and complex geometries, making it perfect for high-precision applications that require minimal material waste. Whether cutting thick metal sheets or creating custom stone designs, this system delivers results with unmatched accuracy and quality.

Engineered for long-term, heavy-duty use, the Abrasive Water Jet Machining system features a robust construction that ensures reliable performance even in demanding environments. With an intuitive, user-friendly interface, operators of all skill levels can easily manage and program the machine for various tasks, optimizing workflow and productivity.

Low-maintenance and energy-efficient, this system is a cost-effective solution for businesses looking to enhance production capabilities while maintaining high standards of quality. The Abrasive Water Jet Machining system combines precision, durability, and versatility, making it an essential tool for cutting-edge industrial applications.

Other type of Waterjet Cutting Machine,please contact us!!!