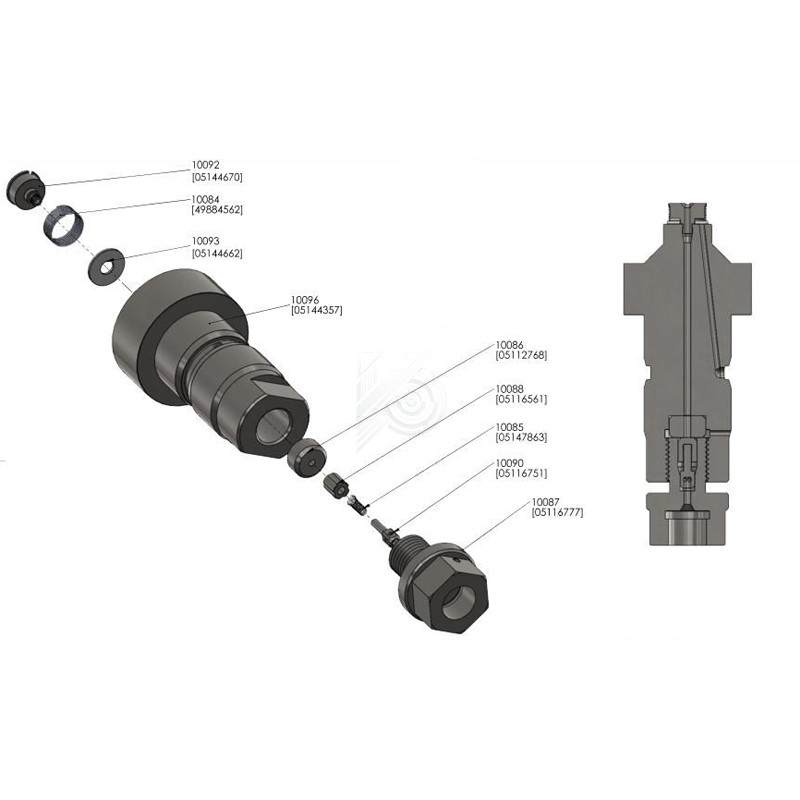

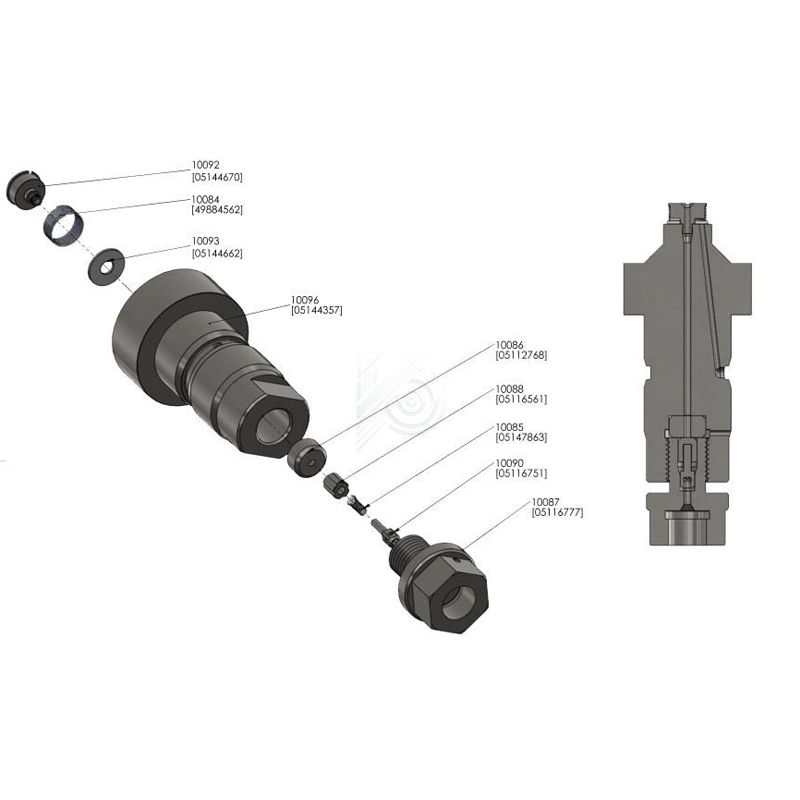

Sealing Head Inlet Poppet Retainer 05144670 Waterjet Parts

Sealing Head Inlet Poppet Retainer 05144670 Waterjet Parts

The Sealing Head Inlet Poppet Retainer 05144670 is an OEM poppet valve retainer used in KMT Streamline intensifier sealing heads with .875″ plungers, ensuring proper seating and retention of the inlet poppet under high‑pressure cycling up to 60 000 psi (4 100 bar).

Installation & Maintenance

1. Depressurize & Drain: Fully relieve system pressure and drain the intensifier2. Disassemble Sealing Head: Remove the sealing head assembly per KMT service manual

3. Remove Old Retainer: Extract the worn retainer with a suitable puller; inspect and clean the bore

4. Install New Retainer: Press the 05144670 retainer into place, ensuring flush seating

5. Reassemble & Test: Reinstall poppet and head components; repressurize gradually and verify leak‑free operation at full pressure、

INQUIRY