5 Axis Waterjet Machining 100kg Flip Platform Lager Ceramics Abrasive Water Jet Cutter

5 Axis Waterjet Machining 100kg Flip Platform Lager Ceramics Abrasive Water Jet Cutter

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-3015 5 axis Water Jet |

|

Table Size |

3000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

3000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

75KW/100HP |

|

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

7.6L/min |

|

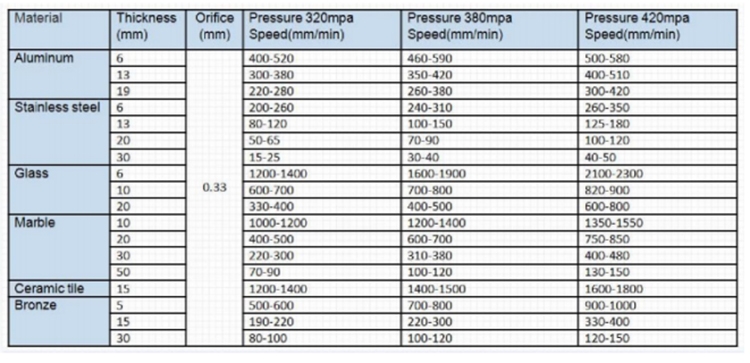

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

180L |

|

Size |

2120mm*1360mm*1510mm |

|

Weight |

1500kg |

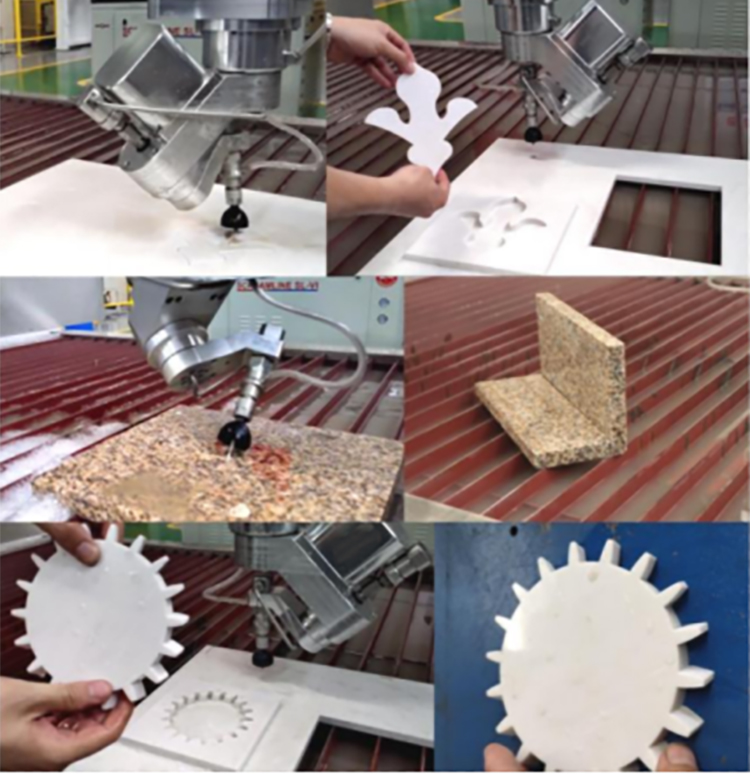

The 5 Axis Waterjet Machining system is an advanced cutting solution designed to perform highly intricate and multi-dimensional cuts with superior accuracy. Unlike traditional Waterjet Cutters, which operate in a 2D plane, the 5-axis capability allows the machine to cut at precise angles along five different axes. This makes it ideal for complex geometries, beveled edges, and 3D shapes, catering to industries such as aerospace, automotive, architecture, and custom manufacturing, where precision and versatility are crucial.

Using a high-pressure water stream combined with fine abrasive particles, the 5 Axis Waterjet Machining system is capable of slicing through a wide variety of materials—including metals, ceramics, glass, composites, and stone—without generating heat, which prevents thermal distortion and preserves material integrity. Its advanced CNC control system enables smooth transitions between angles, allowing for the creation of complex components and reducing the need for secondary finishing.

This machine excels in handling intricate designs and challenging materials, making it suitable for applications that demand both accuracy and flexibility. With its user-friendly interface, operators can easily program and adjust cutting parameters, even for intricate multi-dimensional tasks. The robust design of the 5 Axis Waterjet Machining system ensures reliability and durability, allowing for continuous, high-quality performance in demanding industrial environments.

For businesses looking to expand their production capabilities, this machine offers a cost-effective solution that improves workflow efficiency and opens new possibilities for high-precision projects. The 5 Axis Waterjet Machining system combines cutting-edge technology with unmatched precision, making it an essential asset for industries aiming for excellence in multi-dimensional cutting.

Other type of Waterjet Cutting Machine,please contact us!!!