Water Jet Cnc Machine Price 3015 Cantilever Flip Platform Fiberglass Waterjet Cutter

Water Jet Cnc Machine Price 3015 Cantilever Flip Platform Fiberglass Waterjet Cutter

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-3015 5 axis Water Jet |

|

Table Size |

3000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

3000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

75KW/100HP |

|

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

7.6L/min |

|

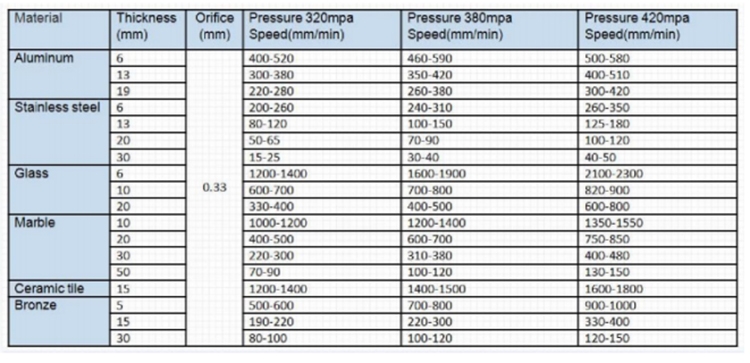

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

180L |

|

Size |

2120mm*1360mm*1510mm |

|

Weight |

1500kg |

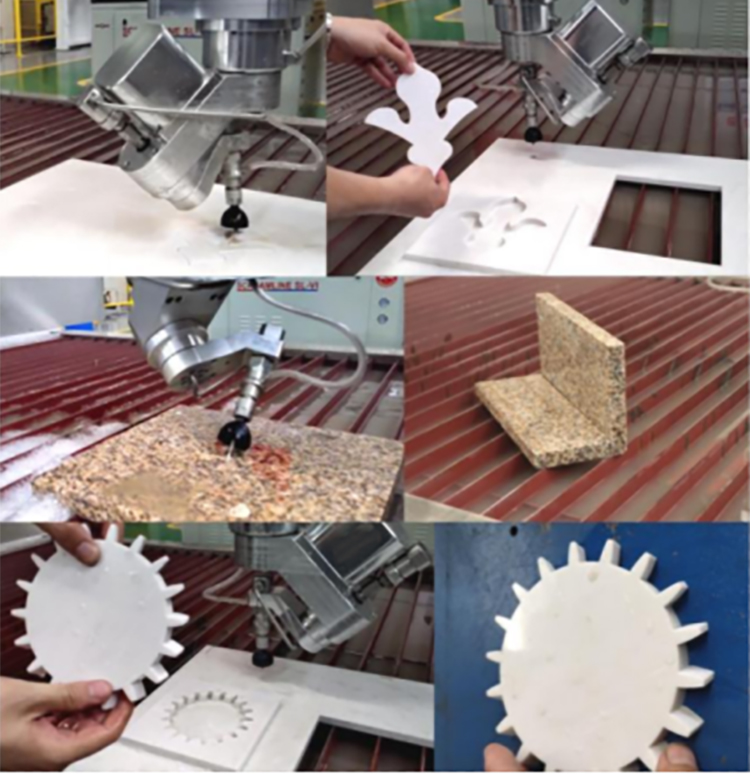

KUNDA’s Water Jet CNC Machines combine cutting-edge technology with precision engineering to provide highly efficient and versatile cutting solutions for various industries. These machines utilize high-pressure water, often mixed with abrasive materials like garnet, to cut through a wide range of materials, including metals, ceramics, glass, stone, and composites. The water jet process eliminates the need for heat, preventing thermal damage, warping, or material deformation, making it perfect for intricate and delicate cuts.

Our Water Jet CNC Machines are equipped with advanced CNC control systems, offering precise, repeatable cuts with millimeter-level accuracy. With pressure capabilities reaching up to 94,000 PSI, KUNDA’s machines can handle both light and heavy-duty cutting applications. This makes them ideal for industries such as aerospace, automotive, metalworking, and stone fabrication, where high precision and quality are essential. Whether you’re cutting thick metal plates or designing intricate stone carvings, our water jet CNC machines deliver exceptional results every time.

Engineered for durability and minimal maintenance, KUNDA’s Water Jet Machines come with easily replaceable components, such as nozzles, abrasive garnet, and high-pressure pumps, to ensure long-lasting performance and reduced downtime. The machines are also energy-efficient, helping businesses lower operational costs while maintaining peak cutting performance.

KUNDA is committed to providing full support for our customers, offering machine installation, operator training, and ongoing maintenance services. With our expertise and comprehensive service, you can rely on KUNDA’s Water Jet CNC Machines for consistent, high-quality results. Whether you are handling complex designs, large-scale production, or cutting a variety of materials, KUNDA’s water jet machines offer the precision, versatility, and reliability you need to stay ahead in today’s competitive market.

Other type of Waterjet Cutting Machine,please contact us!!!