Industry-news

What Type of Pump Does a Water Jet Use?

A Water Jet cutting machine relies on high-pressure pumps to generate the force necessary to cut through a range of materials. At its heart lies pressurized water that ensures precise and efficient cutting. There are two primary types of pumps used in such machines: intensifier pumps and direct drive pumps - each offering specific advantages that suit different applications.

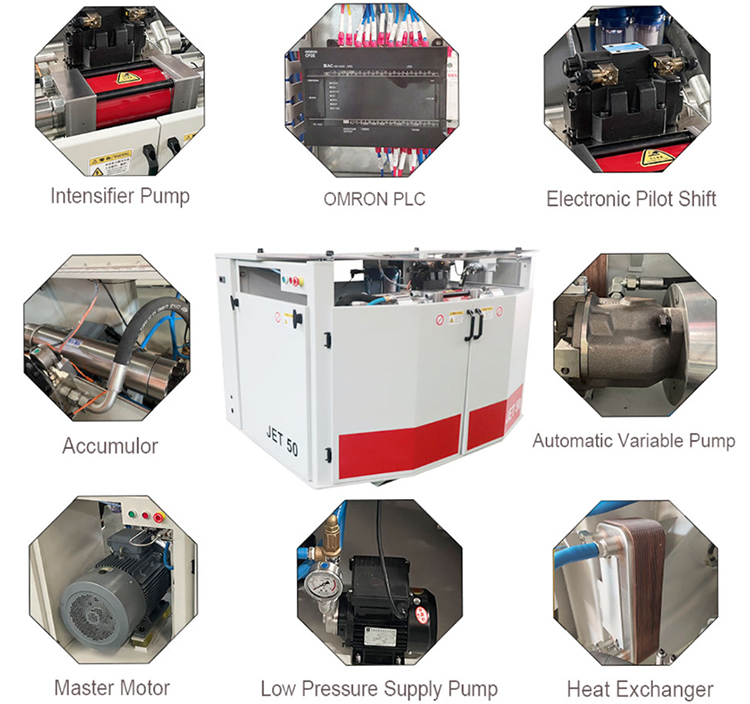

1. Intensifier Pumps

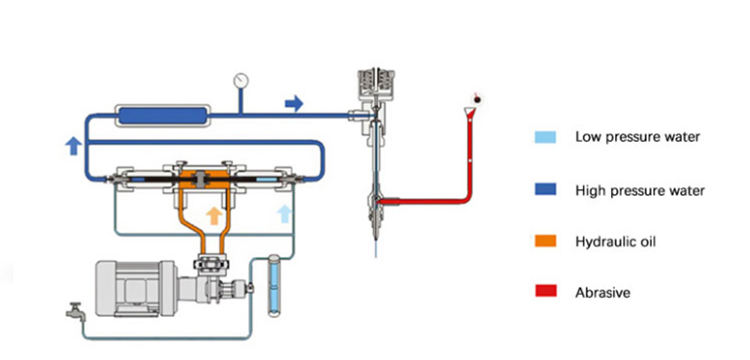

Intensifier pumps use hydraulic pressure to create high-pressure water. Their system includes a hydraulic pump with a piston that pressurizes a separate chamber with water pressurization - this process allows intensifier pumps to produce extraordinarily high water pressure levels - sometimes reaching up to 90,000 psi (6200 bar).

Advantages

High Pressure Capability: Allows for faster cutting speeds by reaching ultra-high pressures, consistently providing water pressure at precise cutting levels for higher precision cutting. Consistent Performance: Provides stable water pressure that maintains precise cutting at high precision levels. Longer Lifespan: Components designed for durability and extended use are best used.

Best Used To Cut Thick Metals, Stone and Ceramics.

Heavy-duty industrial applications requiring continuous operation. Direct Drive Pumps.

How they Work

Direct drive pumps utilize an electric motor to directly drive a crankshaft that pressurizes water. In contrast to intensifier pumps, direct drive systems do not rely on hydraulic components and may therefore be simpler and more cost-efficient in certain cases. They typically operate between 40,000-60,000 psi (2,800-4100 bar).

Benefits :

Energy Efficient: Reduced electric costs in comparison with intensifier pumps. Lower Maintenance Costs: Fewer moving parts reduce maintenance requirements. More Cost Effective Than Their Counterparts Best Suited for Applications Requiring High Pressure.

Cutting soft materials such as rubber, foam and plastics. Small-scale operations where lower pressure is enough.

Which Pump Is Appropriate for My Water Jet? Deciding between An Intensifier pump or direct drive pump will depend on the materials being cut as well as your business requirements and operational needs.

For materials requiring powerful cutting capabilities such as thick and hard materials, an intensifier pump may be ideal. When cutting soft materials that consume less energy consumption, direct drive pumps offer cost-effective cutting power solutions.

Both pumps can be found across numerous industries such as aerospace, automotive, metal fabrication and manufacturing; providing precision and efficiency when cutting applications.

Conclusion

Water Jet Cutting Machines utilize intensifier or direct drive pumps to generate the high-pressure water needed for cutting. Intensifier pumps are best suited to heavy-duty cutting of thick materials while direct drive pumps may be more energy-efficient and suitable for lighter materials. Selecting the appropriate pump for your Water Jet System ensures optimal cutting performance, cost effectiveness and long-term reliability.