News

Introduction to Waterjet Cutting Machine

Introduction to WaterJet Cutting Machine

Custom Water Jet Machine is a versatile and precise material cutting process that uses a high-pressure water stream, usually in combination with an abrasive, to cut a wide range of materials. The operation is based on the principle of erosion; water is accelerated through a narrow nozzle at a speed that erodes the workpiece, allowing for complex cuts without heat-induced changes or distortions.

Waterjet Cutting Operation Flow

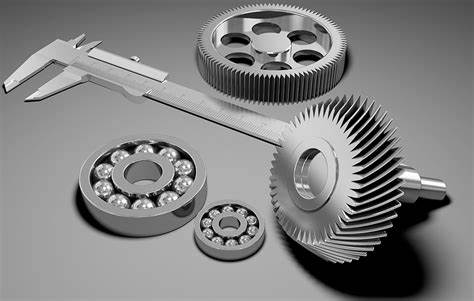

Custom Waterjet involves a complex set of mechanical devices that use a high-pressure water jet or a mixture of water and abrasive to cut a wide range of materials. Its core components include a high-pressure pump, a resonator to generate the water stream, an articulated cutting head to manipulate the water stream, and a control system for precise movement. During operation, the material is placed on a support table and the cutting head moves over it according to a programmed pattern. Initially, the pump generates pressurized water, directs it through the resonator, and the speed is increased, turning it into a concentrated cutting water stream. If abrasives are required for harder materials, they are introduced into a mixing chamber before the nozzle directs the jet injected into the sharpener onto the workpiece. This cohesive action enables precise cuts, guided by software to ensure accuracy, minimizing waste, and unparalleled versatility in shaping materials.

Key Benefits of Waterjet Cutting

The effectiveness of Custom Waterjet Cutting Machine lies in its precision and versatility, as it can expertly process a range of materials, from metals to ceramics, without compromising detail. Notably, the value of the process is that it does not generate a lot of heat, effectively eliminating thermal deformation or hardening that could compromise the integrity of the material. Additionally, this cutting method is environmentally friendly, producing only clean cuts and no hazardous waste. For example, the complex designs of aerospace components can be achieved with impeccable precision through waterjet cutting while retaining the properties of the sensitive materials used.

Industry Applications of Waterjet Cutting

Electric Waterjet has found a place in various industries due to its precision and versatility. In the manufacturing industry, the technology is essential for producing specialized parts that require precise specifications and smooth surfaces. The aerospace and automotive industries rely on waterjet cutting to create complex parts where precision is critical; it enables engineers to create complex geometries without introducing heat-affected zones or material warping. Additionally, artists and designers often use water jet cutting when making custom creations, as the process gives them the freedom to cut a wide range of materials into unique shapes and intricate designs, allowing for truly custom artwork and decorative items.

Comparison of Water Jet Cutting to Other Technologies

Garnet Abrasive Waterjet compares favorably to laser and plasma cutting methods in terms of precision, material versatility, and environmental impact. While laser cutting can precisely shape metals, but can have difficulty with reflective materials or produce heat-affected zones, water jet cutting leaves no thermal distortion and is able to process nearly all materials, from metals to composites, without the risk of warping or melting. While plasma cutting is fast and efficient for thicker sheet metal, it lacks the finesse that can be achieved with A Water Jet, especially when complex contours or a high level of detail is required. From an environmental perspective, water jet cutting uses natural abrasives and water, producing minimal hazardous waste compared to the fumes and gases that can be emitted during plasma and laser processes. This method is particularly popular in situations where the integrity of the material must be maintained without altering its inherent structure, such as cutting intricate patterns in stone or glass, where precise edges and sensitive surface finishes are critical.

Maintenance and Safety Considerations for Waterjet Cutting Machines

Regular maintenance is essential to ensure the longevity and efficient operation of Garnet Water Jet Cutting Machine. This includes regular inspection and cleaning of the high-pressure pump, abrasive delivery system, and cutting head components to prevent clogging and wear. In addition, replacing worn seals and filters is essential to maintain optimal performance. Safety precautions are equally important; operators must wear protective glasses and ear protection due to the loud noise and potential particle ejection. Ensuring that safety guards are in place and that the cutting area is clear of unnecessary personnel during operation helps minimize the risk of accidents. Regular training on emergency procedures further enhances the safe use of waterjet technology.

Future Prospects of Waterjet Technology

Garnet Waterjet Cutting Machine technology is on the verge of several future technological advances that will improve precision and sustainability. Innovations such as 3D Waterjet cutting are expected to revolutionize complex geometries, making it possible to effectively process complex designs that are difficult to accomplish with traditional methods. In addition, environmental concerns have driven research into environmentally friendly abrasives and recycling systems that reduce waste. In terms of emerging applications, from the aerospace industry, which requires custom composite trimming, to the art industry, which uses it to create sensitive sculptures, waterjet cutting is increasingly being adopted because of its versatility and fineness. Additionally, the medical device manufacturing industry may soon take advantage of these advances, requiring impeccable cutting of materials used in prosthetics or surgical instruments without the introduction of heat-affected zones that could change the material's properties.

Q&A on Waterjet Cutting Technology

Granite Water Cutting Machine is a versatile technology capable of cutting a wide range of materials, including metals, glass, stone, composites, and ceramics. Some machines can cut parts up to several inches thick, depending on the pressure and composition of the water jet. Due to its high speed and precision, this method can be seamlessly integrated into large-scale production settings. Uniquely, it also excels at handling heat-sensitive materials because it does not generate high temperatures that can alter or damage such substrates. Cost factors for Waterjet Services typically include the type and thickness of material being cut, the complexity of the design, and the time required for the job. As a cold cutting process, waterjet can produce clean edges without heat deformation or hardening, demonstrating its wide range of applications across a variety of industries.