News

What Are the Advantages of Fully Enclosed Abrasive Water Jet Cutting Machines?

What Are the Advantages of Fully Enclosed Abrasive Water Jet Cutting Machines?

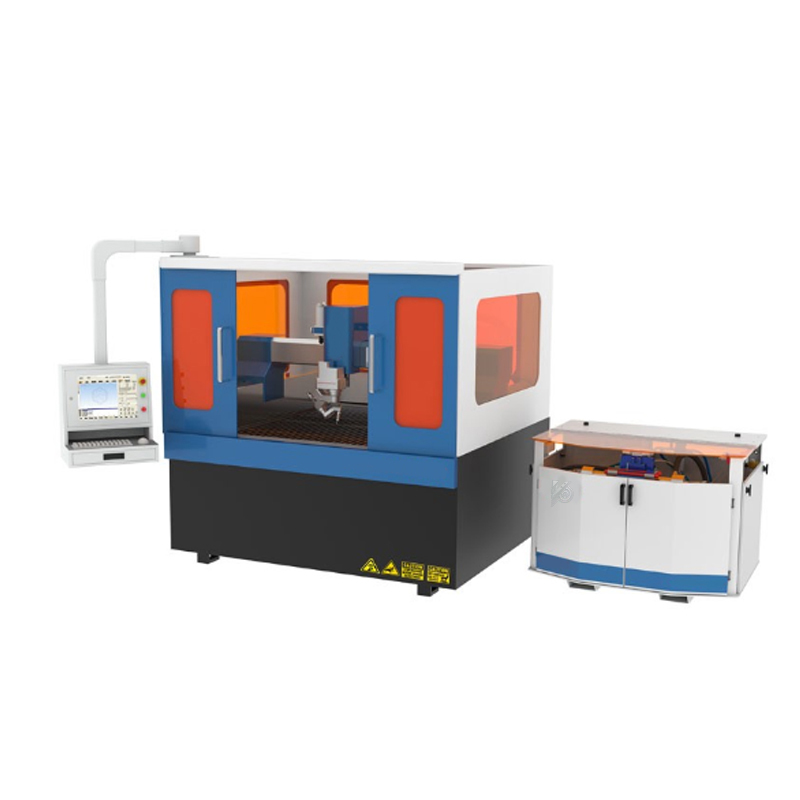

Fully enclosed Abrasive Water Jet Cutting Machines are an excellent solution for industries that prioritize safety, cleanliness, and efficiency. At KUNDA, we design and manufacture high-performance water jet cutting machines that not only provide exceptional precision but also offer enhanced features for a safer and cleaner working environment. Here are some of the key advantages of our fully enclosed abrasive water jet cutting machines, and how KUNDA’s custom solutions can meet your specific cutting needs.

1. Enhanced Safety

Safety is a top priority in any industrial environment, and fully enclosed abrasive water jet cutting machines are specifically designed to ensure a safe working atmosphere. The full enclosure prevents flying debris, water splashes, and abrasive particles from becoming hazards to operators. This protective barrier significantly reduces the risk of injury, making it an ideal solution for businesses where safety regulations and employee protection are a priority. The enclosed design also ensures that high-pressure Water Jets are safely contained within the machine, further reducing the chances of accidents.

2. Cleaner Cutting Environment

A fully enclosed cutting environment ensures that water and abrasive materials remain contained, minimizing the mess and spillages that can occur in open machines. By trapping water vapor and airborne particles within the enclosure, our abrasive water jet cutting machines maintain a cleaner, more organized workspace. This is especially beneficial in industries like aerospace, automotive, and metalworking, where cleanliness is critical to both the manufacturing process and the quality of the finished product. The controlled environment also reduces the need for frequent cleanup, enhancing overall productivity.

3. Reduced Noise Levels

The high-pressure cutting process in A Water Jet machine can generate significant noise, which can be uncomfortable for operators and may require additional noise-reducing measures. With KUNDA’s fully enclosed machines, the noise level is greatly reduced. The enclosure acts as a sound barrier, keeping noise contained within the machine, resulting in a quieter working environment. This makes the machine more comfortable for operators and improves the overall working conditions, especially in facilities that require a quieter production process.

4. Improved Environmental Control

Enclosed abrasive water jet cutting machines help control the environmental conditions within the workspace. They contain water mist and other airborne particles, preventing them from spreading throughout the shop floor. This results in better air quality, reduced contamination risks, and an overall healthier environment for your workforce. By keeping contaminants in check, businesses can maintain compliance with workplace safety standards, particularly in industries that deal with hazardous materials or sensitive production processes.

5. Customization Options for Specific Needs

At KUNDA, we understand that every business has unique needs when it comes to water jet cutting. That's why we offer customizable fully enclosed abrasive water jet cutting machines that can be tailored to your specific requirements. Whether you need a larger cutting bed for handling bigger materials, additional filtration systems for cleaner operation, or enhanced safety features to comply with industry standards, KUNDA’s team can design and build the perfect machine for you. Our expertise in customization ensures that your machine will meet both your production demands and safety needs.

Why Choose KUNDA for Your Fully Enclosed Abrasive Water Jet Cutting Machines?

- Increased Safety: Our fully enclosed machines prevent accidents by containing debris, water, and abrasives.

- Cleaner Work Environment: The enclosed system helps maintain a tidy and organized workspace with minimal mess.

- Noise Reduction: The enclosure minimizes sound, making the workspace more comfortable and reducing the need for additional noise-control measures.

- Improved Air Quality: Contained water mist and particles lead to a healthier working environment.

- Tailored Solutions: KUNDA offers fully customizable machines to meet your specific cutting needs, ensuring maximum efficiency and safety.

KUNDA is committed to providing advanced Water Jet Cutting Technology that enhances safety, cleanliness, and operational efficiency. Our fully enclosed abrasive water jet cutting machines provide the ideal solution for businesses seeking to improve their work environment while maintaining high-quality, precise cutting capabilities. Contact KUNDA today to learn more about our customizable machines and how we can help you achieve a cleaner, safer, and more efficient cutting process.

If you are interesting in this machine,please contact us!