Small Waterjet Machine For Sale Fully Enclosed Automotive Glass 1010 Water Jet Cutter Price

Small Waterjet Machine For Sale Fully Enclosed Automotive Glass 1010 Water Jet Cutter Price

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-2015 5 axis Water Jet |

|

Table Size |

2000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

2000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

30KW/40HP |

|

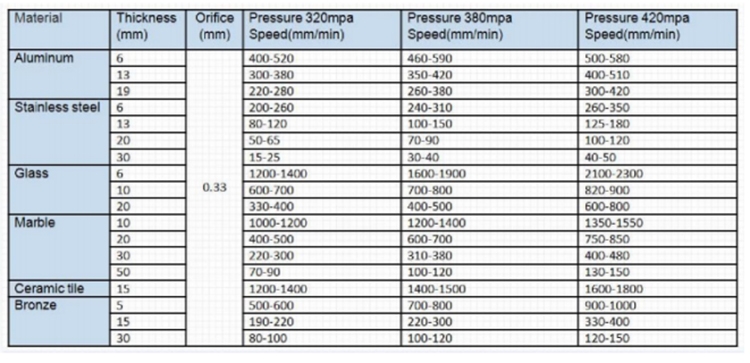

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

3.8L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

150L |

|

Size |

20020mm*1260mm*1310mm |

|

Weight |

1300kg |

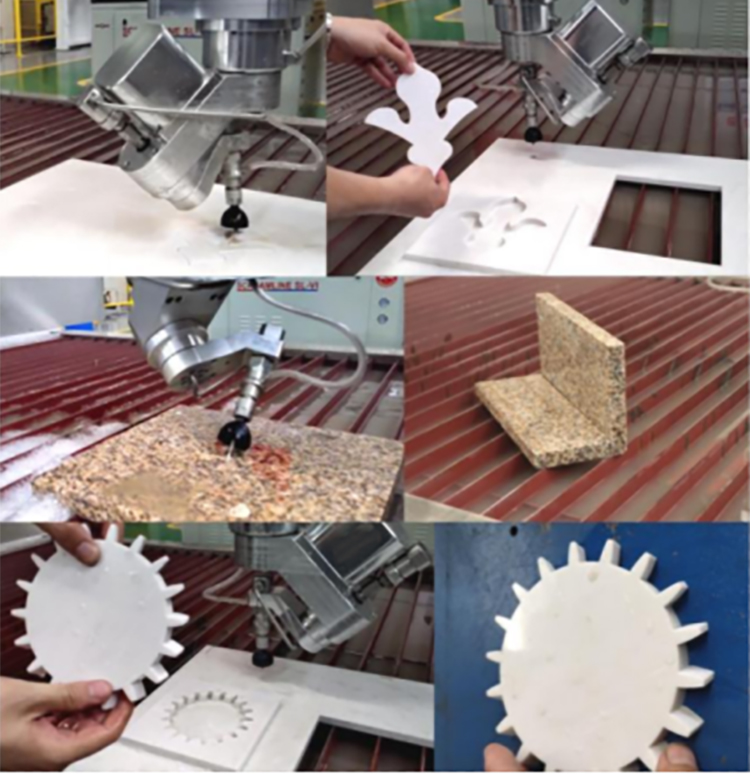

KUNDA’s Small Waterjet Machines offer an ideal solution for businesses seeking high-precision, compact cutting technology for a variety of materials. Designed for smaller-scale operations, these machines provide all the power and versatility of larger water jet systems but in a more compact, space-efficient design. Perfect for cutting metals, plastics, stone, glass, ceramics, and composites, KUNDA’s Small Waterjet Machines offer exceptional cutting speed and precision without the need for heat-based processes, ensuring a clean, smooth finish every time.

Equipped with advanced CNC control systems, our Small Waterjet Machines are capable of achieving millimeter-level accuracy, making them perfect for intricate cuts, complex shapes, and detailed designs. With pressure capabilities up to 94,000 PSI, these machines can handle a wide range of materials with ease, from delicate thin metals to tougher stone slabs. The ability to cut without heat distortion means that materials retain their structural integrity and finish, making it ideal for applications where precision and quality are paramount.

Despite their compact size, KUNDA’s Small Waterjet Machines are built for durability and long-term reliability. The machines are designed for easy operation and minimal maintenance, with replaceable components like nozzles and abrasive garnet ensuring that the machine operates at peak performance for longer. Their energy-efficient design helps reduce operational costs while maintaining cutting power and precision.

Whether you are cutting prototypes, custom parts, or small production runs, KUNDA’s Small Waterjet Machines offer a cost-effective and versatile solution for businesses in industries such as aerospace, automotive, architecture, and metal fabrication. With our expert support and customization options, we can help you find the perfect water jet cutting solution to meet your specific needs.

Other type of WaterJet Cutting Machine,please contact us!!!