Stone Bridge Cutting Machine Fully Enclosed 1015 Abrasive Ceramics Abrasive Waterjet Cutter

Stone Bridge Cutting Machine Fully Enclosed 1015 Abrasive Ceramics Abrasive Waterjet Cutter

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-2015 5 axis Water Jet |

|

Table Size |

2000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

2000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

30KW/40HP |

|

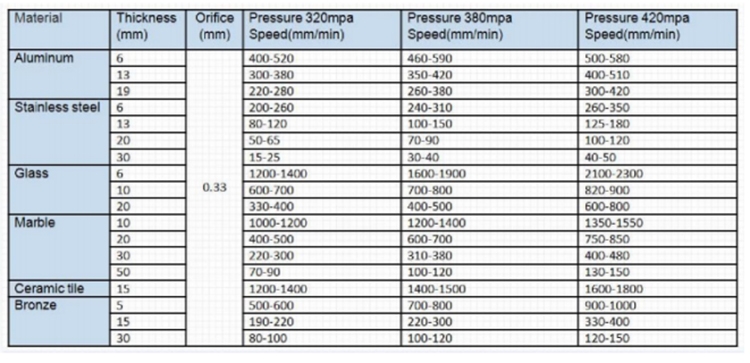

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

3.8L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

150L |

|

Size |

20020mm*1260mm*1310mm |

|

Weight |

1300kg |

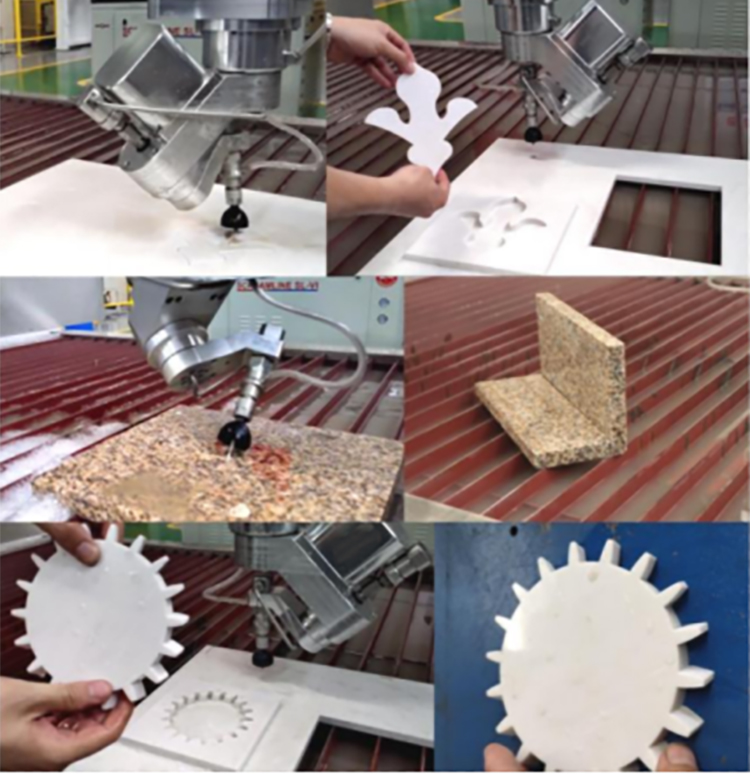

KUNDA’s Stone Bridge Cutting Machines are advanced solutions designed for cutting large stone slabs with precision, speed, and efficiency. Ideal for materials such as granite, marble, quartz, and limestone, our bridge cutting machines are engineered to deliver clean, smooth cuts with minimal waste and maximum accuracy. With the ability to handle heavy stone slabs, these machines are perfect for both small-scale workshops and large stone fabrication facilities.

Our Stone Bridge Cutting Machines feature a robust, bridge-style structure that ensures stability and precision during the cutting process. Equipped with advanced CNC control systems, these machines offer highly accurate, repeatable cuts, allowing operators to execute intricate designs, complex shapes, and detailed patterns. The high-performance motor and cutting head are capable of cutting through stone quickly and efficiently, making them perfect for applications in architecture, countertops, and sculptures.

KUNDA’s Stone Bridge Cutting Machines are built to handle tough materials with ease, providing cutting speeds that reduce production time while maintaining the highest quality standards. The machines are also designed with minimal maintenance in mind, with easy-to-replace components like saw blades, motors, and pump systems, ensuring long-lasting performance and reduced downtime.

Our water-based cutting technology provides a cold-cutting process, preventing heat damage, warping, or discoloration that can occur with traditional cutting methods. This ensures that each stone retains its natural beauty and structural integrity, making it perfect for high-end stonework and custom designs.

KUNDA also offers tailored solutions for customers who require specific features or capabilities. Whether you need a larger cutting bed, enhanced motor power, or customized software integration, we can build a Stone Bridge Cutting Machine that meets your unique requirements.

For businesses in the stone fabrication industry, KUNDA’s Stone Bridge Cutting Machines deliver precision, reliability, and efficiency, ensuring your cutting processes are both cost-effective and high-quality.

Other type of WaterJet Cutting Machine,please contact us!!!