Sealing Head Flat Outlet Poppet 05116561 Water Jet Parts Supplier

Sealing Head Flat Outlet Poppet 05116561 Water Jet Parts Supplier

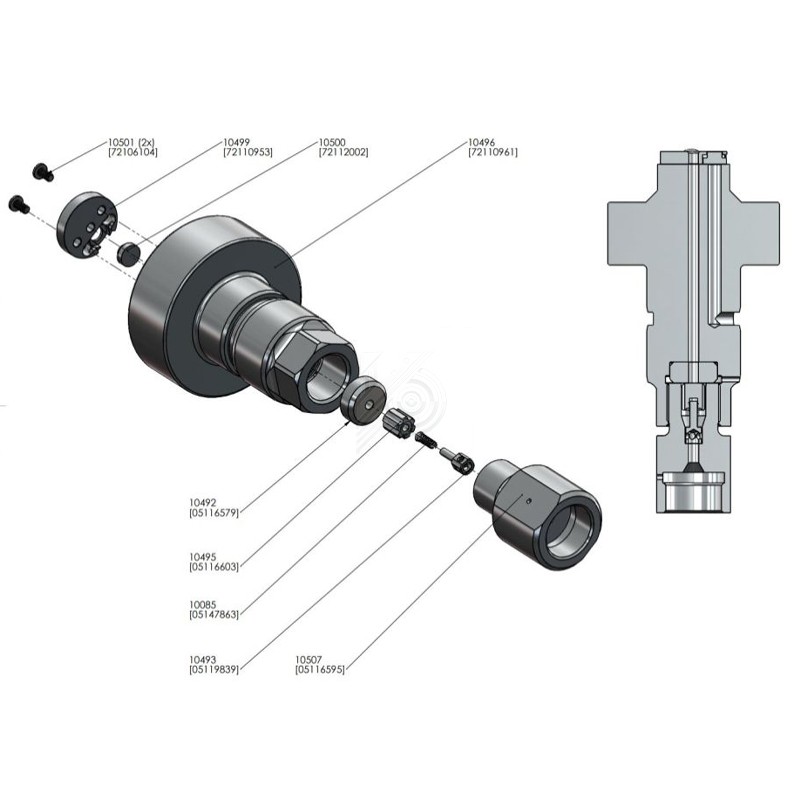

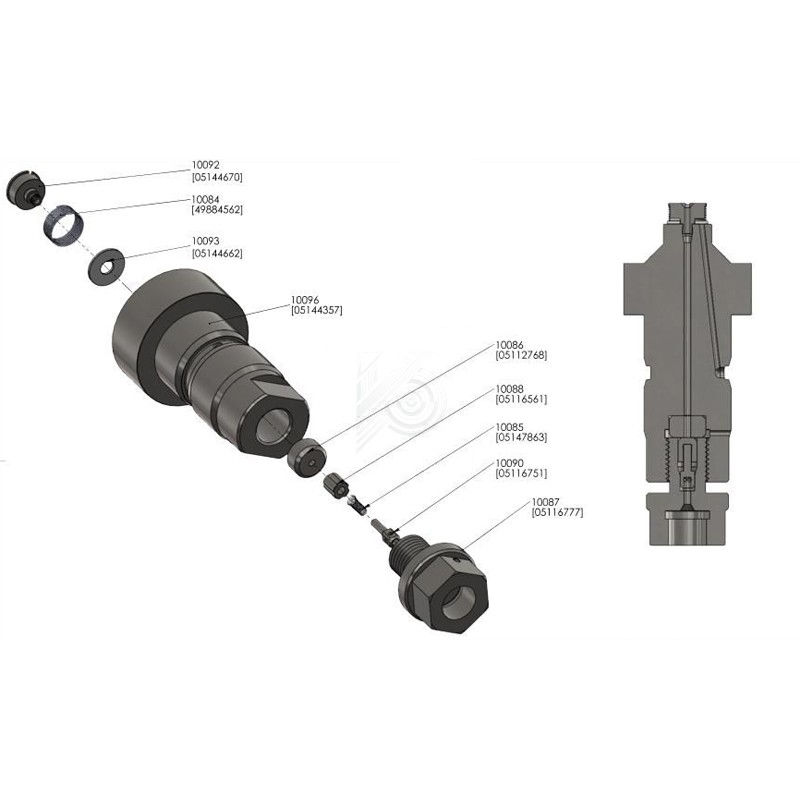

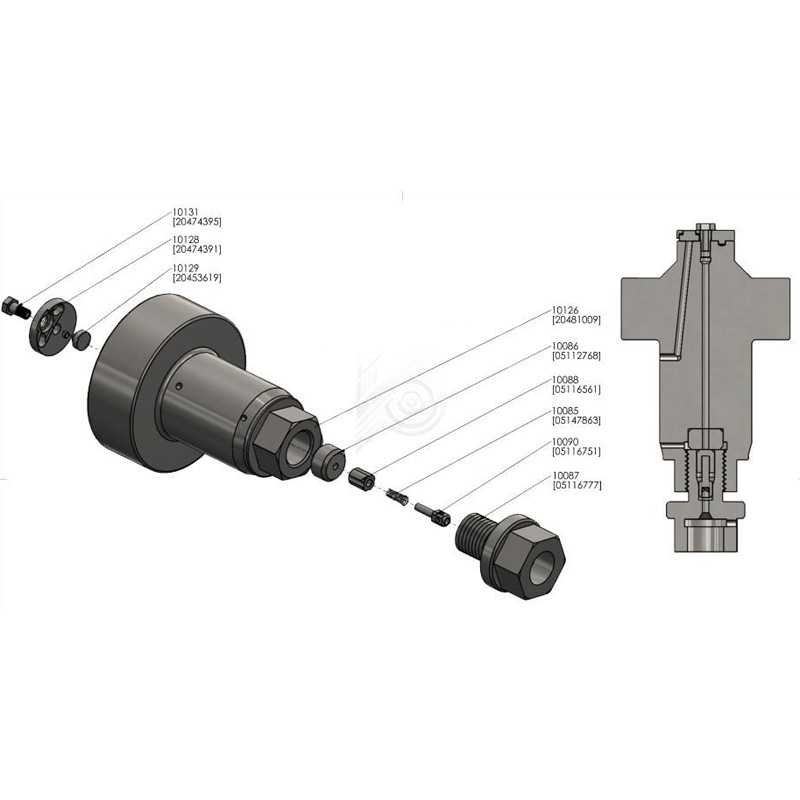

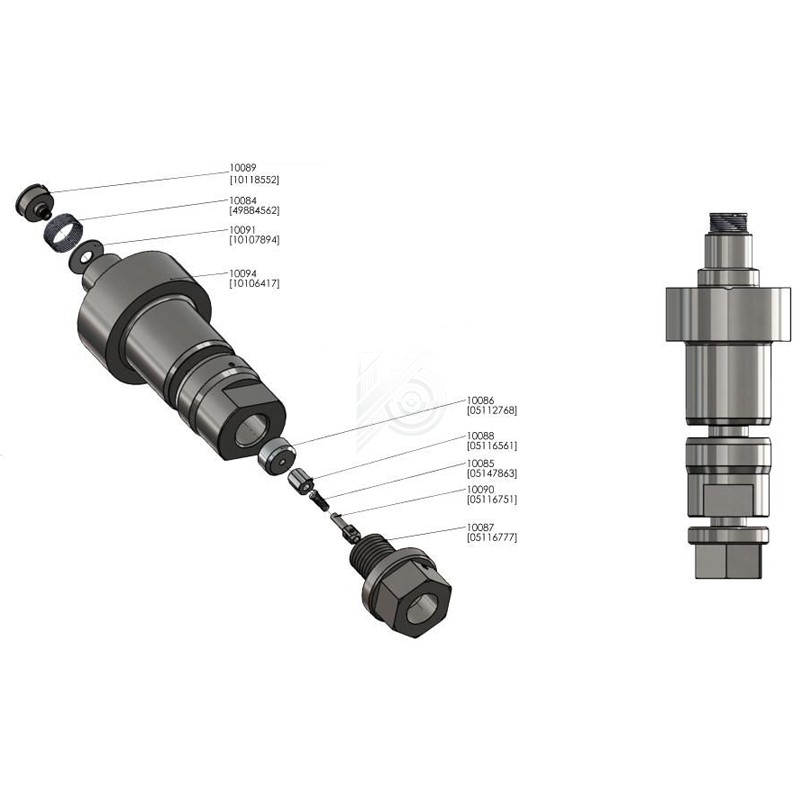

Specifications

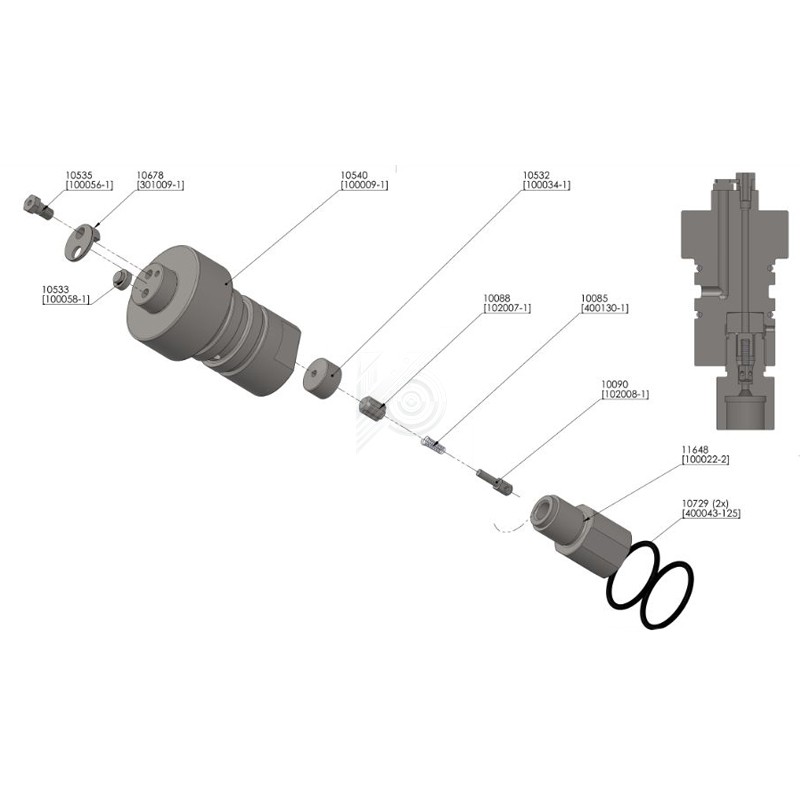

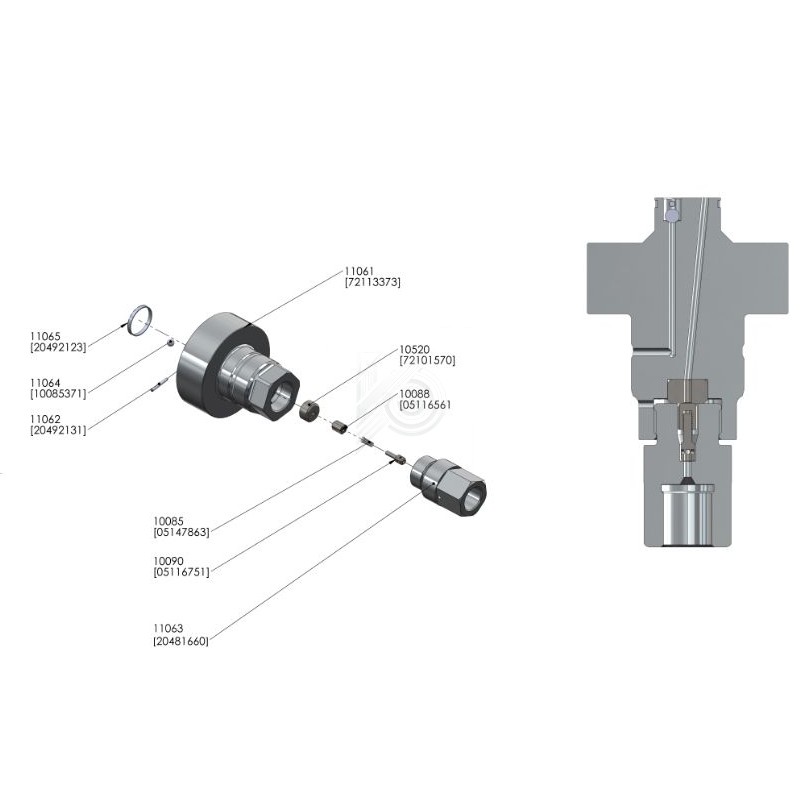

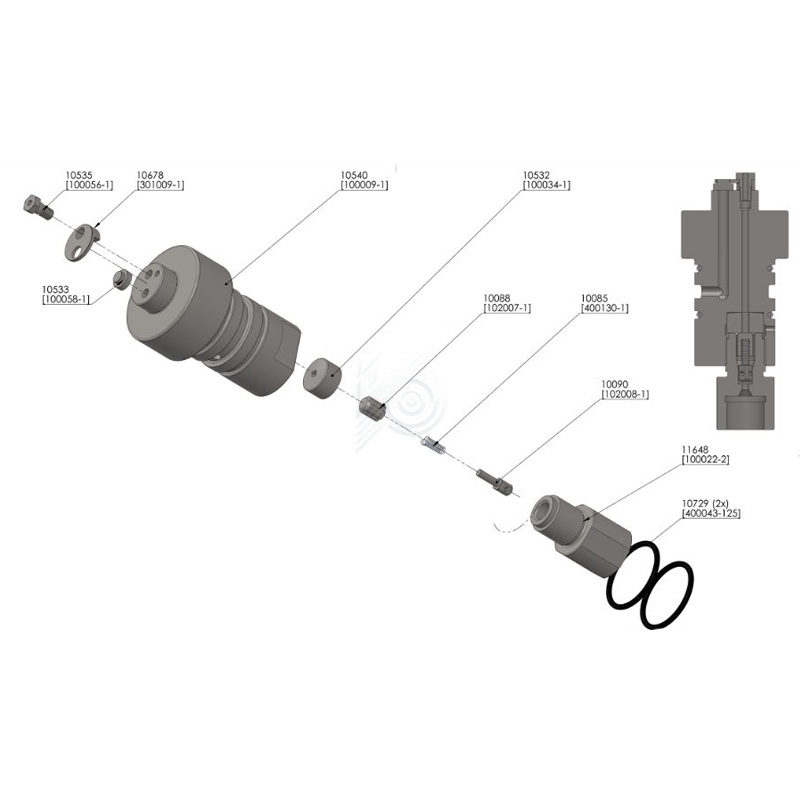

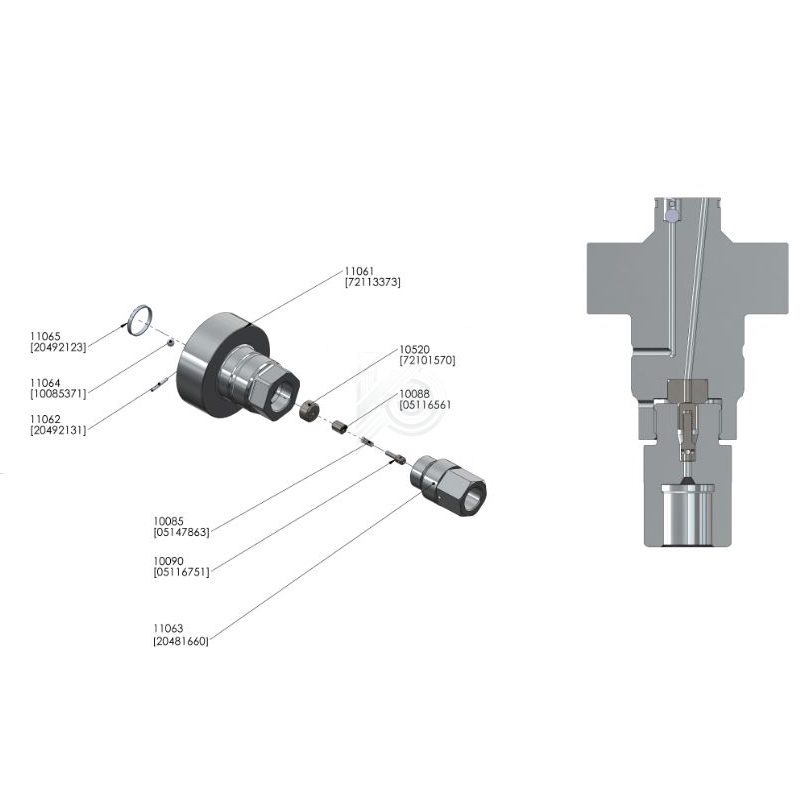

Part Number: KMT 05116561; WSI SL05116561Other References: KMT 05112776; Accustream 1‑11265; H₂O 102007‑1

Barton Code: WK000298

Type: Flat outlet discharge poppet check valve

Plunger Compatibility: .875″ (22.2 mm) intensifier plungers

Pressure Rating: 60,000 psi (4,100 bar) HP; 90,000 psi (6,200 bar) UHP

Material: High‑grade stainless steel

Sealing Face: Neoline‑grade precision ground

Weight: ~0.008 lbs (5 g)

INQUIRY