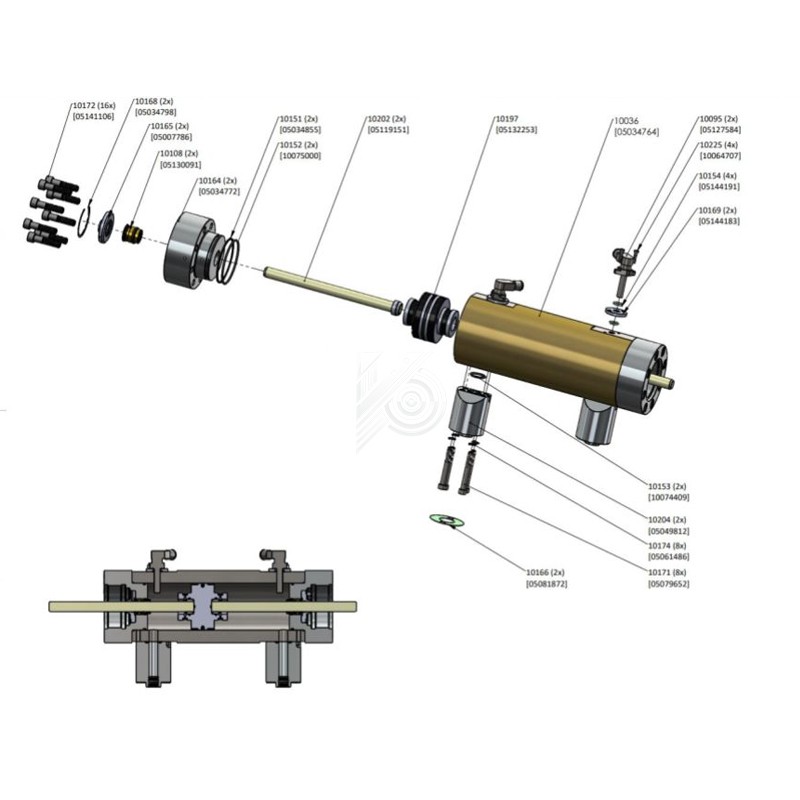

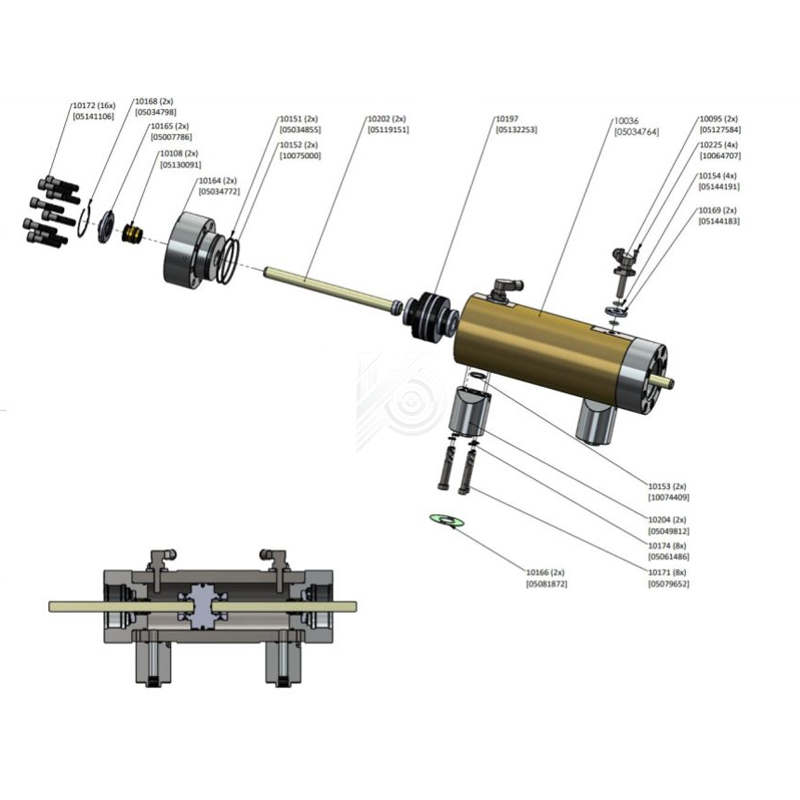

SLV Classic Hydraulic Cartridge Seal Assembly 80086622 Good Quality Water Jet Parts

SLV Classic Hydraulic Cartridge Seal Assembly 80086622 Good Quality Water Jet Parts

KMT Part Number:80086622

WSI Part Number:SF80086622

Alternate Refs:1‑13261, 5000213

Plunger Diameter:0.875 in (22.2 mm)

Pressure Rating:Up to 60 000 psi (4 137 bar)

Weight:0.132 lbs (≈60 g)

Material:Stainless steel canister; high‑grade polymer/elastomer seals