LP Check Valve Poppet SP-73-2 Waterjet Pump Parts In Stock

LP Check Valve Poppet SP-73-2 WaterJet Pump Parts In Stock

Specifications

Material:Hardened stainless steel poppet (proprietary alloy)

Pressure Stage:Low-pressure check (intensifier return stroke)

Operating Pressure:Up to ~5–10 ksi (LP stage of dual-stage intensifier)

Compatibility:Techni Gen 2 and Gen 4 intensifier pumps (all models)

Weight:~0.02 kg (approximate)

Installation & Maintenance

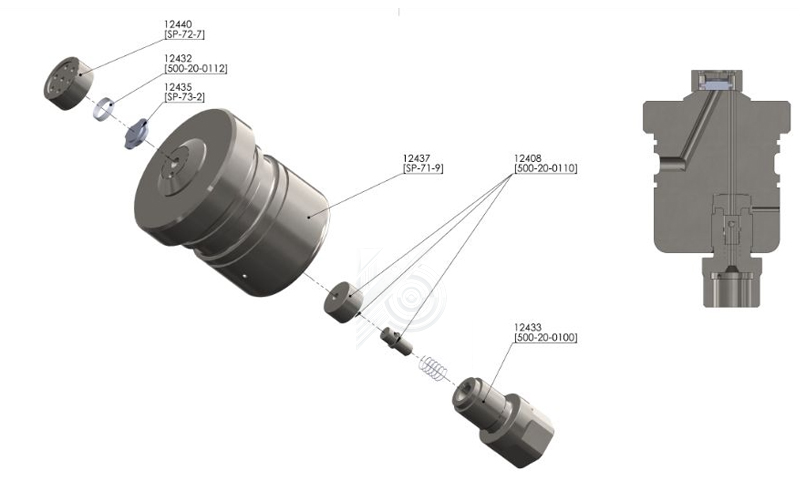

Depressurize & Drain: Fully isolate the pump and relieve hydraulic pressure.

Access Valve Housing: Remove the intensifier end plate to expose the LP check valve housing (SP-72-7)

Disassemble Housing: Extract the LP spring (500-12-0040) and gently press out the old poppet (SP-73-2) from the housing bore

Inspect & Clean: Clean the housing and spring seat. Inspect bore for scoring; polish or replace if out of tolerance.

Install New Poppet: Place the new SP-73-2 poppet into the housing, reinsert the LP spring, and reassemble per torque specifications.

Test Operation: Repressurize the system at low pressure, cycle the intensifier, and verify one-way flow; then ramp to full pressure and check for leaks.

Material:Hardened stainless steel poppet (proprietary alloy)

Pressure Stage:Low-pressure check (intensifier return stroke)

Operating Pressure:Up to ~5–10 ksi (LP stage of dual-stage intensifier)

Compatibility:Techni Gen 2 and Gen 4 intensifier pumps (all models)

Weight:~0.02 kg (approximate)

Installation & Maintenance

Depressurize & Drain: Fully isolate the pump and relieve hydraulic pressure.

Access Valve Housing: Remove the intensifier end plate to expose the LP check valve housing (SP-72-7)

Disassemble Housing: Extract the LP spring (500-12-0040) and gently press out the old poppet (SP-73-2) from the housing bore

Inspect & Clean: Clean the housing and spring seat. Inspect bore for scoring; polish or replace if out of tolerance.

Install New Poppet: Place the new SP-73-2 poppet into the housing, reinsert the LP spring, and reassemble per torque specifications.

Test Operation: Repressurize the system at low pressure, cycle the intensifier, and verify one-way flow; then ramp to full pressure and check for leaks.