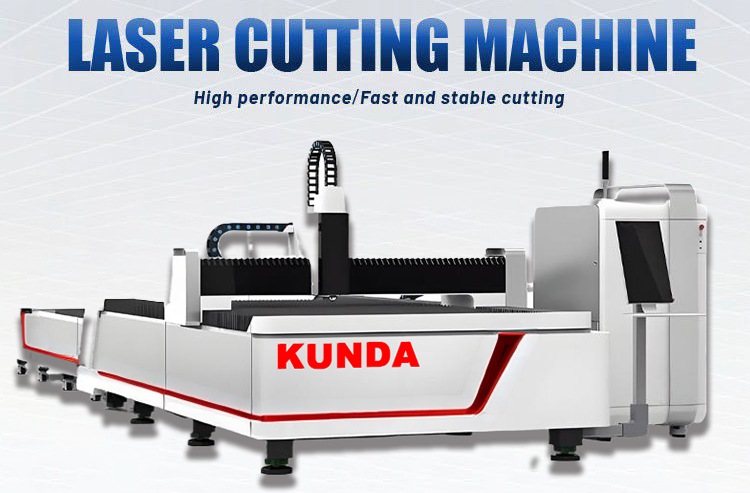

Co2 Laser Cutting Machine Hand Laser Cutting Machine Miniature Laser Cutter

Co2 Laser Cutting Machine Hand Laser Cutting Machine Miniature Laser Cutter

Co2 Laser Cutting Machine is a state-of-the-art solution designed for precision, efficiency, and reliability in metal fabrication. Powered by advanced fiber laser technology, this machine offers unmatched cutting speed and accuracy, making it ideal for a wide range of industries, including automotive, aerospace, electronics, and metalworking.

Model

KD-1530

Working Size

1500*3000MM

X-axis travel

1500MM

Y-axis travel

3000MM

Z-axis travel

120MM

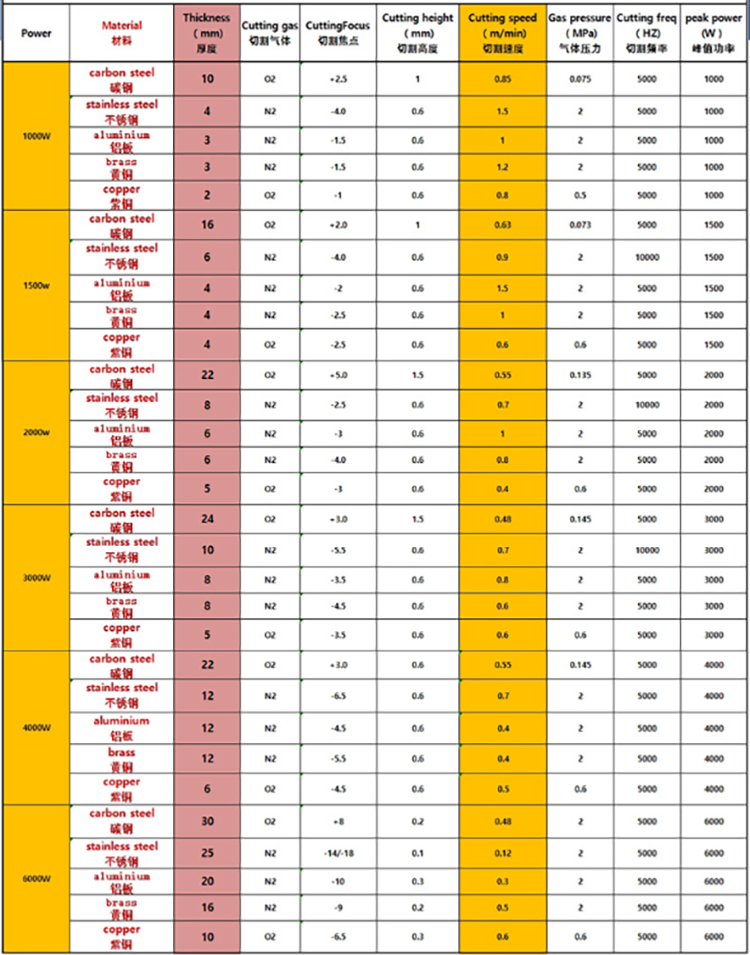

Power

3000W

X, Y axis positioning accuracy

±0.03mm

X, Y axis repeat positioning accuracy

±0.03mm

Maximum moving speed

120m/min

Maximum cutting speed

60m/min

Maximum acceleration

1.0G

Total Power

25KW

Laser wavelength

1064nm

Cutting speed

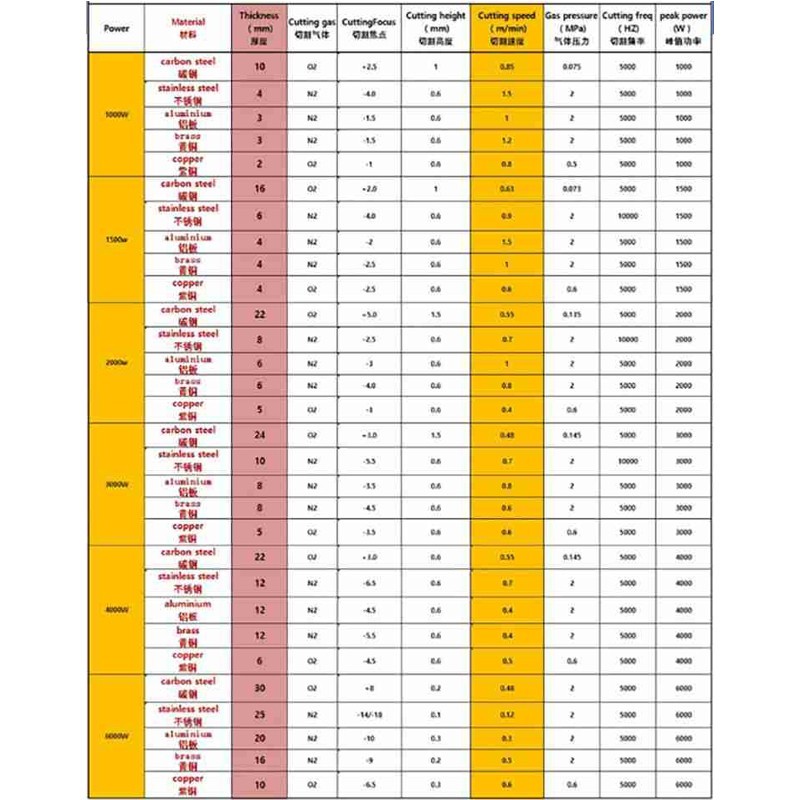

Depends on the material

Auxiliary gas

Air, oxygen, nitrogen

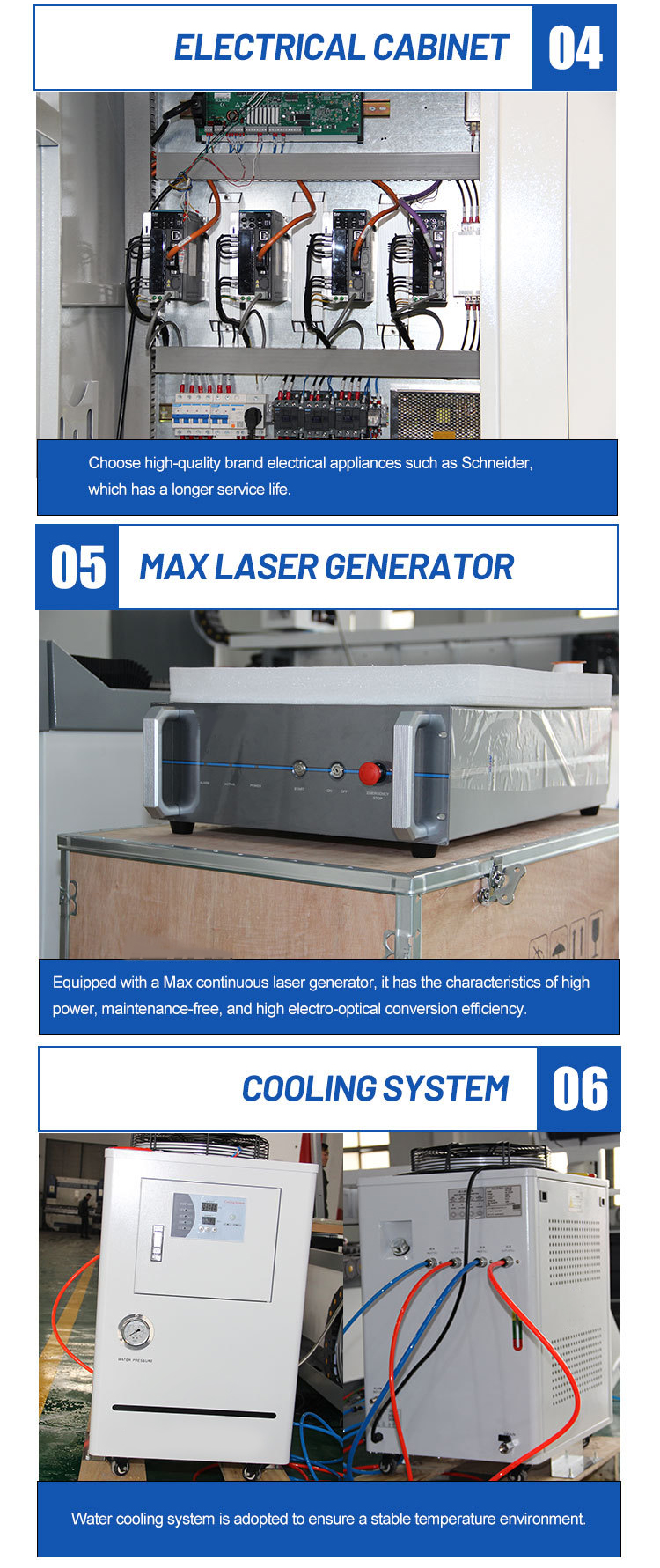

Cooling method

Industrial circulating cooling water

Aiming and positioning

Red light

Working hours

24H

Machine weight

3000KG

Operating temperature

0-45℃

Working environment humidity

10%-85%

The Co2 Laser Cutting Machine generates a high-power density laser beam through a laser, which is focused and irradiated on the surface of the material, causing the material to melt, vaporize or reach the ignition point instantly. At the same time, the coaxial high-pressure gas (such as oxygen and nitrogen) blows the molten material away from the cutting area to form a slit. This non-contact processing method avoids deformation caused by mechanical stress, and the cutting accuracy can reach ±0.02mm. The relative movement of the beam and the material is controlled by the CNC system, and any plane figure can be cut.

Working principle

The Co2 Laser Cutting Machine generates a high-power density laser beam through a laser, which is focused and irradiated on the surface of the material, causing the material to melt, vaporize or reach the ignition point instantly. At the same time, the coaxial high-pressure gas (such as oxygen and nitrogen) blows the molten material away from the cutting area to form a slit. This non-contact processing method avoids deformation caused by mechanical stress, and the cutting accuracy can reach ±0.02mm. The relative movement of the beam and the material is controlled by the CNC system, and any plane figure can be cut.

Core advantages

High precision and quality: The Co2 Laser Cutting Machine cutting width is only 0.1–0.3mm, the incision is smooth and burr-free, and no secondary processing is required.

High efficiency: The Co2 Laser Cutting Machine speed is much faster than traditional processes (such as flame/plasma cutting), and the thin plate cutting speed reaches several meters per minute.

Flexibility: Supports any graphic design, CNC programming realizes automatic typesetting, and saves materials.

Environmental protection and energy saving: No tool loss, energy consumption is lower than traditional mechanical cutting, and dust pollution is reduced.