CNC Waterjet Ceramic Rod Replacement Precision Ground Waterjet Ceramic Plunger Rod

CNC Waterjet Ceramic Rod Replacement Precision Ground Waterjet Ceramic Plunger Rod

CNC Waterjet Ceramic Rod is a core, wear-resistant component installed in a waterjet high-pressure pump or intensifier. It primarily converts hydraulic energy into ultra-high-pressure water energy. It is an essential component of a waterJet Pump. High-quality waterjet ceramic rods can ensure more stable machine operation, reduce pump failure rates, and improve Waterjet Machine efficiency.

In Waterjet Cutting Equipment, hydraulic oil propels the ceramic rod back and forth, compressing low-pressure water into a high-pressure stream (typically 55,000–90,000 psi). This high-speed water jet is then generated by the cutting head and used to cut materials such as glass, metal, and stone.

|

Parameter |

Typical Range/Value |

Description |

|

Material |

Al₂O₃, ZrO₂, Si₃N₄, SiC |

Different materials have different properties |

|

Density |

5.9–6.05 g/cm³ |

depending on material type |

|

Hardness |

15–19 GPa / Mohs 8–9 |

Extremely high wear resistance |

|

Compressive strength |

1500–4000 MPa |

Withstands high-pressure water jet applications |

|

Flexural strength |

~1200 MPa (ZrO₂) |

Resists mechanical shock |

|

Fracture toughness |

~10 MPa·m¹ᐟ² (ZrO₂) |

Resists cracking |

|

Coefficient of thermal expansion |

7–10.5 × 10⁻⁶/K |

Excellent thermal stability |

|

Surface roughness |

Ra 0.05–0.2 μm |

Improves sealing and life |

|

Dimensional tolerance & accuracy |

0.001 mm (accuracy); tolerance: 0.01–0.002 mm |

Precision matching with pump cylinders |

|

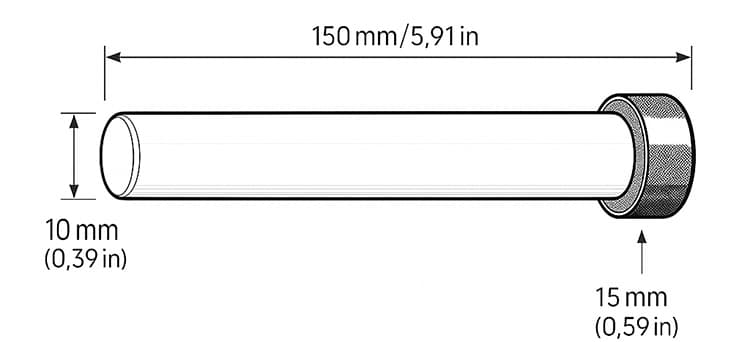

Connector Size Range |

6.35–312.5 mm diameter; 10–200 mm length |

customizable |

|

Working Pressure |

55,000–90,000 psi (UHP capable) |

Suitable for large/ultra-high pressure Waterjet Cutting Systems |

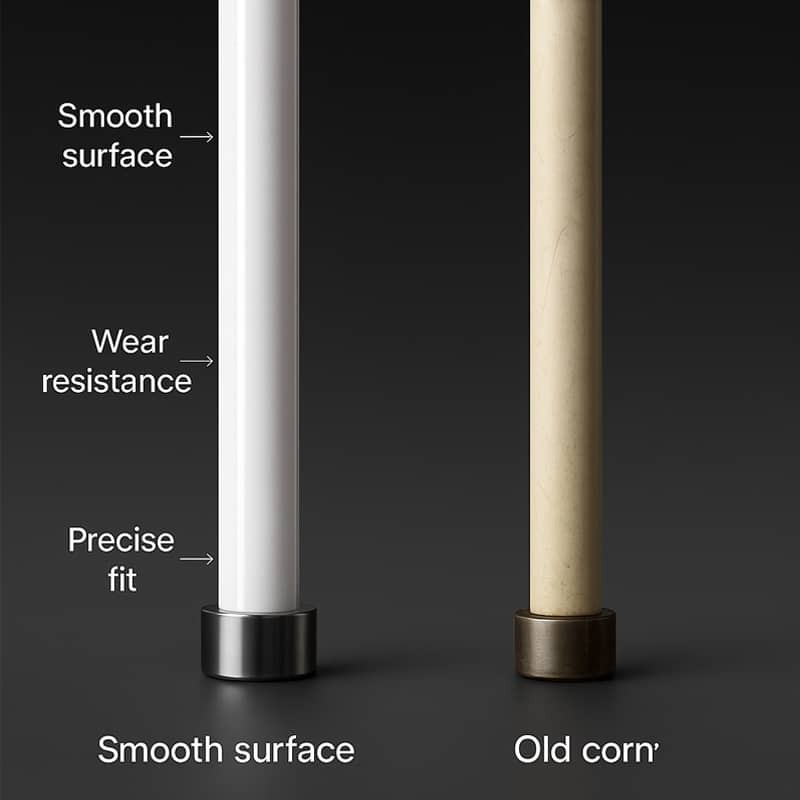

Features and Benefits of CNC Waterjet Ceramic Rod:

- High Hardness & Strength: Made of precision ceramics such as zirconium oxide and aluminum oxide, it achieves a hardness of 8–9 on the Mohs scale.

- Wear-Resistant & Long Service Life: The ceramic surface is smooth, minimizing friction and reducing seal wear.

- High-Precision Machining: Dimensional tolerances are controlled to within 0.01 mm, ensuring a tight seal and stable operation.

- High-Pressure & High-Temperature Resistance: It can operate stably in environments with a compression strength of 4000 MPa and ultra-high pressures of 55,000–90,000 psi.

- Widely Compatible: High-pressure pumps from nearly all major waterjet cutting brands (such as FLOW, KMT, OMAX, and KUNDA) are equipped with ceramic rods.

INQUIRY