A-11080 Abrasive Inlet Cap Flow Waterjet Parts Price

A-11080 Abrasive Inlet Cap Waterjet-Cutting-Machine-Lifting-Jet-Machine-Price-Waterjet-Services-Near-Me-p.html target='_blank'>Flow Waterjet Parts Price

|

Part |

Replaces |

Name |

|

1-12747 |

|

DiaLine Carbide Mixing Chamber- Single Inlet Cutting Heads |

|

1-14465 |

711933-1 |

Blast Disc |

|

1-14468 |

041138-1 |

Mixing Chamber, PASER4 |

|

1-14464 |

711589-1 |

Knurled Nut, New Style, PASER4 |

|

1-14495 |

A-11080 |

Abrasive Inlet Cap |

|

1-14466 |

A-23161-8 |

Precision Collet, PASER 4 |

|

1-14467 |

712265-1 |

Mixing Tube Spacer, PASER® 4 |

|

1-14463 |

041137-1 |

PASER 4 Nozzle Body, 4.330 in. |

|

1-18741 |

041136-1 |

Dialine4 Cutting Head Assembly for Paser®4 |

|

1-17526 |

044837-1 |

Nozzle Body Adapter - XD Cutting Head |

|

1-14469 |

A-22752-11 |

V-ring Seal, PASER 4 |

|

1-14525 |

041136-1 |

Cutting Head Assembly, PASER 4 |

|

1-17527 |

044866-1 |

90° On/off Valve Adapter |

|

1-13431 |

019519-1 |

87K Nozzle Body, 4.00 in. |

|

1-17530 |

710869-1 |

Nozzle Body Collar |

|

1-17529 |

710867-1 |

Retainer Collar On/off Valve |

|

1-19158 |

045160-2 |

XD Cutting Head Assembly |

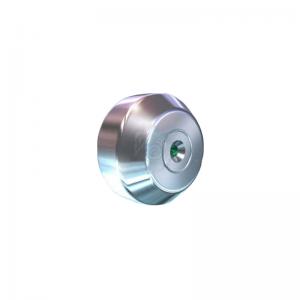

The A-11080 Abrasive Inlet Cap is a top-quality component designed to manage the precise flow of abrasive materials in high-performance cutting and blasting systems. Engineered for durability, this inlet cap effectively channels abrasive media into the cutting head, ensuring smooth, consistent material flow and optimal cutting precision. Constructed from wear-resistant, corrosion-proof materials, the A-11080 Abrasive Inlet Cap is built to withstand the harsh demands of abrasive environments, making it ideal for industries such as waterjet cutting, sandblasting, and surface treatment.

This component is essential for applications requiring high-precision abrasive flow control, ensuring that the cutting head remains unclogged and free from material buildup. By maintaining a stable flow, the A-11080 Inlet Cap optimizes system efficiency, reduces wear on internal components, and minimizes downtime due to maintenance.

Key Features of the A-11080 Abrasive Inlet Cap:

- Controlled Abrasive Flow: The A-11080 Abrasive Inlet Cap is designed to regulate abrasive media flow efficiently, ensuring consistent material delivery to the cutting head for smooth, accurate cuts.

- Durable, Wear-Resistant Construction: Made from high-strength, corrosion-resistant materials, this inlet cap endures abrasive wear and harsh environmental conditions, providing long-lasting performance.

- Reduced Downtime: By preventing clogs and ensuring a steady flow, the inlet cap minimizes maintenance needs, enhancing system uptime and operational efficiency.

- Optimized Cutting Performance: The controlled flow achieved with this inlet cap enhances cutting precision, helping reduce material waste and improve quality in each operation.

- Versatile Applications: Suitable for use in a range of abrasive cutting and blasting systems, including waterjet and sandblasting equipment, this cap is adaptable to multiple industrial needs.

The A-11080 Abrasive Inlet Cap is a reliable and robust solution for optimizing abrasive flow and enhancing system performance. Whether you're upgrading your cutting system or building a new setup, this inlet cap provides durability and efficiency to keep operations running smoothly.

Order the A-11080 Abrasive Inlet Cap today to improve flow control, reduce wear, and maximize the precision of your abrasive system.

If you need other Flow Waterjet Parts,Please contact us!