Industry-news

What is the Function of the 5-Axis Cutting Head in a Water Jet Cutting Machine?

What is the Function of the 5-Axis Cutting Head in A Water Jet Cutting Machine?

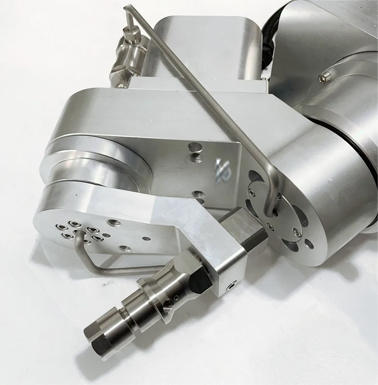

The 5-axis cutting head has revolutionized Water Jet Cutting Technology by enhancing the precision, versatility, and efficiency of the cutting process. This advanced cutting head allows for complex cuts and detailed angles, making it an essential component in industries requiring intricate and accurate material shaping. In this article, we will explore the function and applications of the 5-axis cutting head, with a special focus on Kunda’s high-performance 5-axis cutting heads, known for their reliability and precision in cutting applications.

What is a 5-Axis Cutting Head?

A 5-axis cutting head in a Water Jet Cutting Machine is a component that allows for motion along five different axes: X, Y, Z, A, and C. While a standard 2-axis cutting head moves only in X (horizontal) and Y (vertical) directions, a 5-axis head can tilt and rotate, providing additional angles (A and C axes) and vertical motion (Z axis). This expanded range of motion enables the water jet to cut materials at precise angles and with complex geometries.

The Function of the 5-Axis Cutting Head

The primary function of the 5-axis cutting head is to enable intricate, angled, and complex cuts that are difficult to achieve with standard 2-axis Water Jet Systems. Here’s how it works:

-

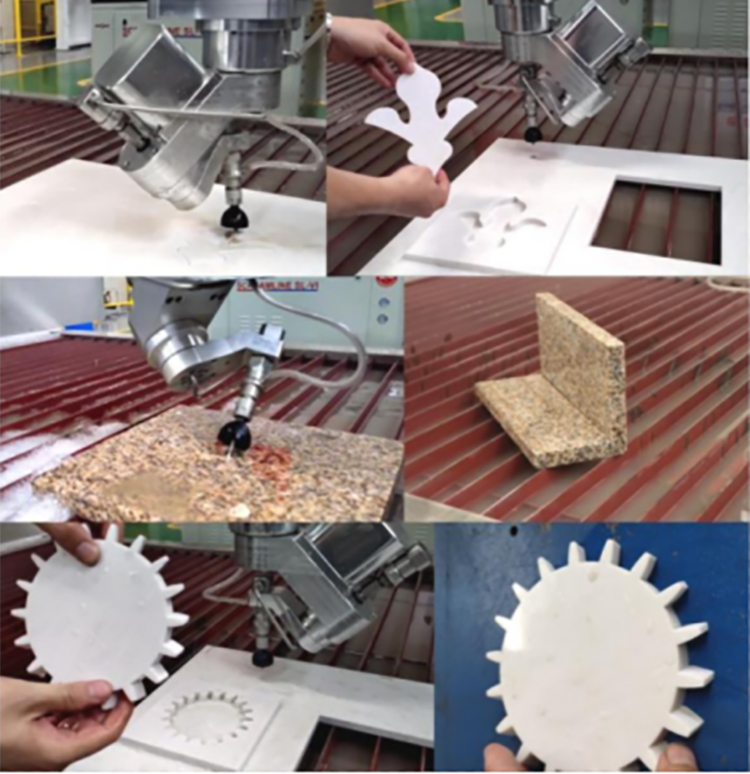

Multi-Directional Motion: The 5-axis head allows the water jet to tilt and rotate, adjusting the angle of the water stream. This capability enables the head to cut beveled edges, countersinks, and other complex shapes.

-

Angle Adjustment: With the ability to adjust angles up to 60° or more, the 5-axis cutting head can easily cut through thick materials and create parts with precise geometric dimensions.

-

High Precision: The advanced movement of the 5-axis cutting head provides exceptional accuracy, reducing the margin of error and minimizing waste. This precision is critical for industries like aerospace, automotive, and architecture, where quality and detail are essential.

-

Reduced Taper: The 5-axis head can adjust the angle of the water jet to eliminate taper, a common issue in water jet cutting where the bottom of the cut is narrower than the top. By compensating for this, the 5-axis cutting head delivers smooth, straight edges, which is particularly beneficial in applications where exactness is required.

Kunda’s 5-Axis Cutting Head: Superior Precision and Reliability

Kunda’s 5-axis cutting heads are designed to provide maximum versatility and reliability for a wide range of cutting applications. Here are some of the key advantages of using Kunda’s 5-axis cutting head in your water jet cutting machine:

-

Exceptional Precision: Kunda’s 5-axis cutting head delivers unmatched precision, allowing for detailed cuts on complex shapes and materials. The head's advanced design reduces the need for secondary finishing processes, saving both time and resources.

-

Ease of Use: Despite its advanced capabilities, Kunda’s 5-axis cutting head is user-friendly, allowing operators to quickly and easily adjust settings for different materials and cutting angles. The intuitive design makes it simple to set up and control, ensuring smooth operation and high efficiency.

-

Durability and Stability: Built with high-quality materials and precision engineering, Kunda’s 5-axis cutting heads are known for their stability and long service life. This durability ensures consistent performance, reducing maintenance costs and maximizing uptime for your operations.

-

Versatile Applications: Whether you are cutting metal, glass, stone, or composite materials, Kunda’s 5-axis cutting head can handle a wide range of applications with ease. Its flexibility and accuracy make it an ideal choice for industries that require versatility, such as aerospace, automotive, construction, and art.

Benefits of Using a 5-Axis Cutting Head

The 5-axis cutting head offers numerous benefits for businesses looking to enhance their cutting processes. Here’s why investing in a 5-axis head, especially from Kunda, can be a valuable choice:

-

Enhanced Flexibility: The ability to cut at different angles and depths means you can achieve intricate shapes and details that are not possible with a standard cutting head.

-

Improved Productivity: With Kunda’s user-friendly design and reliable performance, the 5-axis cutting head boosts productivity by reducing setup times and minimizing errors.

-

Cost Savings: High precision reduces waste and eliminates the need for secondary finishing processes. Kunda’s durable construction also leads to lower maintenance costs and fewer part replacements, contributing to significant long-term savings.

-

Reduced Tapering for Higher Quality Cuts: With the 5-axis cutting head’s angle adjustment capability, tapering can be minimized, delivering clean edges that require little to no further processing.

-

Expanded Application Possibilities: The 5-axis head’s ability to handle complex cuts makes it ideal for specialized applications, enabling businesses to expand their service offerings.

How to Operate a 5-Axis Cutting Head

Operating Kunda’s 5-axis cutting head is straightforward, thanks to its user-friendly design:

-

Setup: Mount the 5-axis head onto the water jet cutting machine and ensure it is securely in place. Make the necessary adjustments based on the material and cutting angle required.

-

Select Cutting Parameters: Adjust the settings on the control panel to specify the desired angle, pressure, and cutting speed for the material.

-

Monitor Operation: Once cutting begins, monitor the process for accuracy and consistency. Kunda’s 5-axis cutting head maintains stable performance, reducing the need for frequent adjustments.

-

Adjust as Necessary: If the material or project specifications require changes, the head can be easily adjusted mid-operation without significant downtime.

Conclusion

The 5-axis cutting head is a transformative addition to any water jet cutting machine, allowing for precise, intricate cuts that meet the demands of modern industries. Kunda’s 5-axis cutting heads stand out for their accuracy, stability, and ease of use, providing businesses with an efficient, cost-effective solution for complex cutting applications. By investing in a Kunda 5-axis cutting head, you gain access to advanced cutting technology that enhances productivity, minimizes waste, and opens up new possibilities for high-quality, detailed cuts.

If you’re in the market for a reliable, high-performance 5-axis cutting head, look no further than Kunda. With Kunda’s innovative design and robust build quality, you can count on a cutting head that delivers consistent results and lasting value.