Industry-news

What is the Function of a Waterjet Intensifier Pump? How to Operate It?

What is the Function of a Waterjet Intensifier Pump? How to Operate It?

Rated Power

30KW/40HP

Max. operating pressure

420MPa/4137bar/60000psi

Continuous working pressure

320MPa-380MPa

Max. discharging rate

3.8L/min

Orifice diameter

0.33mm or others

Nozzle diameter

1.02mm or others

Tank volume

150L

Size

1800mm*1100mm*1300mm

Weight

1.3t

Waterjet cutting technology has become an essential part of various industries, thanks to its precision, versatility, and ability to cut through a wide range of materials. At the heart of this technology lies the waterjet intensifier pump. But what exactly is a waterjet intensifier pump, and how does it operate? In this article, we will explore the function of this critical component, explain its operation, and highlight the benefits of using Kunda's intensifier pumps, known for their ease of use, stable pressure, and long-lasting performance.

Rated Power

30KW/40HP

Max. operating pressure

420MPa/4137bar/60000psi

Continuous working pressure

320MPa-380MPa

Max. discharging rate

3.8L/min

Orifice diameter

0.33mm or others

Nozzle diameter

1.02mm or others

Tank volume

150L

Size

1800mm*1100mm*1300mm

Weight

1.3t

What is a Waterjet Intensifier Pump?

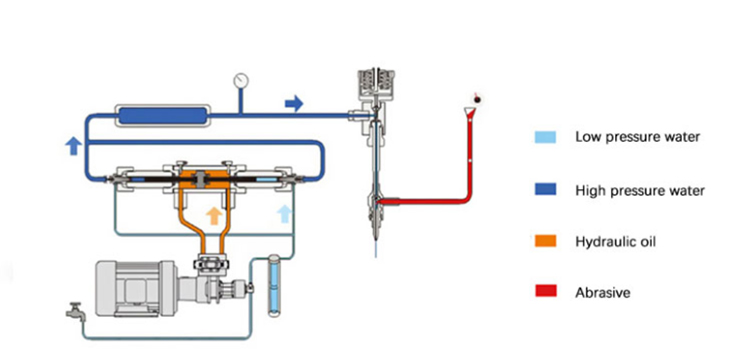

A waterjet intensifier pump is a high-pressure pump used to increase the pressure of water to extreme levels, typically up to 60,000 psi (pounds per square inch). This high-pressure water is then used to cut, shape, or clean materials in applications such as manufacturing, aerospace, automotive, and more. The pump works by converting mechanical energy from an electric motor into high-pressure hydraulic energy. This high-pressure water is directed through a small nozzle that can precisely cut materials with minimal heat, reducing the risk of material distortion.

The Function of a Waterjet Intensifier Pump

The primary function of a waterjet intensifier pump is to supply high-pressure water that powers the WaterJet Cutting Machine. Here’s how it works in a typical system:

- Water Intake: Water is drawn into the pump at a low pressure.

- Compression: The pump uses An Intensifier piston to compress the water, increasing its pressure to the desired level.

- High-Pressure Output: The compressed water is then sent to the cutting nozzle, where it is directed at the material with high velocity, allowing for precise cutting or cleaning.

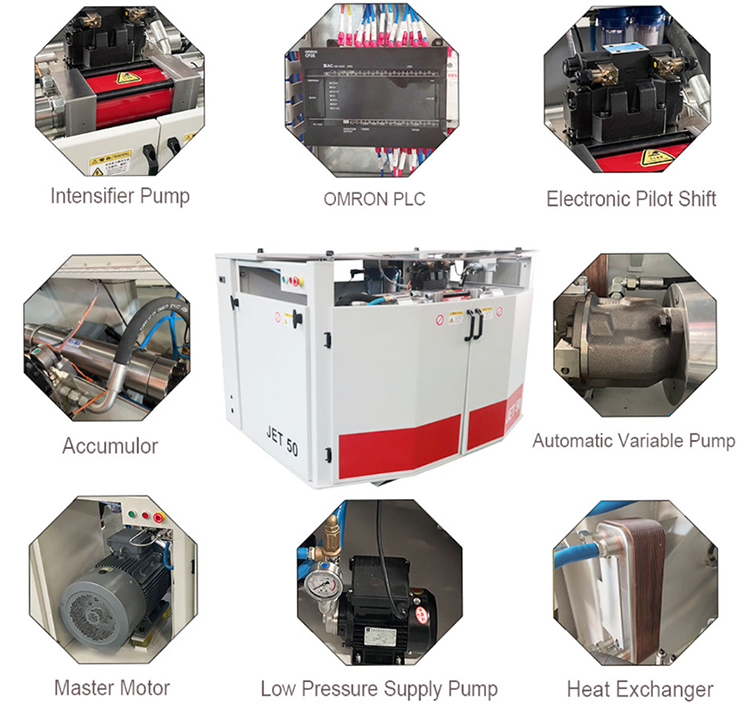

Kunda’s Waterjet Intensifier Pumps: Easy to Operate with Stable Performance

When it comes to waterjet intensifier pumps, Kunda stands out as a leader in providing high-quality pumps that are not only efficient but also reliable. The Kunda waterjet intensifier pump offers several advantages:

-

Easy to Operate: Kunda's waterjet intensifier pumps are designed with user-friendly controls, making them easy to operate. Even those with minimal technical experience can manage these pumps with ease. The intuitive interface ensures smooth operation, minimizing the risk of errors.

-

Stable Pressure: One of the key features of Kunda's pumps is their ability to maintain stable pressure throughout operation. This stability ensures that the cutting process remains consistent, delivering precise results without fluctuation in pressure that could affect the quality of the cuts.

-

Durability and Low Maintenance: Kunda’s pumps are built to last. The high-quality materials used in the construction of each pump help reduce wear and tear, resulting in lower maintenance costs. The components are engineered for longevity, meaning fewer replacements and less downtime.

-

Reliable Performance: Kunda waterjet intensifier pumps are known for their stable and reliable performance over long periods of use. With regular maintenance, these pumps can work continuously, minimizing the need for frequent servicing or part replacements.

Benefits of Using a Waterjet Intensifier Pump

The use of a waterjet intensifier pump in cutting applications offers numerous benefits, including:

- Precision Cutting: The high-pressure water stream ensures clean, sharp cuts with minimal kerf, which is ideal for materials like metals, ceramics, and composites.

- No Heat Affected Zone (HAZ): Since waterjet cutting does not involve heat, there is no risk of thermal distortion, oxidation, or hardening of the material.

- Environmentally Friendly: Waterjet cutting is a "green" process, using water as the cutting medium instead of chemicals or abrasive materials, making it safer for operators and more environmentally sustainable.

How to Operate a Waterjet Intensifier Pump

Operating a waterjet intensifier pump, especially Kunda's models, is a straightforward process:

- Start the Pump: Turn on the pump using the control panel, and ensure that it is connected to a stable water supply.

- Set the Desired Pressure: Select the desired pressure on the control panel, ensuring it matches the requirements of the cutting material and application.

- Monitor the Pump: Once the pump is running, monitor the pressure readings on the display. Kunda's pumps maintain stable pressure, but it's always important to keep an eye on the system to ensure everything is functioning smoothly.

- Adjust for Cutting Needs: Depending on the material being cut, you may need to adjust the cutting speed or nozzle size. Follow the recommended settings for optimal performance.

Conclusion

A waterjet intensifier pump is a critical component for achieving high-precision cutting in various industries. Kunda’s intensifier pumps excel in providing stable pressure, easy operation, and long-term reliability, ensuring that your cutting system runs efficiently and with minimal maintenance. By choosing Kunda, you can count on a waterJet Pump that maximizes performance while minimizing downtime and replacement costs.

Whether you’re cutting metal, stone, or composite materials, Kunda’s waterjet intensifier pumps are an ideal choice for your operations, offering superior performance and lasting value.

If you need our Waterjet Pump,please contact us!