Industry-news

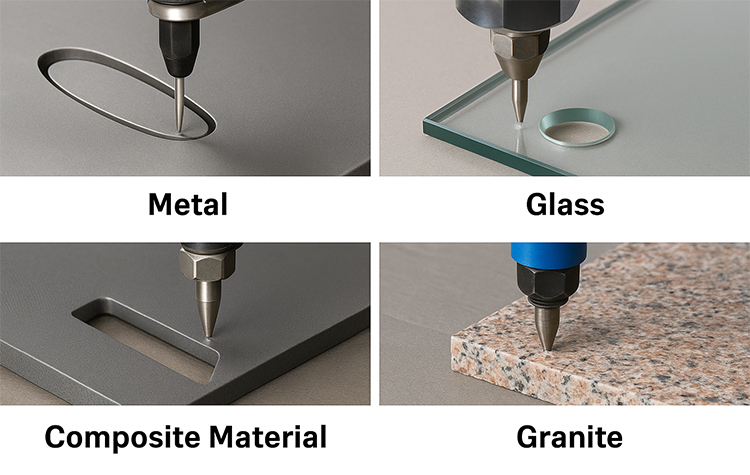

What Materials Could Be Cut By Waterjet Cutting Machine?

What products could be cut by waterjet cutting?

Waterjet cutting (likewise called waterjet cutting or water spray cutting) makes use of ultra-high tension water circulation (with abrasives) to reduce different materials. It ranks of chilly cutting and no heat result, as well as has come to be a "jack of all fields" process in a lot of fields such as sector, development, and stone handling. This write-up will methodically offer the primary components that could be cut through waterjet cutting, highlight its versatility, and help shoppers swiftly comprehend as well as clinically choose.1. Metallics

Carbon steel/ blend steel/ stainless-steel

Density: From 0.1 mm to 300mm, all may be reduced efficiently

Benefits: no heat result, no change in metallic crystal framework, smooth incision

Aluminum metal/ copper/ brass/ titanium composite

Functions: Lightweight metallics or even high-strength steels can be straight processed without thermal contortion

High-temperature composites/ heat-resistant blends

Uses: High-end parts refining in the aerospace and petrochemical industries to keep material residential or commercial properties

Instances of suitable cases: plane components, pipelines for ships, and also vehicle framework layers.

2. Non-metallic and also composite products

Glass/ Ceramics/ Quartz

Perks: Cold weather cutting without splits, cool slices; especially suitable for high-hardness as well as brittle materials

Carbon fiber compounds/ Glass fiber composites

Features: No delamination or even delamination, maintaining the thread design intact

Plastic/ Rubber/ Delicate plastics

Applications: Anti-slip floor coverings, closing bands, water pipes fittings, and so on, no melting and also burrs on the brink

Organic rock/ Artificial stone/ Marbled/ Marble

Benefits: Facility and special-shaped design cutting may be achieved, and the surface area has no edge failure

3. Other unique components

Froth/ Honeycomb light weight aluminum/ Honeycomb paperboard

Delicate cutting, soft edges, no collapse or contortion

Meals/ Frozen chicken/ Fish items

The food items market can be used for hygienic cutting, no pollution

Electronic movie/ PCB panel

Accuracy micro-hole processing, the minimum cutting width can be as reduced as 0.2 mm.

4. The center advantage of water jet cutting flexibility.

Strong material compatibility.

Water jet cutting is not confined by component energy, image, hardness, and so on, as well as there is virtually "no material dead slant".

Cold weather reducing process.

No heat result, no change in the internal construct of the material, and also maintains the initial technical homes.

Higher accuracy and difficulty.

The minimum slit width can easily reach 0.2 mm, effortlessly accomplishing great processing like exclusive designs, interior dental caries, and tiny trends.

Environmental management and also energy conserving.

Simply water and abrasives are used to lessen harmful gas as well as dirt exhausts, in line with environment-friendly production.

Computerization compatibility.

Perfectly incorporated with CNC units, it may quickly achieve automation or even tailored personalization.

5. Chart suggestions

|

Material Type |

Typical thickness range |

Key Benefits |

|

Metal |

0.1–300 mm |

No heat impact, smooth cuts |

|

Glass/ceramics |

1–50 mm |

No cracks, neat edges |

|

Composites |

0.5–100 mm |

No delamination, high precision |

|

Plastics/rubber |

0.1–50 mm |

No melting, no burrs |

|

Natural stone |

5–200 mm |

Special-shaped cutting, high decorativeness |