Waterjet Coil M20-1-2-REV1 For Robot Waterjet Cutting Machine

Waterjet Coil M20-1-2-REV1 For Robot Waterjet Cutting Machine

|

20480158

|

Coil Axis 4,5,6

|

|

M20-1-2-REV1

|

Coil Axis 1,2

|

|

M20-L-1CTREV1

|

Coil Axis 1

|

|

M20-M-2CT

|

Coil Axis 2

|

|

M20-N-3CT

|

Coil Axis 3

|

|

104509

|

Coil Fanuc 1

|

|

104510

|

Coil Axis 2

|

|

104511

|

Coil Fanuc 3

|

|

104521

|

Coil Fanuc 4

|

|

104522

|

Coil Fanuc 3

|

|

104536

|

Coil Fanuc 2

|

|

104537

|

Coil Fanuc 5

|

|

104557

|

Coil Fanuc 1

|

|

104745

|

Coil Fanuc Line 4

|

|

104746

|

Coil Fanuc Line 5

|

|

104780

|

Coil Fanuc 2

|

|

104786

|

Coil Fanuc M20 M4,5,6

|

|

106259

|

Coil Fanuc Line 5

|

|

106260

|

Coil Fanuc Line 4

|

|

107158

|

Coil Fanuc change 104746

|

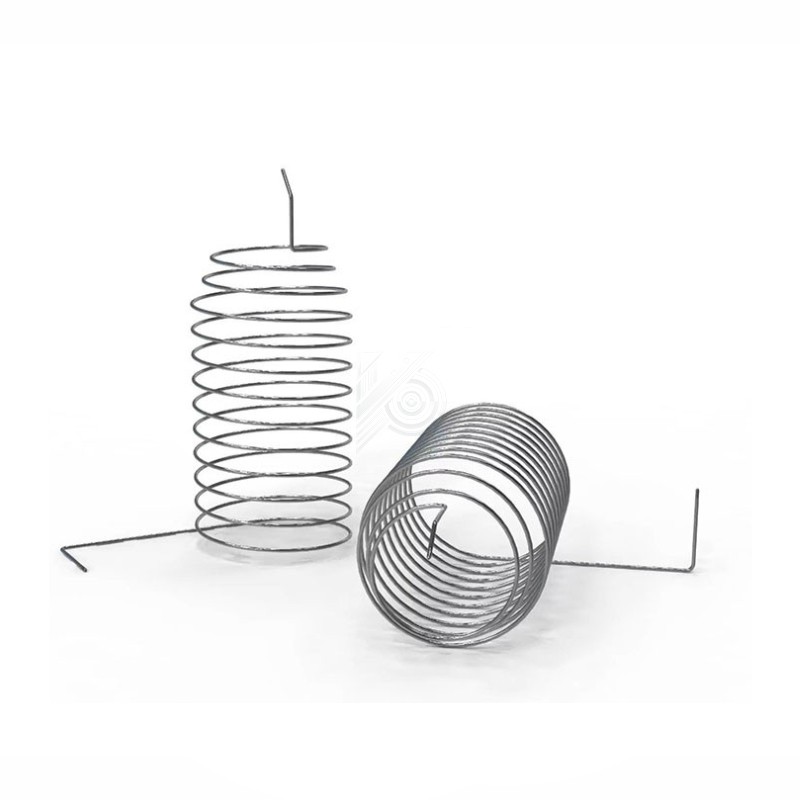

The M20-1-2-REV1 is a high-pressure coiled tube designed for use in FANUC robotic waterjet cutting systems, specifically as an adapter between the 1st and 2nd axes. This coil ensures the efficient and flexible delivery of ultra-high-pressure water from the intensifier pump to the cutting head, accommodating the robot's movements without compromising flow or pressure.

These Waterjet Coil M20-1-2-REV1 are typically made of 316 stainless steel and can withstand pressures up to over 60.000 psi whileremaining corrosion-resistant and flexible.

Regular maintenance Waterjet Coil M20-1-2-REV1--checking for wear, checking for leaks at joints, and veriflying coil integrity-ensures along service life.

Replacement Waterjet Coil M20-1-2-REV1 intervals vary based on usage, but are typically every 1 ,000-2,000 hours of operation or at the firstsign of defommation.