Small Water Jet Cutter For Sale Steel 1015 Abrasive Water Cutting Machines Price

Small Water Jet Cutter For Sale STeel 1015 Abrasive Water Cutting Machines Price

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-2015 5 axis Water Jet |

|

Table Size |

1000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

1000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

30KW/40HP |

|

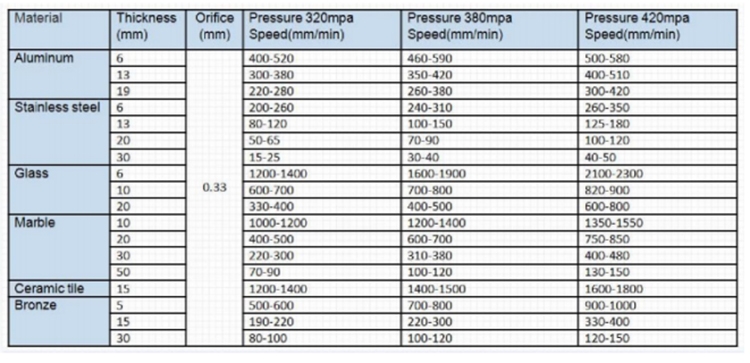

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

3.8L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

150L |

|

Size |

20020mm*1260mm*1310mm |

|

Weight |

1300kg |

The Small Water Jet Cutter is an innovative solution for industries needing precision cutting in a space-saving package. Designed for efficiency, accuracy, and versatility, this compact machine is perfect for workshops, prototyping labs, and production facilities where space and budget constraints require streamlined equipment without compromising performance.

Key Features and Benefits:

-

Compact and Efficient Design: The small footprint of the Small Water Jet Cutter makes it ideal for tight spaces. Its design allows for easy integration into existing workspaces, enabling high-precision cutting capabilities without the need for a large-scale setup.

-

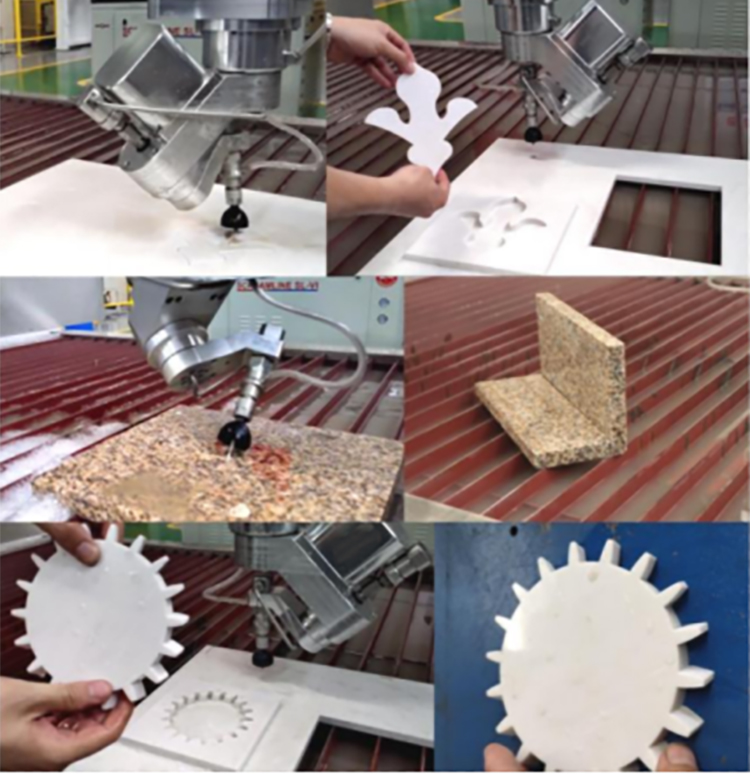

Precision Cutting Capability: Utilizing advanced waterjet technology, the Small Water Jet Cutter offers clean, burr-free cuts on a wide variety of materials, including metals, composites, glass, ceramics, and plastics. The high-pressure jet ensures exact results with minimal material waste.

-

Versatile Applications: Whether used for cutting intricate parts for prototyping, custom designs, or small production runs, this cutter handles diverse applications with ease. It is suitable for industries such as aerospace, automotive, medical device manufacturing, and custom fabrication.

-

Eco-Friendly Cutting Process: The waterjet cutting process does not generate harmful fumes or rely on chemicals, making the Small Water Jet Cutter an environmentally friendly option. The cold-cutting process also avoids heat-affected zones, preserving material integrity and preventing thermal distortion.

-

User-Friendly Operation: Equipped with intuitive controls and software, the Small Water Jet Cutter allows for ease of use, even for operators new to waterjet technology. Its straightforward interface and setup reduce training time, enabling teams to achieve precise cuts quickly.

-

Cost-Effective Solution: With lower operational costs compared to larger waterjet systems, the Small Water Jet Cutter provides an affordable entry point into waterjet cutting technology. Its efficiency in power and water usage ensures that running costs remain manageable while maintaining high performance.

Applications: The Small Water Jet Cutter is perfect for custom fabrication shops, educational institutions, small manufacturers, and prototyping facilities. It meets the needs of industries that require detailed and precise cuts without the scale or expense of industrial-sized machines.

Invest in the Small Water Jet Cutter for precision, reliability, and the versatility needed in modern production environments. Experience high-quality cutting capabilities in a compact and eco-conscious design that boosts productivity and enhances operational efficiency.

Other type of WaterJet Cutting Machine,please contact us!!!