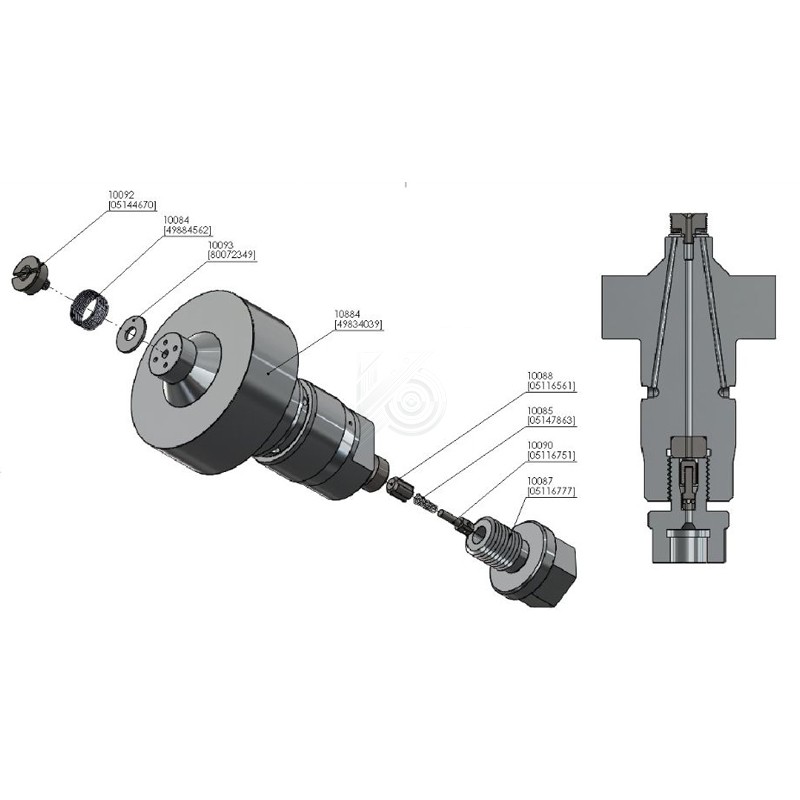

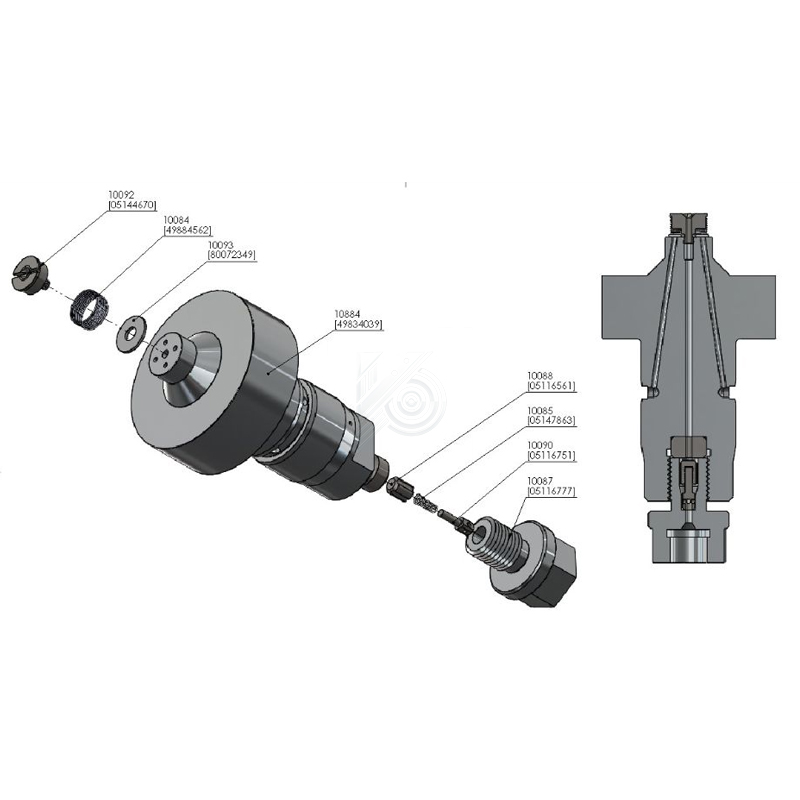

SLV HP Sealing Head Assembly 80072349 Waterjet Parts

SLV Sealing Head Assembly 80072349 Waterjet Parts

KMT Part Number: 80072349

AccuStream Cross‑Reference: 1‑12388

Aqualon Article Number: 10912 (Other refs: 1‑12388, 104024)

Net Weight: 1,382 g (≈3.05 lbs)

Pressure Rating: 60,000 psi (4,100 bar) HP service

Plunger Compatibility: 0.875″ (22.2 mm) intensifier plungers

Configuration: Single‑inlet, flat‑outlet sealing head assembly (old‑style SL‑V)

According to WSI, part SF80072349 (equivalent to KMT 80072349) includes:

1× SF49834039 Sealing Head Body (SL‑V old style)

1× SL05112768 Flat‑Outlet Seat

1× SL05116561 Flat‑Outlet Poppet

1× SP05147863 Flared Compression Spring

1× SL05116751 Poppet Spring Guide

1× SL05116777 Check Valve Adapter (Gland Nut)

1× SP05144662 Inlet Flat‑Outlet Poppet

1× SL49884562 Inlet Poppet Spring

1× SP05144670 Inlet Poppet Retainer