Robot Water Jet Side-mounted Double Hand ABB1600 For Car Interior

Robot Water Jet Side-mounted Double Hand ABB1600 For Car Interior

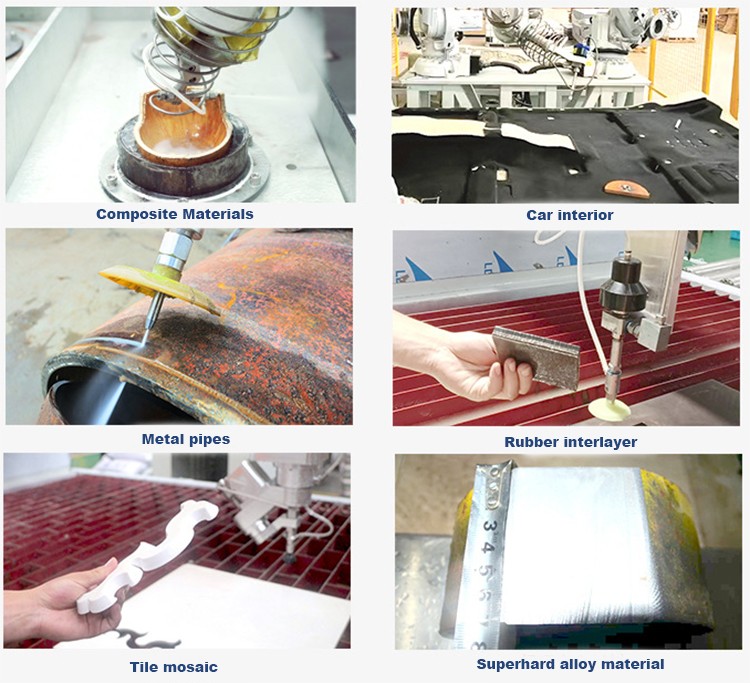

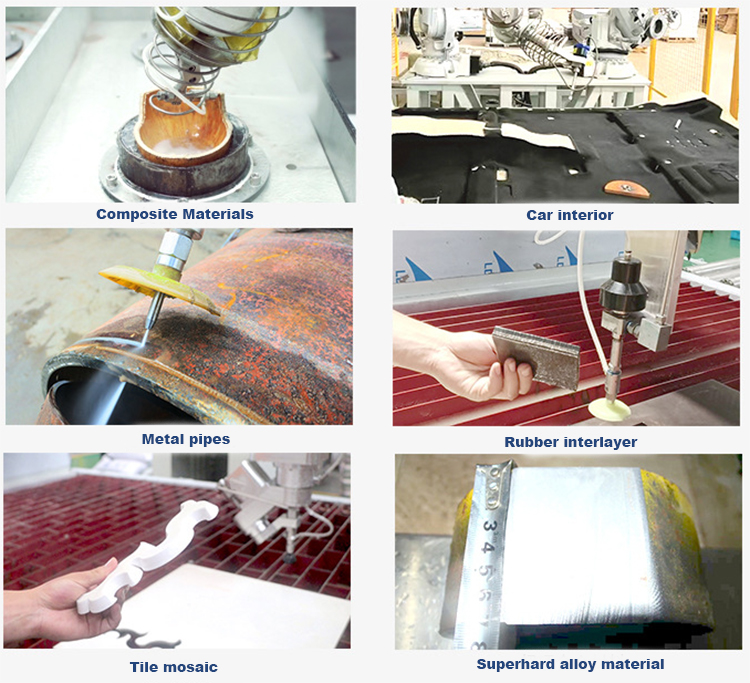

Robotic water jet cutting is specifically used in the following industries:

Industrial manufacturing: Robotic water jet cutting machines can accurately cut various metal and non-metal materials, such as steel, aluminum, etc. In the automotive, aviation and other manufacturing industries, robotic water jet cutting machines are widely used in the cutting of high-precision parts to meet the high requirements for accuracy and operating speed.

Medical technology: With the development of the medical industry, the requirements for equipment accuracy and operating speed are increasing. Robotic water jet cutting machines can accurately remove diseased tissues or tumors without damaging surrounding tissues due to their high precision and low temperature cutting characteristics. They can also be used to make medical devices such as micro-devices or stents.

Military equipment: The military has extremely high requirements for the reliability and accuracy of equipment. In the manufacture of military equipment, robotic water jet cutting machines can cut high-precision, high-quality parts to meet the requirements of military equipment for accuracy and durability.

Automotive interior cutting: Robotic water jet cutting has become the mainstream technology for automotive interior cutting. It can process various automotive interior materials, such as plastics, leather and fabrics, and cut parts of various shapes and sizes through a combination of high-pressure water flow and sand particles, improving cutting accuracy and efficiency while reducing labor costs and waste generation.

Environmental protection industry: Robotic water cutting also plays an important role in some environmental protection applications. For example, when using high-pressure water cutting for fine 3D cutting tasks, it will not produce thermal fatigue and non-toxic smoke, which meets environmental protection requirements.

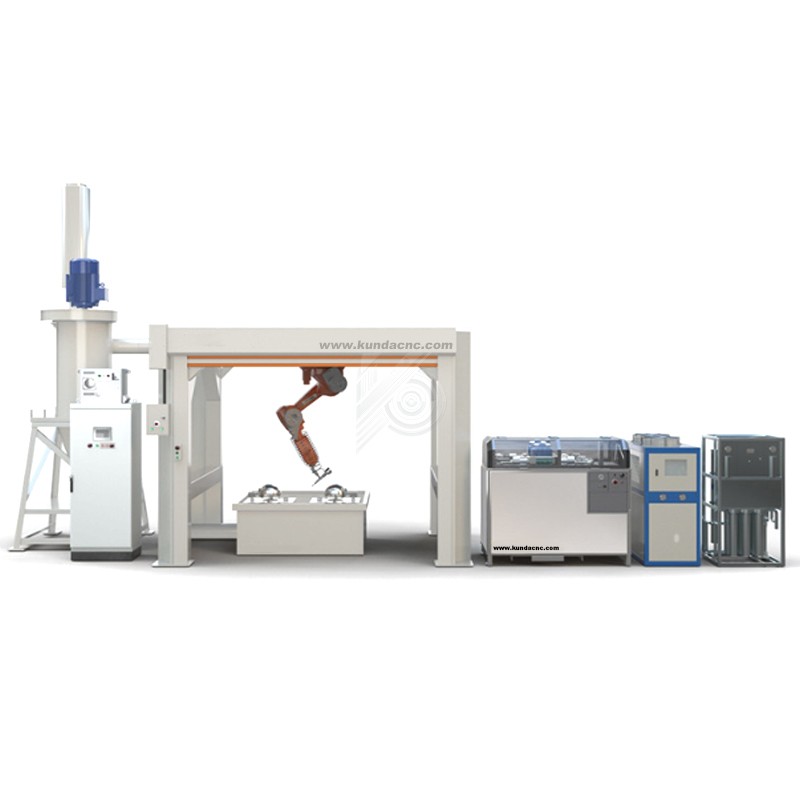

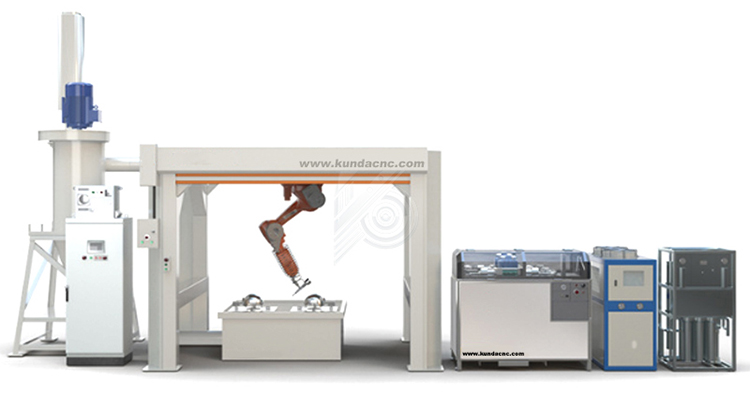

The Robot Water Jet is an advanced robotic system integrated with high-pressure waterjet technology, designed to automate and optimize cutting processes across a wide range of industries. This cutting-edge solution combines the precision of robotics with the power and versatility of waterjet cutting, allowing for highly accurate, efficient, and flexible production capabilities.

The Robot Water Jet is ideal for industries that require complex and intricate cuts, such as aerospace, automotive, metal fabrication, and stone cutting. Equipped with a robotic arm, the system can move in multiple axes, enabling it to reach difficult angles and perform cuts with high precision, even on thick materials. This flexibility reduces the need for multiple machines and operators, streamlining operations and enhancing overall productivity.

The integration of waterjet technology allows the Robot Water Jet to cut through a wide range of materials, including metal, glass, ceramics, plastics, and composites, without causing thermal distortion or material damage. The waterjet's cold cutting process ensures that the material’s integrity is maintained, making it an ideal choice for sensitive materials and complex geometries.

With its automation capabilities, the Robot Water Jet significantly reduces human error and increases cutting speed, leading to faster turnaround times and lower operational costs. Additionally, the system can be programmed to handle multiple tasks, making it highly adaptable to various production needs.

For businesses seeking to improve efficiency, precision, and flexibility, the Robot Water Jet offers a powerful solution that enhances production capabilities and ensures high-quality results in demanding environments.