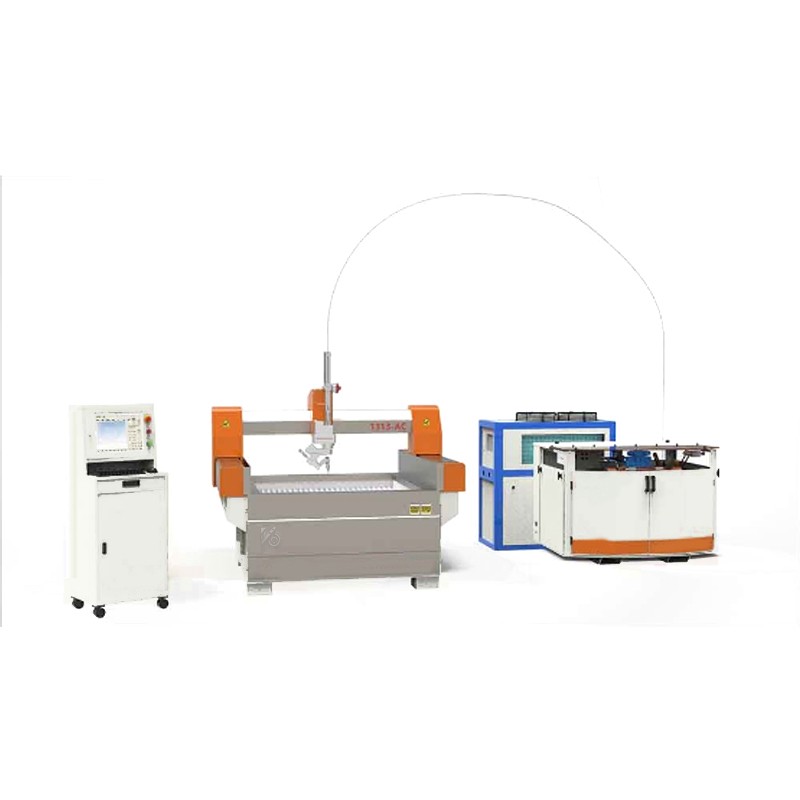

Mini Waterjet Cutter Stainless Steel 3018 Water Jet Abrasive Cutting Machien Supplier

Mini WaterJet Cutter Stainless STeel 3018 Water Jet Abrasive Cutting Machien Supplier

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-2015 5 axis Water Jet |

|

Table Size |

1000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

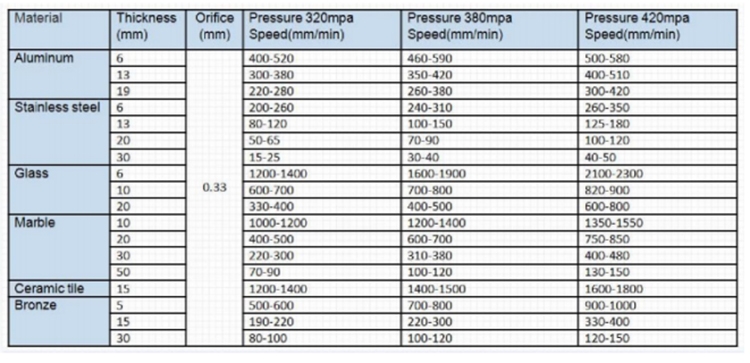

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

1000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

30KW/40HP |

|

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

3.8L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

150L |

|

Size |

20020mm*1260mm*1310mm |

|

Weight |

1300kg |

The Mini Waterjet Cutter is the ideal solution for industries and workshops seeking high-precision cutting capabilities in a compact and efficient design. This advanced cutting tool harnesses the power of waterjet technology to deliver clean, accurate cuts on a variety of materials without heat distortion or chemical processes. Perfect for small-scale operations, prototyping labs, and educational institutions, the Mini Waterjet Cutter provides unparalleled versatility and reliability.

Key Features and Benefits:

-

Compact and Space-Saving Design: The Mini Waterjet Cutter is designed to fit in limited spaces, making it an excellent choice for smaller workshops or production environments. Despite its compact size, it maintains the cutting precision and power of larger waterjet systems, allowing you to maximize your operational capabilities without sacrificing space.

-

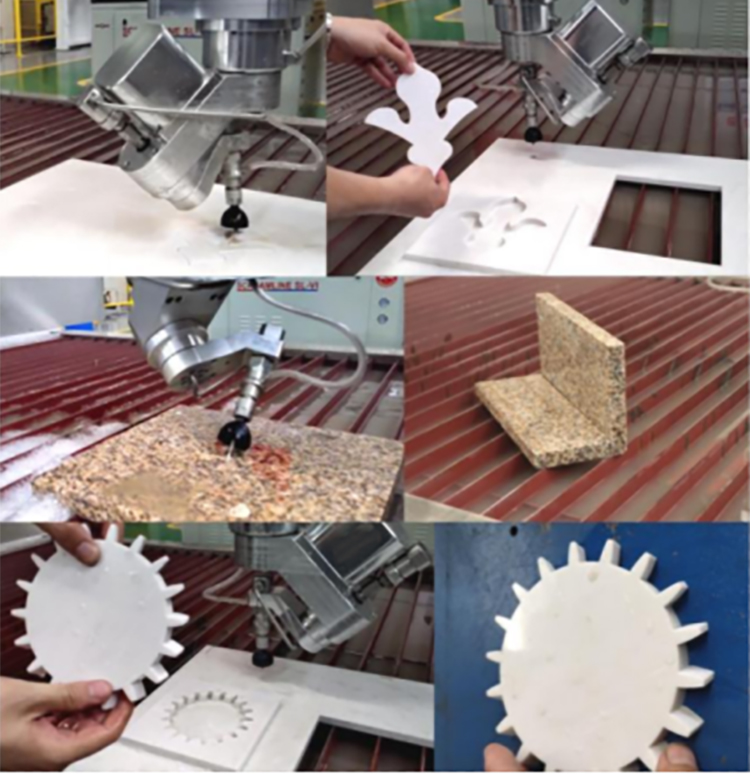

Precise and Versatile Cutting: Capable of cutting through metals, glass, ceramics, plastics, and composites, the Mini Waterjet Cutter is designed for versatility. It delivers smooth, burr-free edges with high accuracy, enabling users to produce detailed and intricate parts ideal for prototypes, custom projects, and smaller production runs.

-

Cold Cutting Process: Unlike traditional cutting methods that produce heat and risk distorting the material, the Mini Waterjet Cutter uses a cold-cutting process. This prevents heat-affected zones, preserving the integrity and properties of the materials and ensuring a high-quality finish.

-

Environmentally Friendly Operation: The waterjet cutting process is inherently eco-friendly, producing no harmful fumes or toxic byproducts. Additionally, water and abrasive materials can be recycled, contributing to a sustainable and low-waste production environment.

-

User-Friendly Interface: The Mini Waterjet Cutter comes equipped with intuitive controls and easy-to-use software that streamline operation, making it accessible even for users new to waterjet technology. Minimal training is required to start cutting with precision, making it perfect for businesses aiming to enhance productivity quickly.

-

Cost-Effective Efficiency: Designed with energy efficiency and minimal resource use in mind, the Mini Waterjet Cutter provides an economical cutting solution. Its low maintenance needs and reduced operational costs make it a smart investment for businesses of all sizes.

Applications: The Mini Waterjet Cutter is well-suited for industries such as automotive, aerospace, education, custom manufacturing, and prototyping. It is an indispensable tool for those needing precise, clean cuts in a smaller package without compromising on performance or versatility.

Choose the Mini Waterjet Cutter for a powerful, compact, and efficient cutting solution that meets modern demands for precision and sustainability in production.

Other type of WaterJet Cutting Machine,please contact us!!!