Mini Water Jet Cutting Machine Marble Abrasive 2010 Waterjet Cutter Machine Supplier

Mini Water Jet Cutting Machine Marble Abrasive 2010 WaterJet Cutter Machine Supplier

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-2015 5 axis Water Jet |

|

Table Size |

1000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

1000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

30KW/40HP |

|

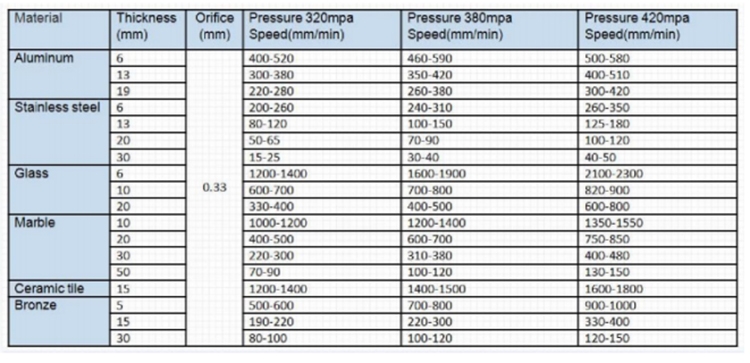

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

3.8L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

150L |

|

Size |

20020mm*1260mm*1310mm |

|

Weight |

1300kg |

The Mini Water Jet Cutting Machine is a top-tier solution for industries and workshops that require precise cutting capabilities in a compact, efficient format. As a powerful tool that integrates the core advantages of waterjet technology, this machine offers high accuracy, versatility, and reliability. It's particularly suited for small-scale production, educational environments, and custom manufacturing projects.

Key Features and Benefits:

-

Space-Efficient Design: With its compact footprint, the Mini Water Jet Cutting Machine is ideal for spaces where room is limited. Despite its smaller size, it boasts impressive cutting power and precision, making it an excellent addition to any workshop or prototyping facility.

-

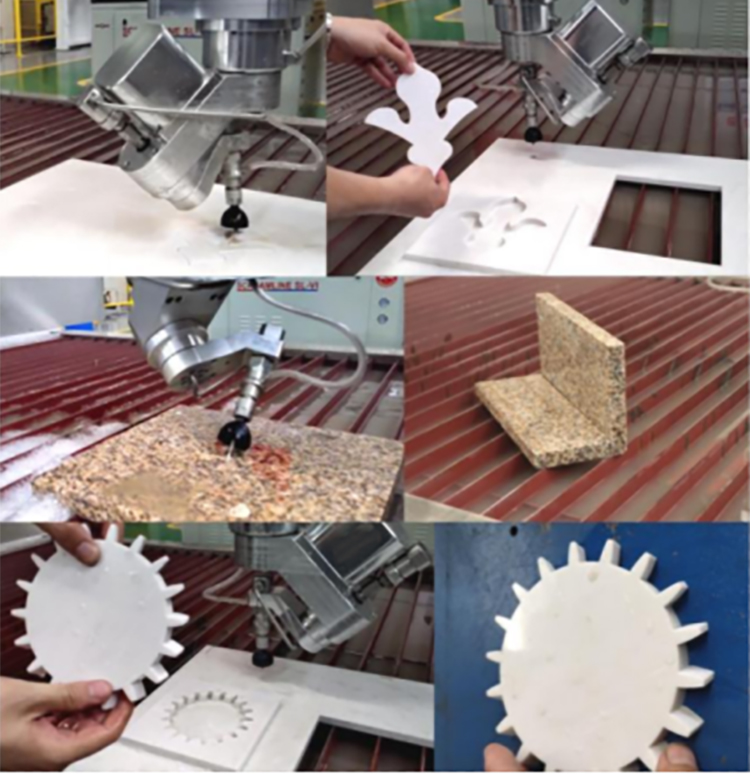

Exceptional Cutting Precision: Capable of handling materials such as metals, ceramics, glass, plastics, and composites, this machine delivers smooth, clean cuts without burrs. Its high-pressure waterjet ensures precise results, perfect for detailed projects and complex designs.

-

Cold Cutting Technology: The Mini Water Jet Cutting Machine uses a cold-cutting process, meaning it doesn’t produce heat during operation. This eliminates the risk of heat-affected zones, maintaining the structural integrity of the material and ensuring a top-quality finish without distortion.

-

Eco-Friendly and Safe Operation: Waterjet cutting is an environmentally friendly process that doesn’t emit harmful gases or involve toxic chemicals. Additionally, the ability to recycle water and abrasives contributes to sustainable use and reduces waste, making it a responsible choice for modern manufacturing.

-

User-Friendly Interface: The machine is equipped with intuitive controls and software that streamline operation, even for users with limited experience in waterjet technology. This feature minimizes the learning curve and allows users to get up to speed quickly, boosting productivity.

-

Cost-Effective Solution: Offering significant cost savings, the Mini Water Jet Cutting Machine is more affordable to operate and maintain compared to larger industrial machines. Its energy-efficient design and reduced water consumption lower running expenses, making it an economical option for businesses of all sizes.

Applications: The Mini Water Jet Cutting Machine is ideal for custom manufacturers, prototyping specialists, educational labs, and artisans who need precise, high-quality cuts. It meets the demands of sectors such as automotive, aerospace, electronics, and creative industries, where precision and flexibility are essential.

Opt for the Mini Water Jet Cutting Machine to experience the power, precision, and adaptability of waterjet technology in a compact, user-friendly format that enhances productivity and reduces costs.

Other type of Waterjet Cutting Machine,please contact us!!!