Specifications

Part Number: 301635

Dimensions: 0.813″ outer diameter × 0.692″ inner diameter

Cross-Section: Standard ring seal profile for static sealing

Material: Gray elastomeric compound designed for high-pressure wear resistance

Weight: ~0.003 lbs (1.36 g)

OEM Reference: Replaces OMAX 301635; 45011; AW301635; F300-D0062-0000; 1-11992

Installation & Maintenance

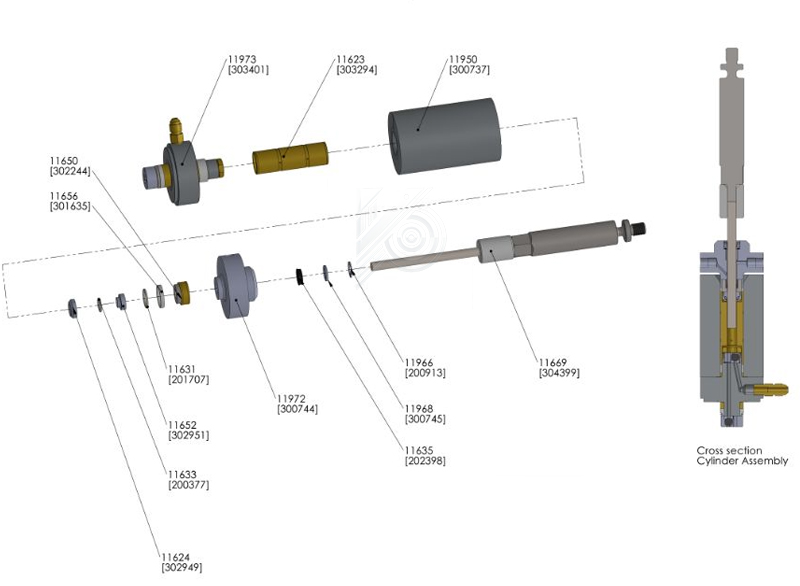

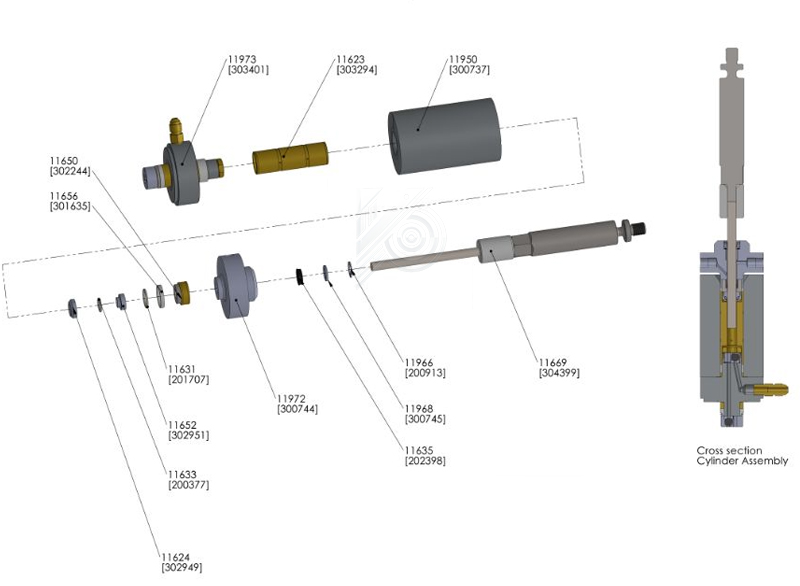

Depressurize & Disassemble: Safely relieve pump pressure; remove cylinder head per OEM manual.

Remove Old Seal: Use a non-marring pick to extract the worn static seal from its gland.

Clean & Inspect: Wipe the gland bore clean; inspect for grooves or damage; polish minor imperfections.

Install New Seal: Lightly lubricate the new 301635 seal with pump oil; press into the gland until fully seated.

Reassemble & Test: Reinstall piston and head, repressurize gradually, and verify zero leakage under no-load conditions.