Intensifier In Water Jet Machining Constant Pressure Intensifier Pump for Glass Cutting Supplier

Intensifier In Water Jet Machining Constant Pressure Intensifier Pump for Glass Cutting Supplier

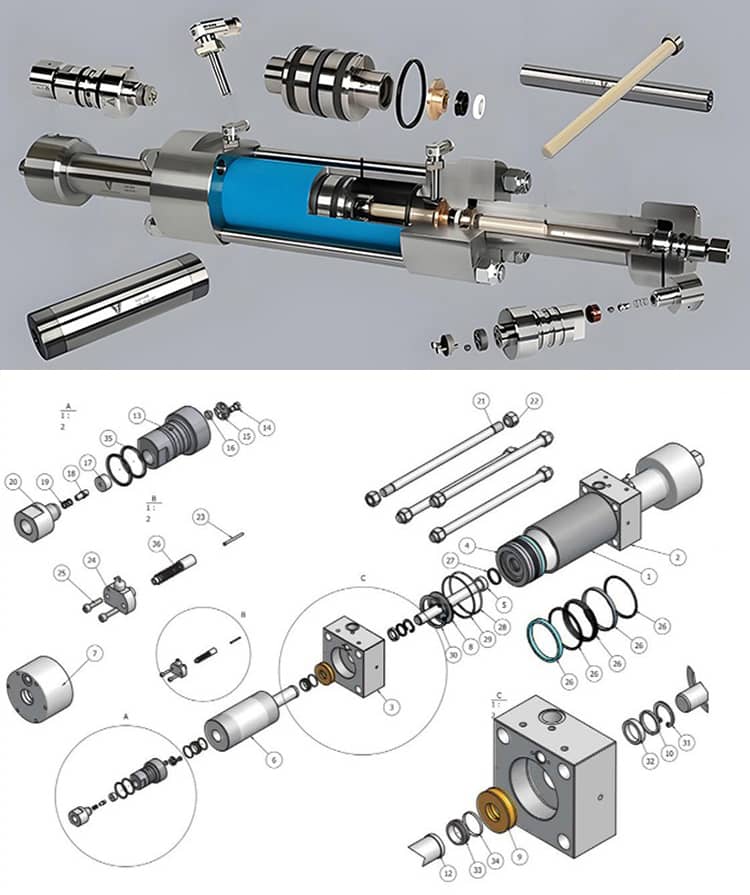

Working Principle Intensifier In Water Jet Machining:

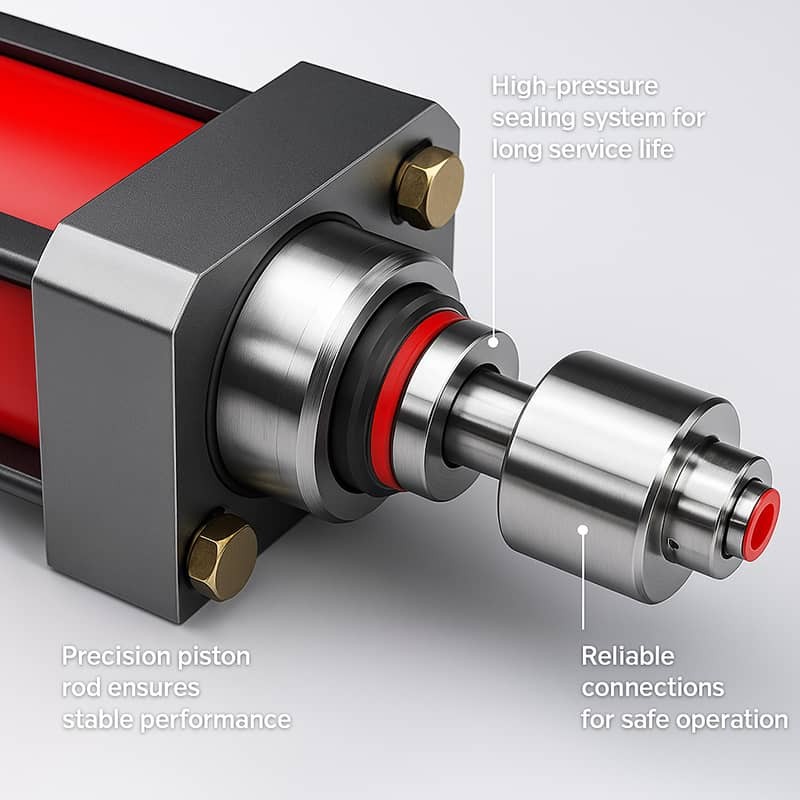

High-pressure Pump Water Supply: A booster or high-pressure pump compresses the water to a pressure of 3,000–6,000 bar (approximately 40,000–90,000 psi).Accumulator Energy Storage: High-pressure water enters the accumulator, pushing the internal diaphragm/piston, storing a certain amount of energy within the accumulator.

Stable Output: When water flow demand fluctuates suddenly during the cutting process, the accumulator can quickly replenish or absorb water, preventing pressure fluctuations.

Continuous Cutting: Ensures a stable high-pressure water jet from the nozzle, resulting in higher cutting precision and smoother cuts.

Purpose and Advantages Intensifier In Water Jet Machining:

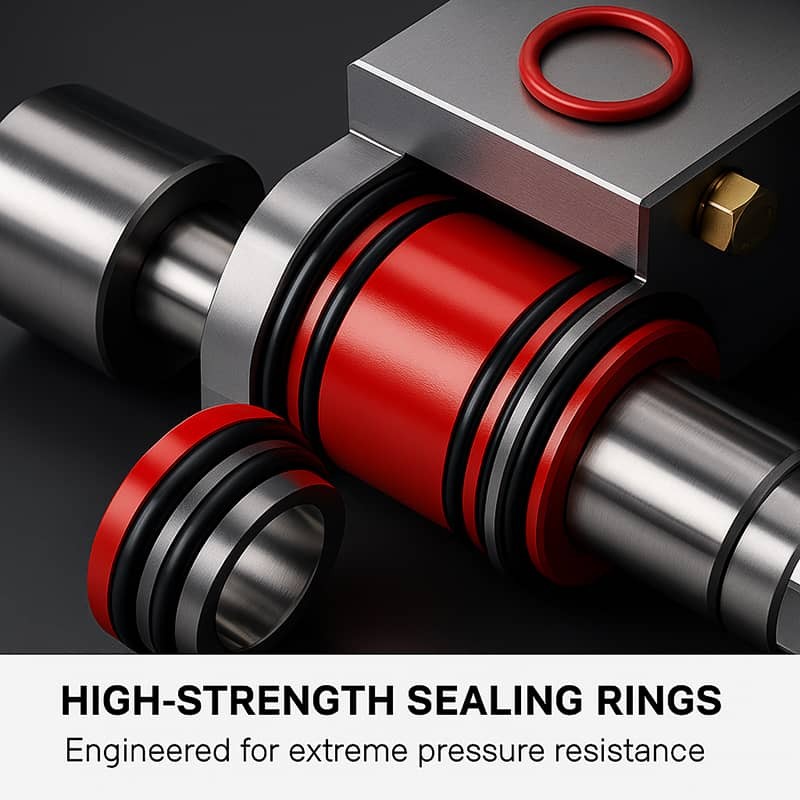

Stable Pressure: Avoids fluctuations caused by direct pump output.

Improved Cutting Quality: Ensures a continuous jet flow and smoother cuts. Extend equipment life: Reduce pressure shock in the booster and piping.

Energy savings and consumption reduction: Reduce frequent pump starts and stops, improving efficiency.

INQUIRY