Flat Poppets Sealing Head Repair Kit 05133335 Abrasive Water Jet Parts Supplier

Flat Poppets Sealing Head Repair Kit 05133335 Abrasive Water Jet Parts Supplier

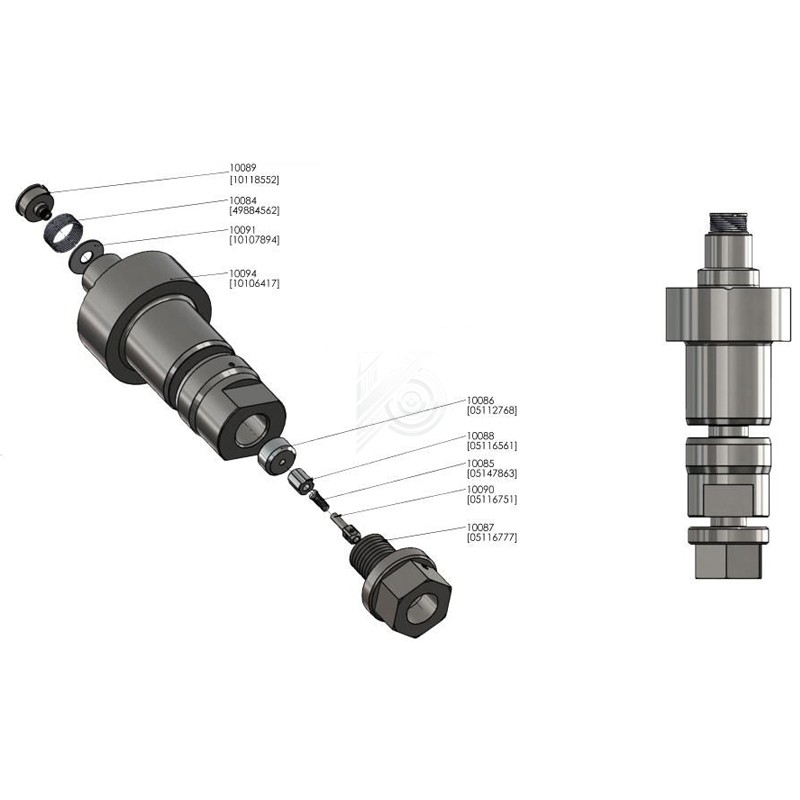

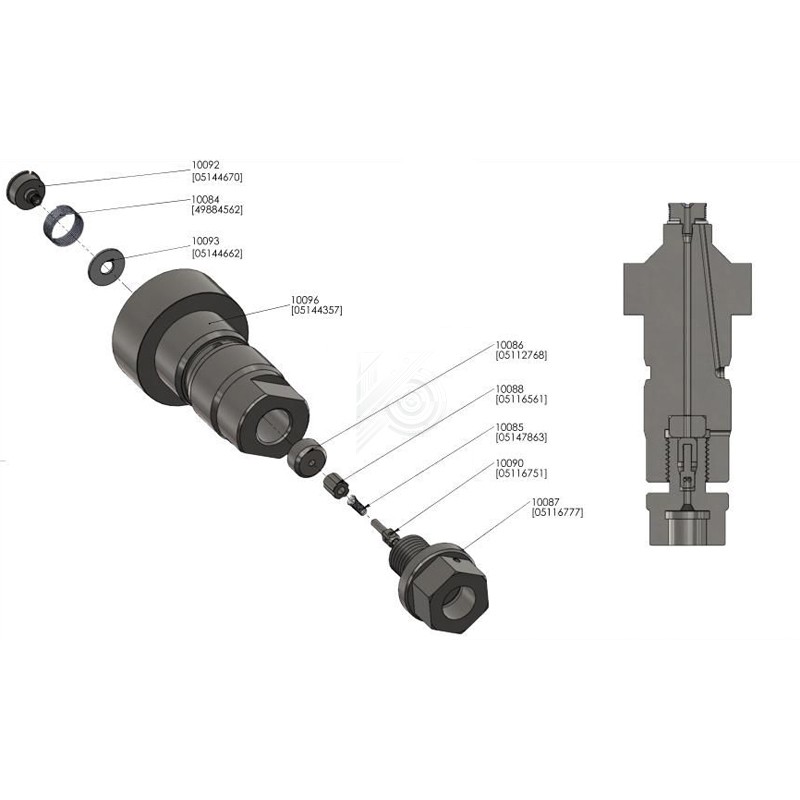

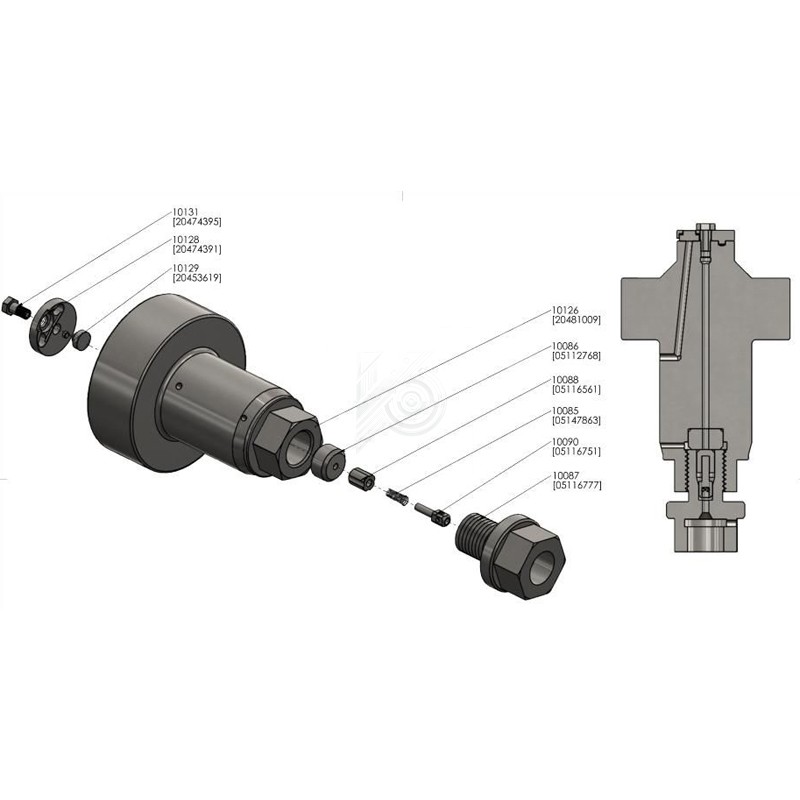

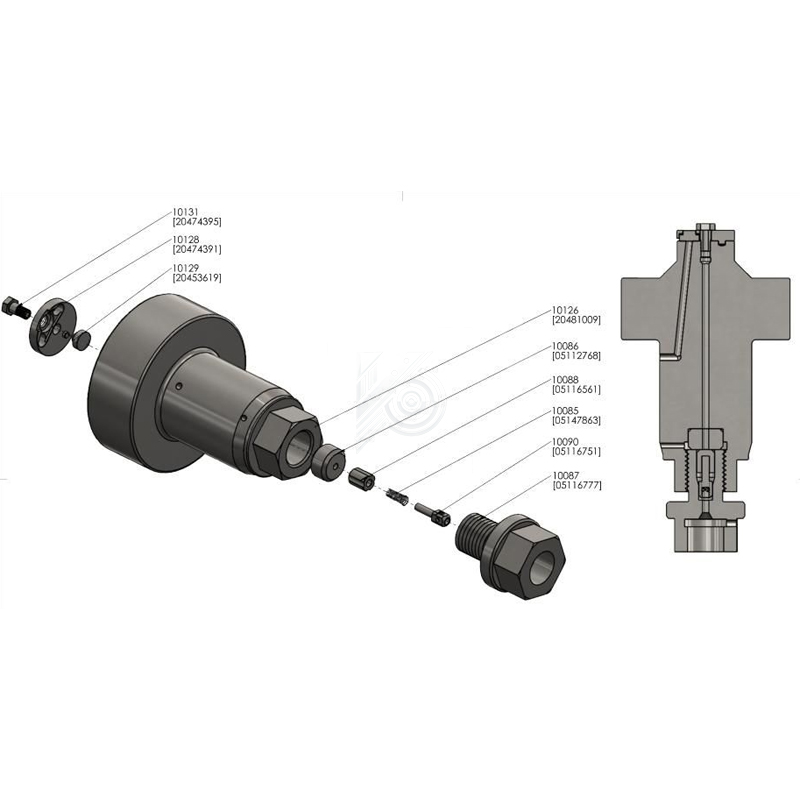

Kit Contents

The kit includes the complete set of wear parts for the flat‑poppet outlet valve:

05112768 – Flat Outlet Poppet Seat

05116561 – Flat Outlet Poppet (Check Valve)

05116751 – Spring Guide for Flat Outlet Poppet

05147863 – Flared Compression Spring for Flat Outlet Poppet