Backup Ring Assembly 302244 High Quality Waterjet Cutting Machines Parts

Short Description:

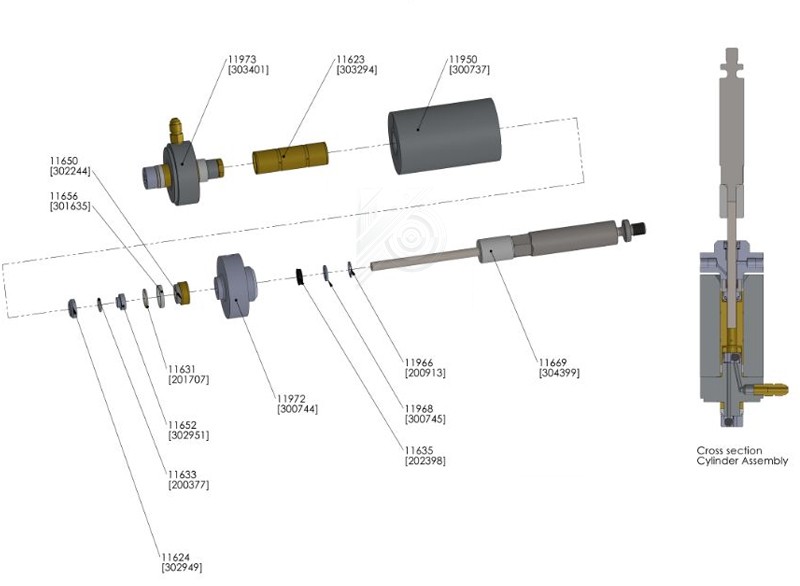

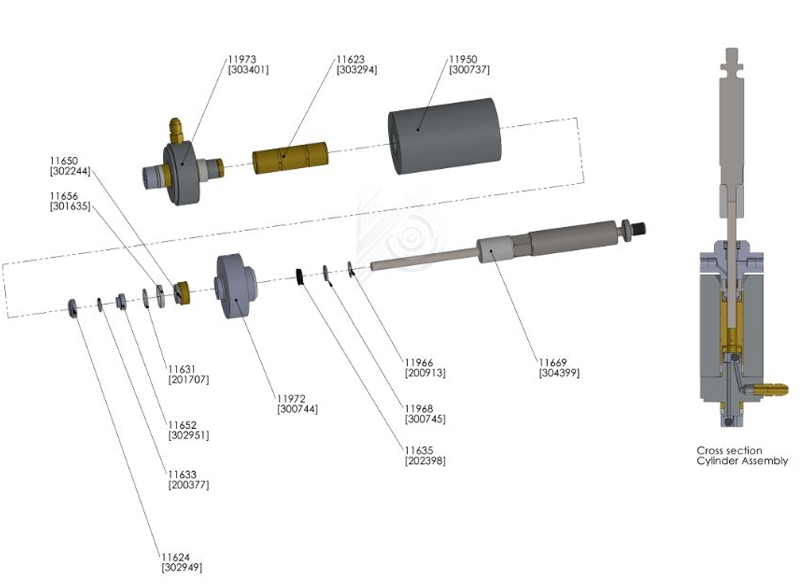

Parts:302244 Backup Ring Assembly,Omax Waterjet Parts Article number: 11650 Replaces: 302244, 301894; 11987 Function: Acts as a backup ring in the high-pressure seal assembly Material: Typically made of durable materials to withstand high-pressure conditions Compatibility: Designed for waterjet systems

Details

Backup Ring Assembly 302244 High Quality Waterjet Cutting Machines Parts

Specifications

Part Number: 302244

Replaces: 302244, 301894; 11987

Function: Acts as a backup ring in the high-pressure seal assembly

Material: Typically made of durable materials to withstand high-pressure conditions

Compatibility: Designed for waterjet systems

Product recommendation

Drive Cylinder CP022002/190 Abrasive Water Jet Pump Parts In Stock

Waterjet Coil P24602494 Axis 2 IRB 2400 M94 With Good Quality Robotic Waterjet Parts For Sale

Single Port Abrasive Nozzle Assembly 0.33 mm 20477959013 KMT Waterjet Parts For Sale

3/8 Tube Clamp Pair 1-13144 Good Quality High Pressure Waterjet Tube Parts

Waterjet Connection Flange CP022016/172 Waterjet Intensifier Pump Parts

87K Intensifier Check Valve Outlet 014885-1 Waterjet Side Maintenance Kit

HP Seal kit 20467135 SLV 75s-100s Hybrid Water Jet Parts Supplier