Industry-news

What Are the Functions of a Five-Axis Waterjet Cutting Head?

What Are the Functions of a Five-Axis Waterjet Cutting Head?

Five-axis waterjet cutting technology has revolutionized precision cutting by expanding the capabilities of traditional three-axis systems. With the ability to cut complex shapes, perform angled cuts, and create intricate designs, five-axis waterjet cutting heads have become indispensable in industries such as aerospace, automotive, metal fabrication, and architecture. In this article, we’ll explore the primary functions of a five-axis waterjet cutting head and how it adds value to modern manufacturing processes.

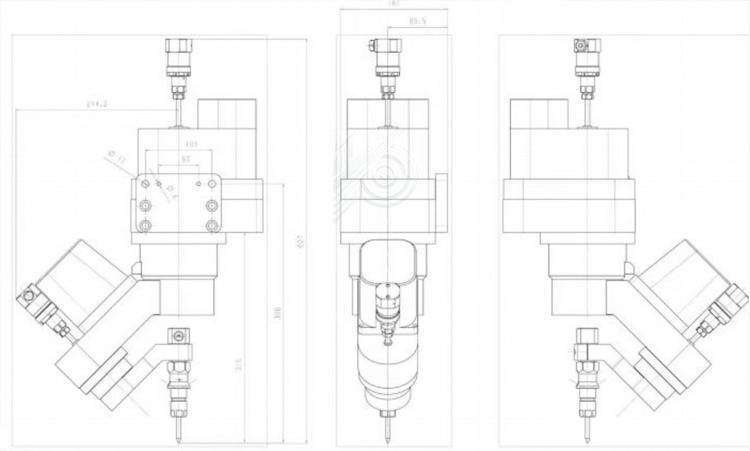

A-axis Rotating Range

±70。

C-axis Rotating Range

Infinite

Positioning Precision

1.5’

Max Rotational Speed

50RPM

Cutting precision at fixed point

±0.05mm

Rotating Radius

261mm

Automatic Heigh Measurement

No (The automatic height measurement function requires an additional charge)

Main Measurement

Max. Height

607mm

Max. Length

376mm

Max. Width

161mm

High Pressure Tube Inlet Threading

1/4 Inch

1. Angled Cutting for Complex Designs

A five-axis waterjet cutting head allows for precise angled cuts, enabling the machine to cut materials at a wide range of angles, typically between 0° and 70°. This capability is crucial for creating beveled edges, countersinks, and other complex geometries that are impossible with a three-axis cutting head.

- Function: The cutting head can tilt in multiple directions, enabling accurate slanted cuts for parts requiring angled edges or interlocking components.

- Application: Commonly used for aerospace components, automotive parts, and architectural panels where precise angles are critical.

2. Simultaneous Multi-Axis Movement (Full Five-Axis Control)

The five-axis Waterjet Cutting System operates by coordinating the X, Y, Z, A, and B axes simultaneously. This synchronized motion allows the cutting head to follow intricate 3D paths, making it ideal for cutting complex contours and shapes.

- Function: Full five-axis movement enables the machine to produce parts with sophisticated geometries, such as turbine blades, impellers, and curved surfaces.

- Application: Essential in industries requiring precision 3D cutting, such as aerospace for jet engine components and medical for custom implants.

3. Compensation for Taper and Kerf

Traditional waterjet cutting systems often produce tapered edges due to the natural divergence of the water and abrasive stream. Five-axis cutting heads address this issue by automatically adjusting the angle of the jet to compensate for taper, resulting in straight and uniform cuts.

- Function: Advanced software calculates the necessary adjustments to maintain consistent edge quality, even on thick materials.

- Application: Ensures precision in applications such as die-cutting tools, high-tolerance metal parts, and stone inlays.

4. Ability to Process Complex Materials

Five-axis waterjet cutting heads can handle a wide range of materials, including metals, composites, glass, ceramics, and even layered materials. The ability to tilt the cutting head enhances the machine's flexibility, making it suitable for challenging materials and intricate designs.

- Function: Adjusting the cutting angle improves cutting efficiency and reduces the risk of delamination or cracking in delicate materials.

- Application: Used for cutting laminated glass, carbon fiber, and multi-material assemblies.

5. Precision Cutting Without Heat-Affected Zones (HAZ)

Unlike traditional cutting methods such as laser or plasma cutting, waterjet cutting produces no heat-affected zones (HAZ). The five-axis cutting head further enhances this advantage by allowing precision cuts on complex shapes without compromising material properties.

- Function: Achieves clean cuts without altering the material's structural integrity.

- Application: Critical for aerospace, medical, and electronics industries where material performance is paramount.

6. Beveling and Edge Preparation

One of the standout features of a five-axis cutting head is its ability to perform beveling directly during the cutting process. This eliminates the need for secondary machining or manual finishing, saving time and reducing production costs.

- Function: Creates beveled edges for welding, assembly, or decorative purposes in a single operation.

- Application: Frequently used in shipbuilding, construction, and pipeline manufacturing for preparing parts for seamless assembly.

7. Enhanced Flexibility for Customization

With the five-axis cutting head, manufacturers can achieve unparalleled flexibility in customizing parts. The ability to adjust cutting angles and paths allows for rapid prototyping and production of intricate designs without extensive tooling changes.

- Function: Enables quick adjustments to designs and cuts, accommodating unique project requirements.

- Application: Ideal for industries with high customization demands, such as jewelry, interior design, and art installations.

8. Compatibility with Advanced Software

Five-axis waterjet cutting systems are typically integrated with advanced CAD/CAM software, allowing users to create and execute complex cutting programs with ease. The software ensures precise coordination of all five axes, enabling smooth and accurate cuts.

- Function: Simplifies programming and execution of multi-axis cutting paths while minimizing errors.

- Application: Reduces setup time and enhances productivity in precision manufacturing.

9. Increased Productivity and Efficiency

The multi-axis capability of a five-axis waterjet cutting head significantly reduces the need for repositioning the material or performing secondary operations. This not only speeds up production but also minimizes material waste.

- Function: Performs multiple types of cuts in a single operation, reducing processing time and costs.

- Application: Boosts productivity in industries with high-volume or complex cutting requirements, such as automotive and heavy machinery manufacturing.

Conclusion

A five-axis waterjet cutting head is a game-changer for industries that require precision, versatility, and efficiency. Its ability to cut at various angles, follow complex paths, and produce high-quality results makes it an indispensable tool for modern manufacturing. Whether you're creating intricate 3D parts, preparing beveled edges, or cutting complex materials, the five-axis waterjet cutting system offers unmatched capabilities.

Investing in a five-axis WaterJet Cutting Machine not only enhances cutting performance but also improves overall productivity, reduces material waste, and enables businesses to tackle more complex projects. If you're considering upgrading your cutting equipment, a five-axis waterjet system is a smart choice for staying ahead in today’s competitive manufacturing landscape.