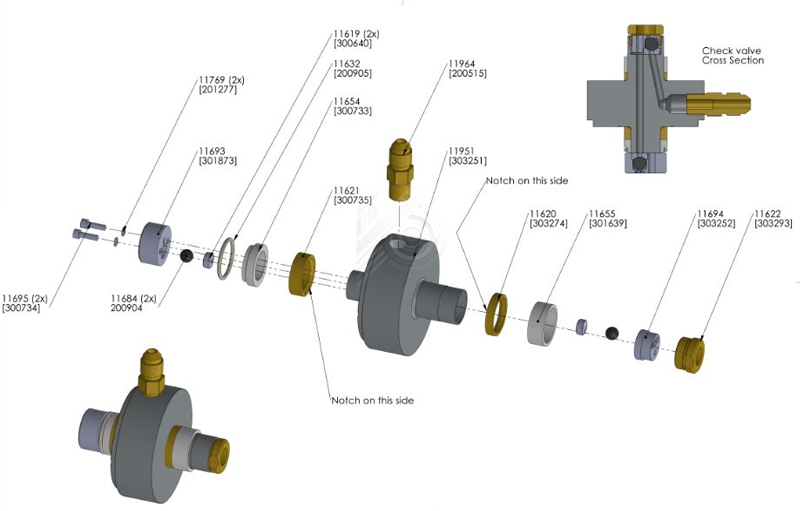

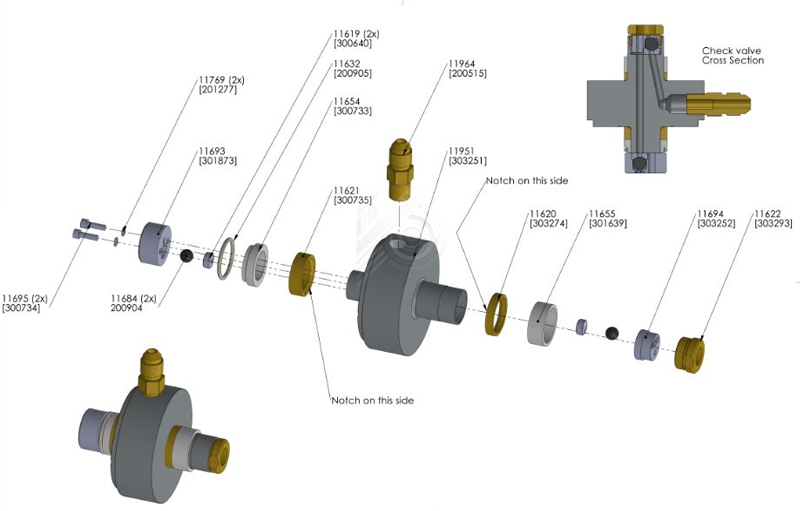

1/4 Ceramic Ball 200904 High Quality Waterjet Cutting Machines Parts

1/4 Ceramic Ball 200904 High Quality Waterjet Cutting Machines Parts

INQUIRY

Tel.: +86-15793670759

Phone: +86-15793670759

E-mail: info@kundacnc.com

Whatsapp: +86-15793670759

Add.: OVU Maker Apartment, No. 12 Qixing Street, Shenbei New District, Shenyang, China