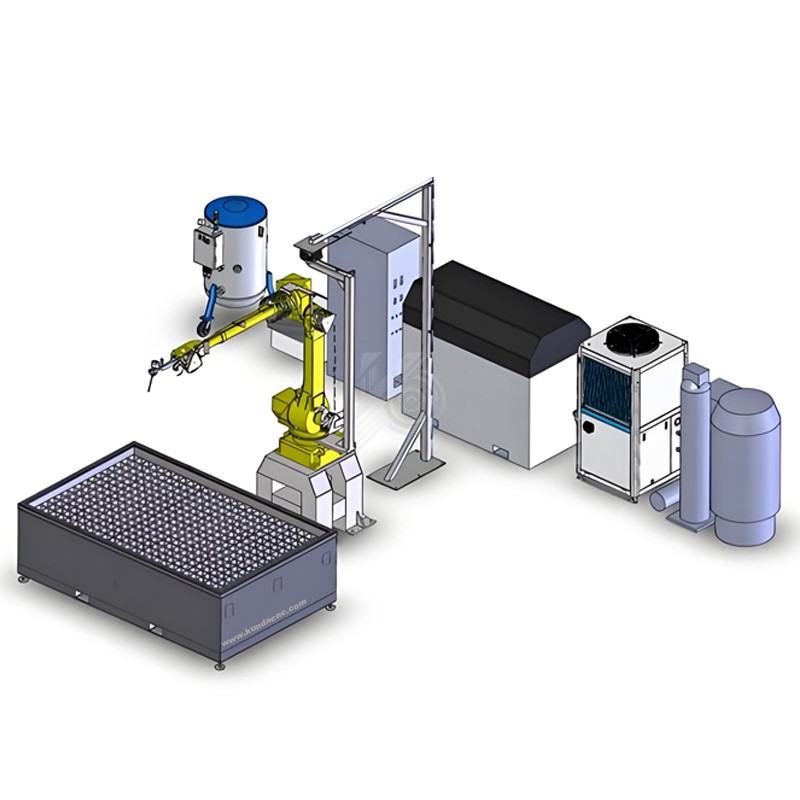

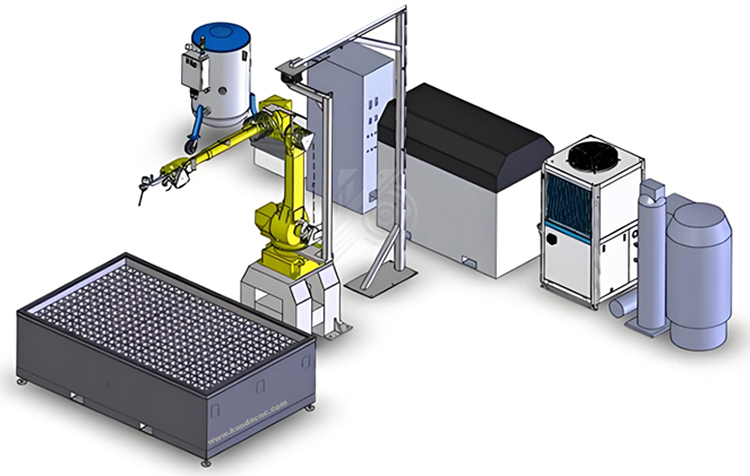

Water Jet Cutting Machine Inverted Triple Hand Yaskawa GP20HL Robot Cut For Luggage Racks

Water Jet Cutting Machine Inverted Triple Hand Yaskawa GP20HL Robot Cut For Luggage Racks

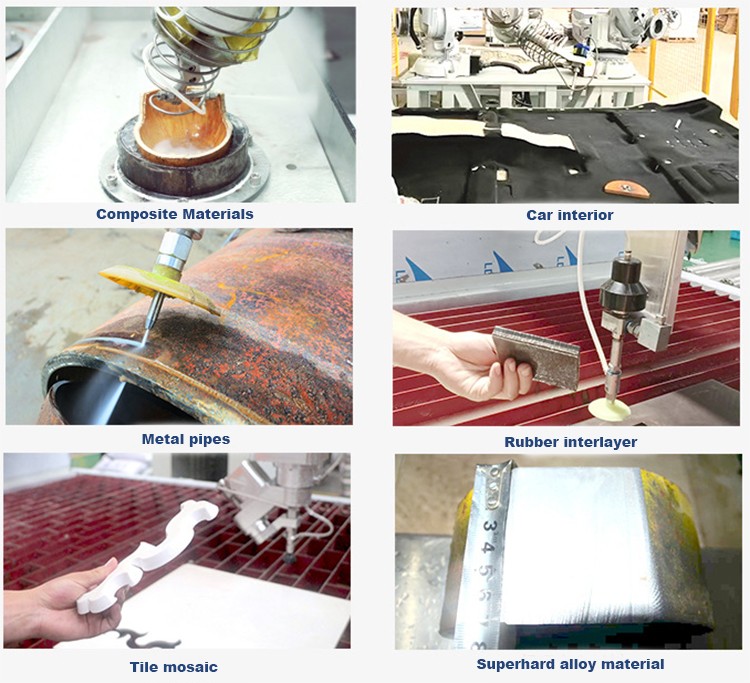

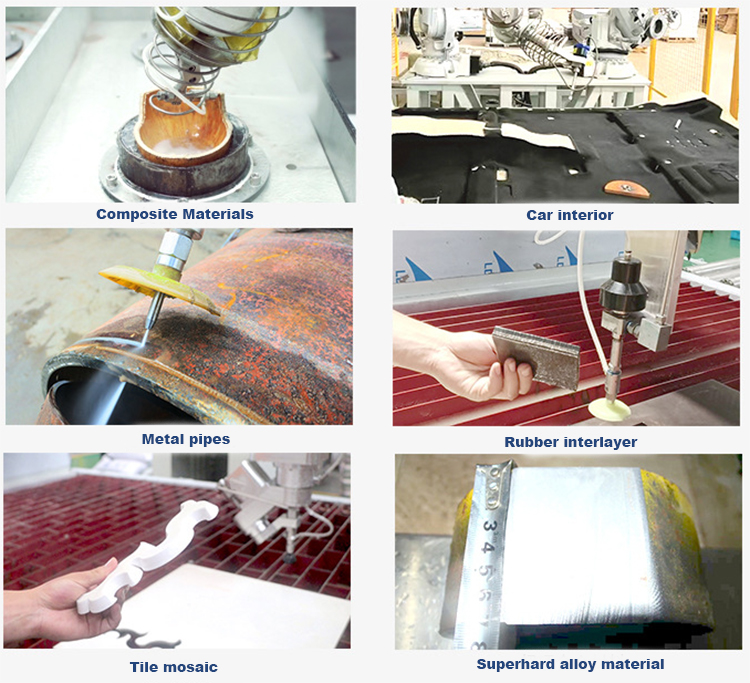

Robotic water jet cutting is specifically used in the following industries:

- Industrial manufacturing: Robotic water jet cutting machines can accurately cut various metal and non-metal materials, such as steel, aluminum, etc. In the automotive, aviation and other manufacturing industries, robotic water jet cutting machines are widely used in the cutting of high-precision parts to meet the high requirements for accuracy and operating speed.

- Medical technology: With the development of the medical industry, the requirements for equipment accuracy and operating speed are increasing. Robotic water jet cutting machines can accurately remove diseased tissues or tumors without damaging surrounding tissues due to their high precision and low temperature cutting characteristics. They can also be used to make medical devices such as micro-devices or stents.

- Military equipment: The military has extremely high requirements for the reliability and accuracy of equipment. In the manufacture of military equipment, robotic water jet cutting machines can cut high-precision, high-quality parts to meet the requirements of military equipment for accuracy and durability.

- Automotive interior cutting: Robotic water jet cutting has become the mainstream technology for automotive interior cutting. It can process various automotive interior materials, such as plastics, leather and fabrics, and cut parts of various shapes and sizes through a combination of high-pressure water flow and sand particles, improving cutting accuracy and efficiency while reducing labor costs and waste generation.

- Environmental protection industry: Robotic water cutting also plays an important role in some environmental protection applications. For example, when using high-pressure water cutting for fine 3D cutting tasks, it will not produce thermal fatigue and non-toxic smoke, which meets environmental protection requirements.

The Water Jet Cutting Machine is an advanced manufacturing solution designed to deliver exceptional precision and versatility in material processing. Utilizing a high-pressure stream of water, often mixed with abrasives, this machine can cut through a wide variety of materials, including metal, glass, stone, ceramics, composites, and even delicate materials like foam or rubber. Its cold-cutting process ensures there is no heat-affected zone, preserving material integrity and eliminating the need for secondary finishing.

Key features of the Water Jet Cutting Machine include its ability to handle intricate designs with high accuracy, its environmental benefits through water recycling systems, and its user-friendly interface for seamless operation. This machine is suitable for various industries such as aerospace, automotive, construction, and custom fabrication, offering solutions for tasks ranging from precision cutting to large-scale industrial applications.

The machine’s flexibility is enhanced by options for 2D and 3D cutting, making it a versatile tool for complex projects. With robust construction and low maintenance requirements, it guarantees reliable performance and reduced downtime. By incorporating a Water Jet Cutting Machine into your production process, you can achieve superior efficiency, reduced material waste, and exceptional quality, helping your business stay competitive in today’s market.