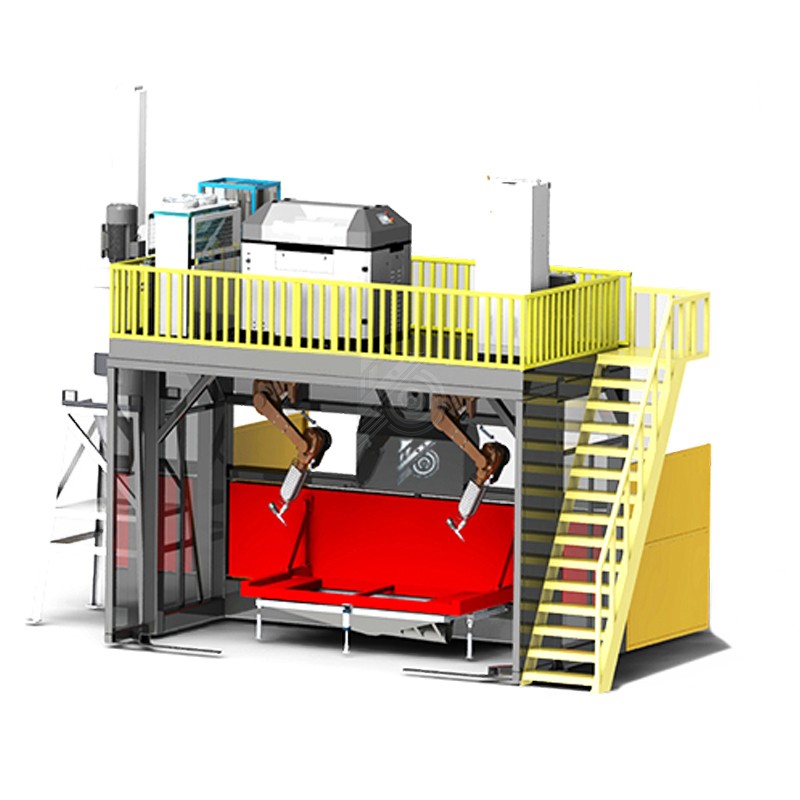

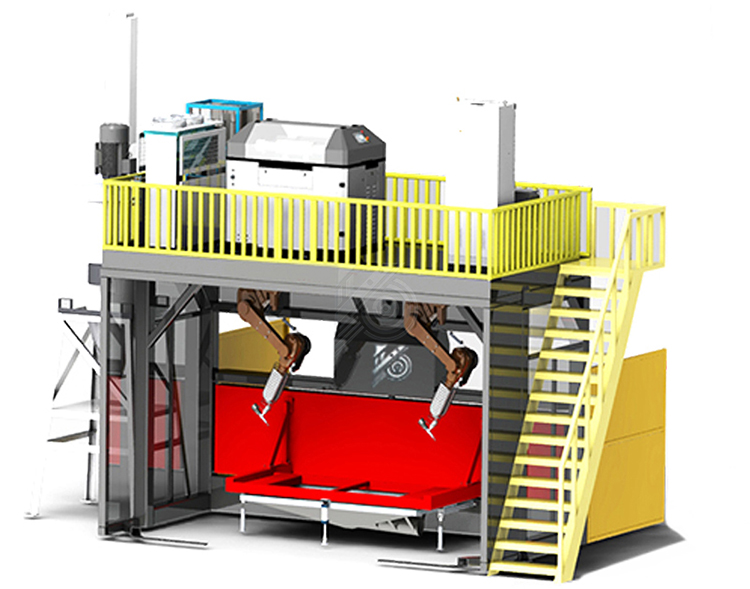

Robot Waterjet Seated Double Hand ABB2400 Good Cutter For Luggage Racks

Robot Waterjet Seated Double Hand ABB2400 Good Cutter For Luggage Racks

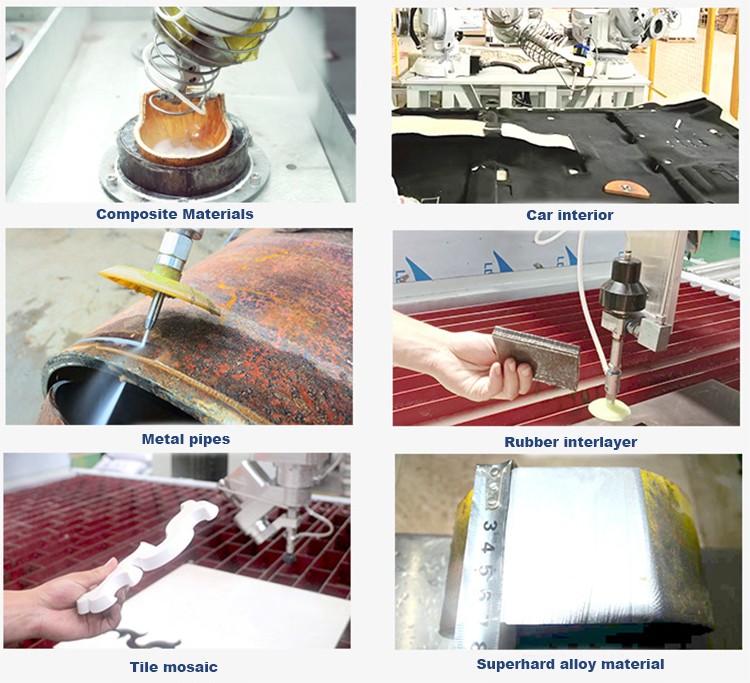

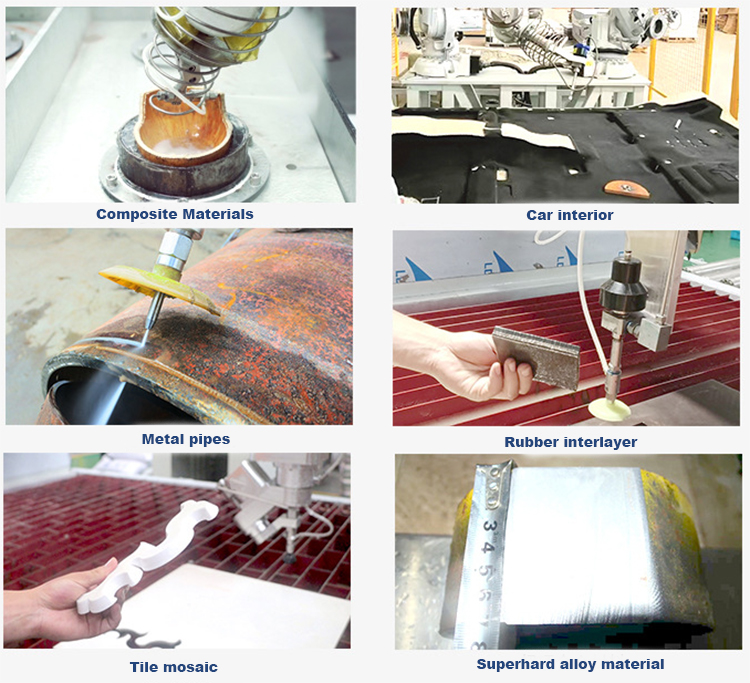

Robotic water jet cutting is specifically used in the following industries:

Industrial manufacturing: Robotic water jet cutting machines can accurately cut various metal and non-metal materials, such as steel, aluminum, etc. In the automotive, aviation and other manufacturing industries, robotic water jet cutting machines are widely used in the cutting of high-precision parts to meet the high requirements for accuracy and operating speed.

Medical technology: With the development of the medical industry, the requirements for equipment accuracy and operating speed are increasing. Robotic water jet cutting machines can accurately remove diseased tissues or tumors without damaging surrounding tissues due to their high precision and low temperature cutting characteristics. They can also be used to make medical devices such as micro-devices or stents.

Military equipment: The military has extremely high requirements for the reliability and accuracy of equipment. In the manufacture of military equipment, robotic water jet cutting machines can cut high-precision, high-quality parts to meet the requirements of military equipment for accuracy and durability.

Automotive interior cutting: Robotic water jet cutting has become the mainstream technology for automotive interior cutting. It can process various automotive interior materials, such as plastics, leather and fabrics, and cut parts of various shapes and sizes through a combination of high-pressure water flow and sand particles, improving cutting accuracy and efficiency while reducing labor costs and waste generation.

Environmental protection industry: Robotic water cutting also plays an important role in some environmental protection applications. For example, when using high-pressure water cutting for fine 3D cutting tasks, it will not produce thermal fatigue and non-toxic smoke, which meets environmental protection requirements.

The Robot Waterjet combines advanced robotic automation with cutting-edge waterjet cutting technology, providing unmatched precision and versatility for a wide range of industrial applications. Designed to handle complex cutting tasks, this system is ideal for industries such as aerospace, automotive, and manufacturing, where accuracy, speed, and material integrity are essential.

The Robot Waterjet employs a multi-axis robotic arm, enabling it to perform precise cuts on both flat and three-dimensional surfaces. This flexibility allows for intricate patterns and shapes to be cut with ease, even in challenging-to-access areas. The integration of ultra-high-pressure waterjet technology ensures clean, burr-free cuts without the need for post-processing, saving time and reducing costs.

One of the key advantages of the Robot Waterjet is its non-thermal cutting process, which eliminates the risk of heat-induced material warping. This makes it ideal for delicate materials such as composites, glass, and thin metals. Additionally, the system can incorporate abrasive materials to enhance cutting power, making it capable of slicing through even the toughest materials with precision.

The robotic automation of this system streamlines production workflows, reduces labor requirements, and ensures consistent quality across high-volume production runs. Its programmable nature allows for quick task adjustments, making it equally effective for custom one-off projects or mass manufacturing.

Environmentally friendly and efficient, the Robot Waterjet minimizes waste and can be equipped with water recycling systems, aligning with sustainable manufacturing practices. For businesses looking to elevate their cutting capabilities, this innovative solution delivers exceptional performance, adaptability, and reliability.