Liquid Displacer 303294 High Quality Waterjet Cutting Machines Parts

Short Description:

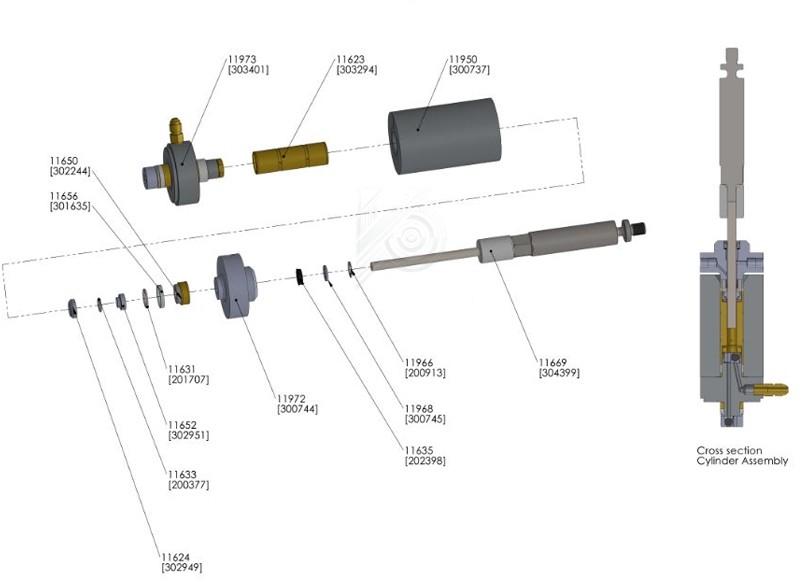

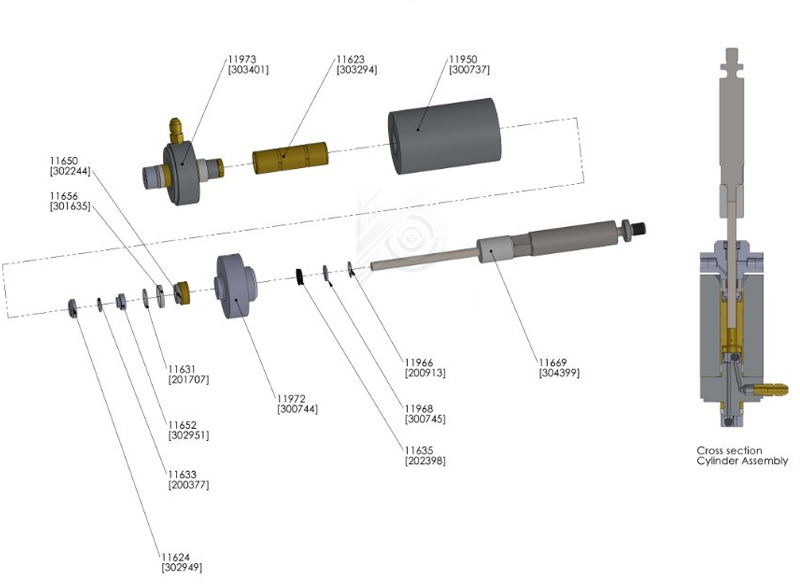

Parts:303294 Liquid Displacer,Omax Waterjet Parts Article number: 11623 Material: Copper Beryllium Function: Displaces liquid within the pump assembly to maintain optimal pressure and performance

Details

Liquid Displacer 303294 High Quality Waterjet Cutting Machines Parts

Specifications

Material: Copper Beryllium

Function: Displaces liquid within the pump assembly to maintain optimal pressure and performance

Product recommendation

Heat Exchanger A-3478 Shell/Tube Abrasive Waterjet Parts In Stock

Mounting Stem Gasket 05081872 Abrasive Water Jet Parts

ECL Composite Orifice 0.30MM GKC-01-12 Abrasive Waterjet Cutting Machine Parts

87K Whip 040300-1 Flow Water Jet Parts

Sealing 3HAC022379-001 Axis 2/3 For Robot Water Jet Cutting Machine Parts In Stock

Inlet Body 303279 High Quality Waterjet Cutting Machines Parts

Hydraulic Cartridge Seal Repair Kit 80084759 Abrasive Water Jet Cutting Machine Parts