Jet Cutting Machine Lifting 5Axis Mini Water Jet Cutter Garnet Waterjet Cutting Machine

Jet Cutting Machine Lifting 5Axis Mini Water Jet Cutter Garnet Waterjet Cutting Machine

|

Specification of Cutting Table |

|

|

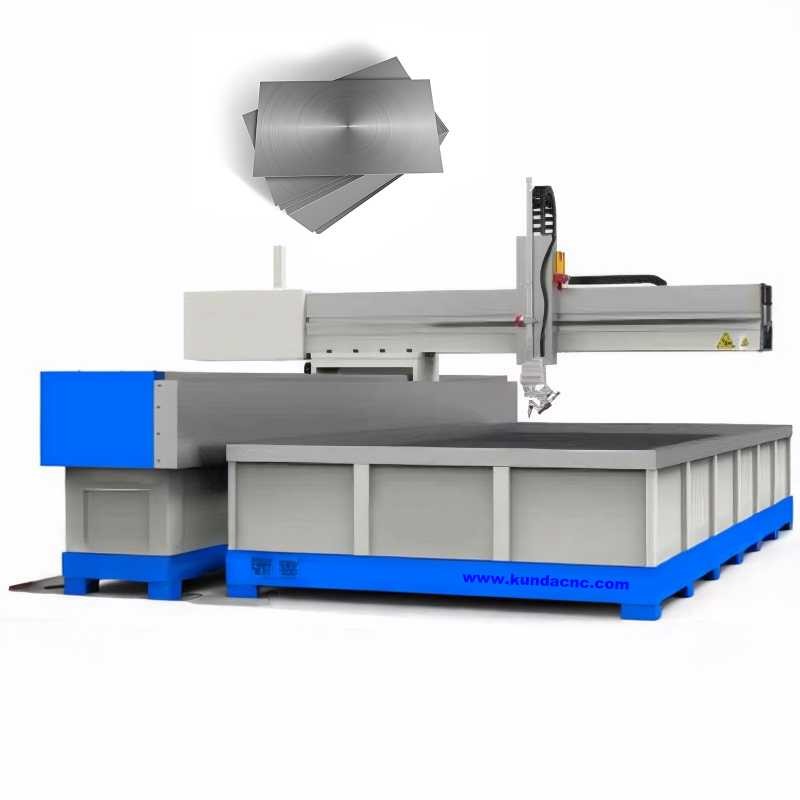

Structure |

5axis cantiliver Type |

|

Series |

AB-3015 5 axis Water Jet |

|

Table Size |

3000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

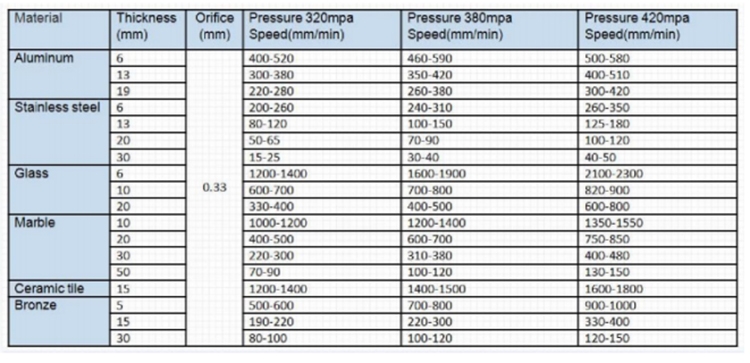

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

3000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

75KW/100HP |

|

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

7.6L/min |

|

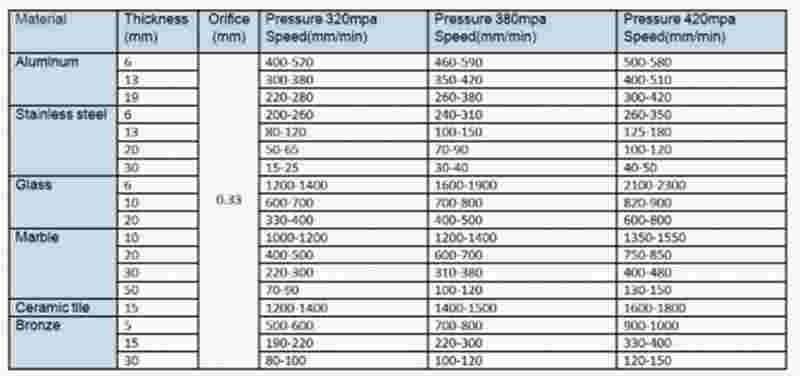

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

180L |

|

Size |

2120mm*1360mm*1510mm |

|

Weight |

1500kg |

Jet Cutting Machine refers to a high-pressure water jet cutting technology that uses a cantilever mechanical structure and combines abrasives. This equipment combines the kinetic energy of high-pressure water jets and the grinding effect of abrasives, and can efficiently cut a variety of hard materials (such as metals, stones, composite materials, etc.).

1. Basic principles Jet Cutting Machine

High-pressure water jet: water is pressurized by an ultra-high pressure pump (usually the pressure can reach 300-600 MPa) to form a high-speed jet.Abrasive addition: abrasives (such as pomegranate sand, aluminum oxide, etc.) are mixed in the high-pressure water flow to form a water-sand mixed jet to enhance cutting ability.

Cantilever structure: The equipment adopts a cantilever mechanical design, and the cantilever can move flexibly, which is suitable for cutting large-sized workpieces or complex shapes.

2. Equipment composition Jet Cutting Machine

Cantilever system: provides lateral and longitudinal freedom of movement, usually controlled by a numerical control system (CNC) to achieve high-precision cutting paths.High-pressure pump: core component, providing ultra-high pressure power for water jets.

Abrasive supply system: store and precisely control the mixing ratio of abrasives.

Cutting head: integrated nozzle (gem nozzle or diamond nozzle), adjust the water-sand mixed jet.

Control system: control cutting path, speed and pressure through programming or software.

3. Technical advantages Jet Cutting Machine

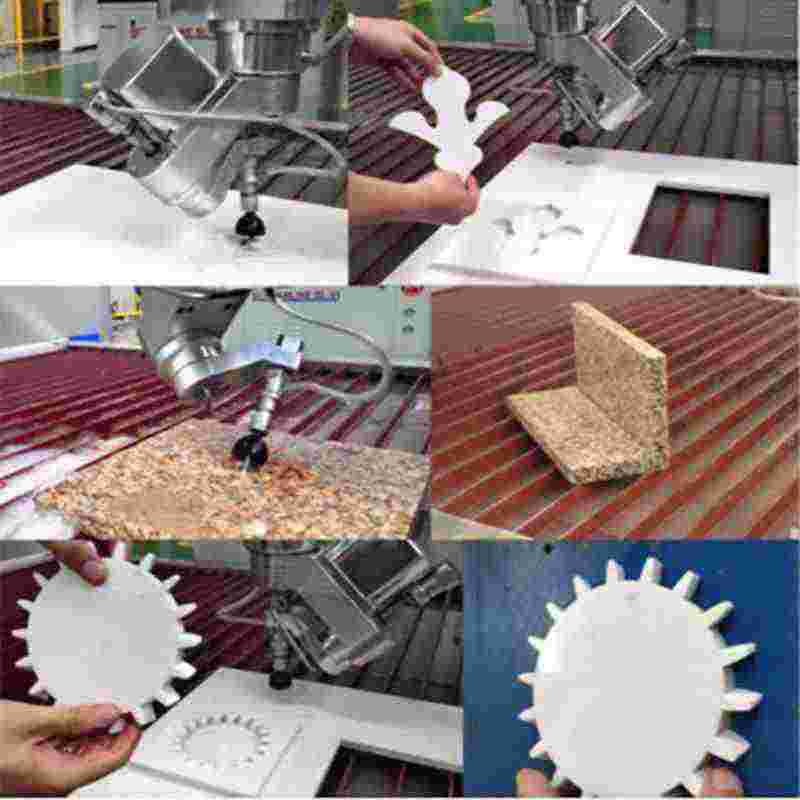

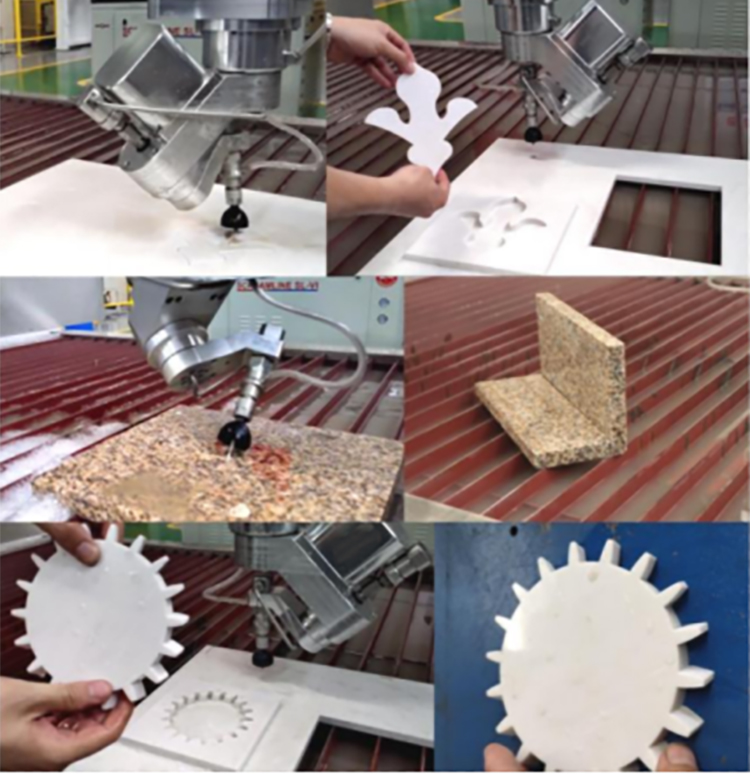

Wide applicability: can cut metal (sTeel, titanium alloy), stone, glass, ceramic, composite materials, etc.Cold cutting: no heat affected zone (HAZ), avoiding material deformation or performance change.

High precision: CNC system supports complex contour cutting with a tolerance of up to ±0.1mm.

Environmental protection and energy saving: no harmful gas or dust (water circulation system is required).

Flexibility: cantilever structure is suitable for large workpieces or small space operations.

4. Application areas Jet Cutting Machine

Industrial manufacturing: aerospace parts, automotive accessories, mechanical processing.Architectural decoration: stone carving, glass art cutting.

Energy industry: pipeline cutting, wind turbine blade trimming.

Composite material processing: carbon fiber, Kevlar and other difficult-to-cut materials.

5. Precautions Jet Cutting Machine

Safety: High-pressure water jets are extremely dangerous and require strict operating specifications and protective devices.Maintenance cost: Nozzles, high-pressure Seals and other vulnerable parts need to be replaced regularly.

Abrasive selection: Choose appropriate abrasives according to the hardness of the material (such as pomegranate sand for metals and aluminum oxide for stone).

Wastewater treatment: The wastewater after cutting needs to be filtered and the abrasive needs to be recycled to avoid environmental pollution.

6. Special advantages of cantilever structure

Wide Coverage: The cantilever can extend beyond the workbench, which is suitable for cutting extra-long or special-shaped workpieces.Space saving: Compared with the gantry structure, the cantilever design is more compact and suitable for scenes with limited workshop space.

Fast dynamic response: The lightweight cantilever structure can increase the cutting speed and reduce the idle time.

7. Typical technical parameters

Cutting pressure: 300-600 MPaCutting thickness:

Metal: up to 150mm (depending on the hardness of the material)

Stone: up to 200mm

Positioning accuracy: ±0.05mm

Cutting speed: 10-3000mm/min (depending on the material and thickness)

Other type of Waterjet Cutting Machine,please contact us!!!