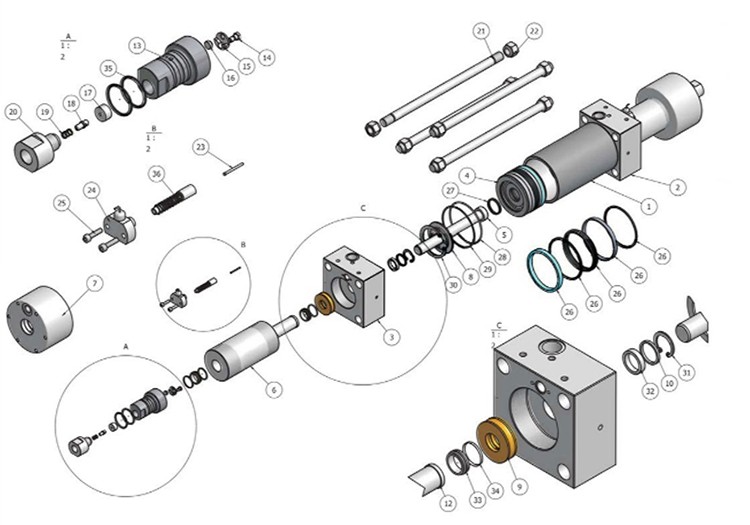

The Hydraulic Intensifiers is the core component of the water jet cutting system. Its main function is to pressurize ordinary water to an ultra-high pressure state, so that it has the ability to cut various materials. Its working principle is based on the "boosting principle", that is, using pistons of different areas to amplify the pressure. Specifically, the hydraulic oil is pressurized to about 3,000 psi (about 20.7 MPa) to push a piston with a larger area (called the "large piston"). The piston is connected to a plunger with a smaller area (called the "small piston"), which acts on the water. Since the area of the large piston is 20 times that of the small piston, the pressure is amplified 20 times, generating a water pressure of about 60,000 psi (about 413.7 MPa).

In actual applications, ordinary tap water is first filtered through a filter, then pressurized by a water pump and enters the high-pressure cylinder of the Hydraulic Intensifiers. When the oil piston reciprocates, water enters the high-pressure cylinder at one end through the water inlet check valve, and the water in the high-pressure cylinder at the other end is pushed out and enters the high-pressure pipeline through the water outlet check valve. This alternating action forms a continuous high-pressure water flow. Due to the switching cycle of the booster, the output water flow pressure will fluctuate periodically, so it is necessary to stabilize the pressure through a high-pressure accumulator to ensure the stability of the cutting process.

The Hydraulic Intensifiers produced by Kunda has a stable working state and guaranteed quality.

If you need more details,Please contact us!