Flow Jet Cutter Automotive Glass Big Abrasive Cutting Table For High Pressure Water Machine

Flow Jet Cutter Automotive Glass Big Abrasive Cutting Table For High Pressure Water Machine

|

Specification of Cutting Table |

|

|

Structure |

5axis cantiliver Type |

|

Series |

AB-3015 5 axis Water Jet |

|

Table Size |

3000mmx1500mm |

|

Cutting accuracy |

±0.1mm |

|

Re-position accuracy |

±0.05mm/m |

|

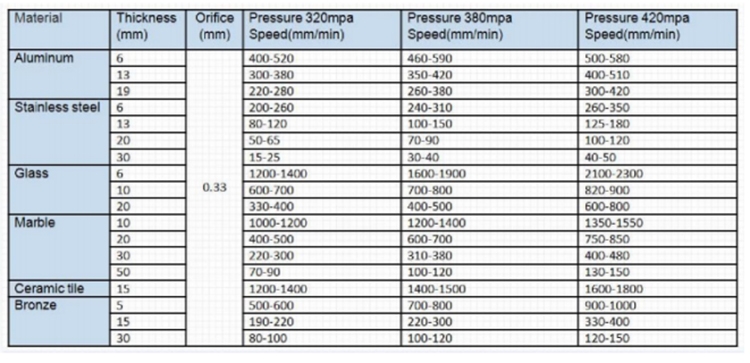

Cutting speed |

11000mm/min |

|

MAX.Cutting Range |

3000mmx1500mm |

|

Motor |

30kw / 40HP |

|

Certificate |

CE ISO |

|

Max swing angle |

±10° |

|

Swing angle accuracy |

±0.01° |

|

Specification of Cutting Table |

|

|

Rated Power |

75KW/100HP |

|

Max. operating pressure |

420MPa/4137bar/60000psi |

|

Continuous working pressure |

320MPa-380MPa |

|

Max. discharging rate |

7.6L/min |

|

Orifice diameter |

0.33mm or others |

|

Nozzle diameter |

1.02mm or others |

|

Tank volume |

180L |

|

Size |

2120mm*1360mm*1510mm |

|

Weight |

1500kg |

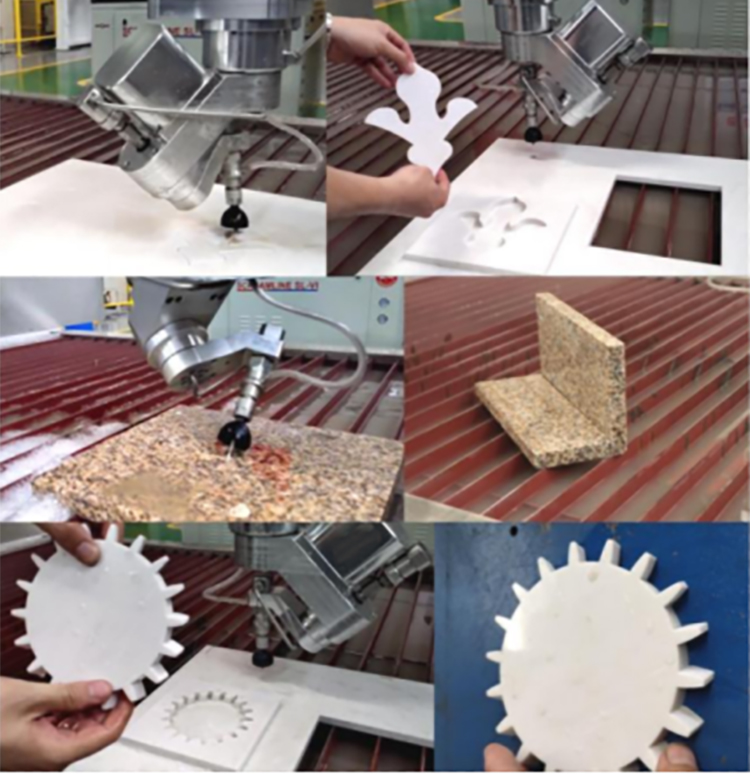

The Flow Jet Cutter is a top-tier industrial cutting machine designed to achieve precise, efficient cuts on a broad spectrum of materials. Using ultra-high-pressure water mixed with fine abrasives, this machine is capable of delivering clean, smooth cuts without producing heat, eliminating the risk of thermal distortion, cracking, or material damage. It is an ideal choice for industries such as aerospace, automotive, architecture, and manufacturing, where precision and material quality are paramount.

With its advanced CNC control system, the Flow Jet Cutter can handle both delicate and tough materials, including metals, stone, glass, ceramics, plastics, and composites. The machine’s ability to cut at complex angles allows for intricate patterns and complex shapes, making it suitable for high-precision tasks as well as larger industrial projects. By minimizing material waste and optimizing cutting efficiency, this system supports cost-effective production, whether for high-volume manufacturing or custom designs.

The Flow Jet Cutter is engineered for durability and consistent performance, featuring a sturdy construction that withstands continuous operation in demanding environments. Its user-friendly interface simplifies programming, allowing operators to set up cuts with ease and speed, thereby enhancing productivity. The machine is also energy-efficient and low-maintenance, reducing long-term operational costs for businesses.

For companies looking to upgrade their manufacturing capabilities, the Flow Jet Cutter provides an ideal solution that combines precision, flexibility, and efficiency. This cutting-edge machine is designed to elevate production standards and expand possibilities in industrial cutting, meeting the needs of businesses that prioritize innovation and quality.

Other type of WaterJet Cutting Machine,please contact us!!!