Check Valve Retainer 301873 High Quality Waterjet Cutting Machines Parts

Short Description:

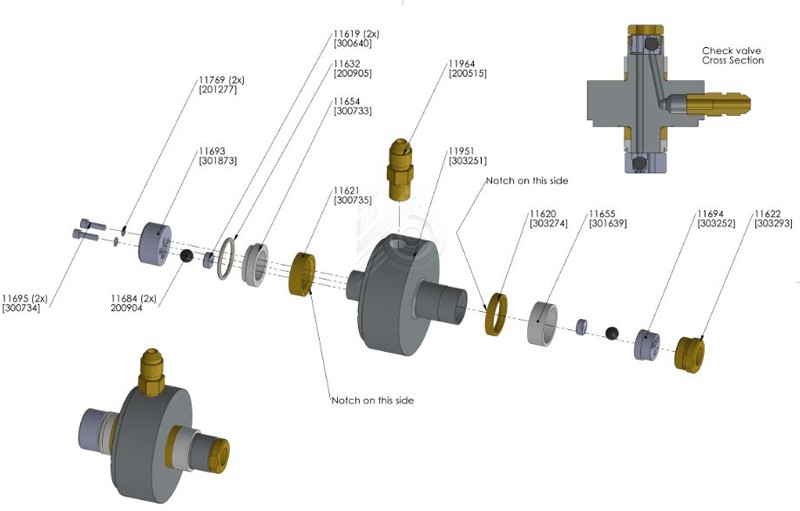

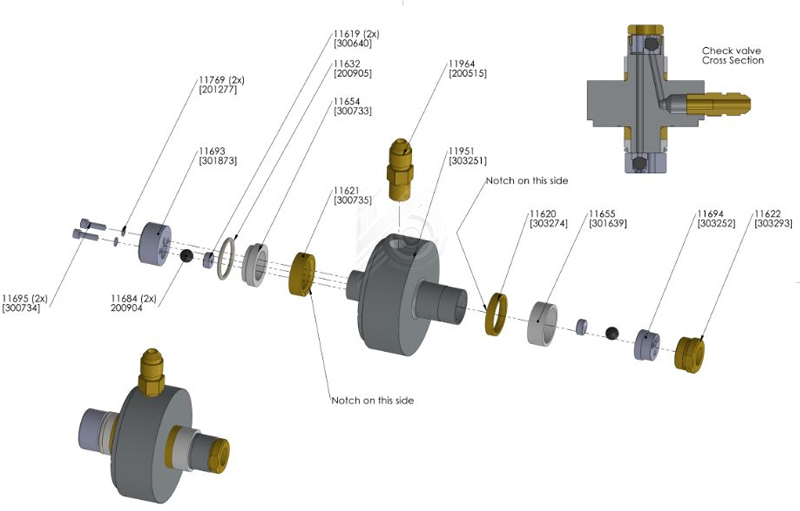

Parts:301873 Check Valve Retainer,Omax Waterjet Parts Article number: 11693 Material: Typically made from durable materials like stainless steel to withstand high-pressure environments. Function: Secures the check valve assembly, ensuring proper sealing and preventing leakage.

Details

Check Valve Retainer 301873 High Quality Waterjet Cutting Machines Parts

Specifications

OEM Part Number: 301873

Material: Typically made from durable materials like stainless steel to withstand high-pressure environments.

Function: Secures the check valve assembly, ensuring proper sealing and preventing leakage.

Installation & Maintenance Tips

Installation: Ensure the retainer is properly aligned and securely fastened to prevent misalignment and potential leakage.

Maintenance: Regularly inspect the retainer for signs of wear, corrosion, or deformation. Replace it if any damage is observed to maintain optimal performance of the check valve.

Lubrication: Apply a thin layer of compatible lubricant to the retainer during installation to reduce friction and wear, ensuring smooth operation.

Product recommendation

Valve Seat On/Off WS0013 Water Jet Parts

90000 Psi Water Good Price Abrasive Water Jet Cutting Machine For Granite

Guide Bushing CP020030/562 BFT Waterjet Parts Price

Waterjet Coil 106518 Axis 2 IRB 1600 With Good Quality Robotic Waterjet Parts For Sale

Focusing Tube WS0923 Good Price Waterjet Parts In Stock

Waterjet Coil 301097 Axis 3 IRB2400 With Good Quality Robotic Waterjet Parts For Sale

High Cycle Poppet Needle 1-13686 Water Jet Parts