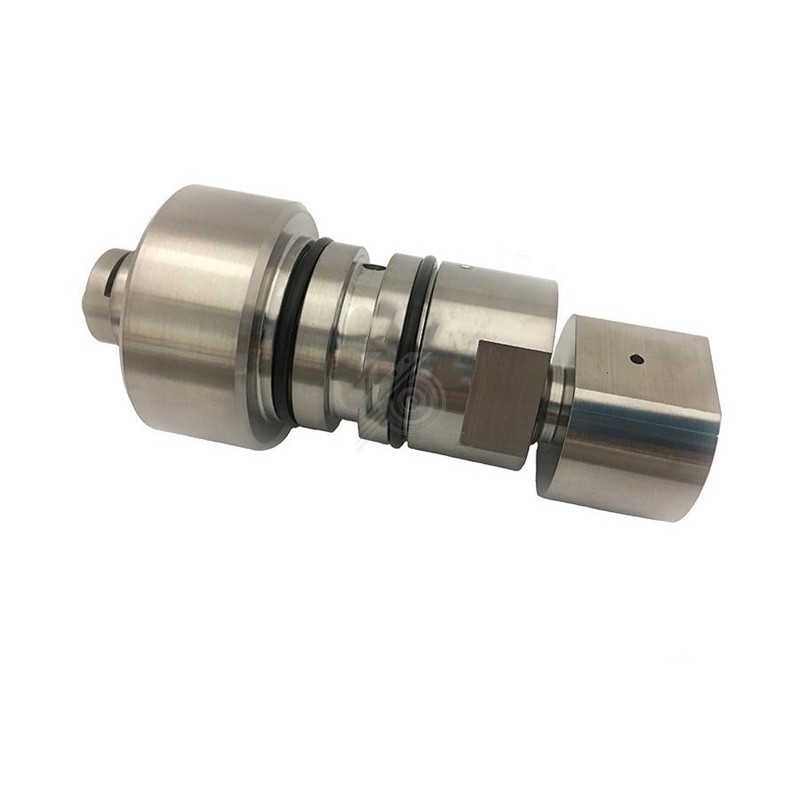

Check Valve Assembly WS2003 Ball In Ball Out Abrasive Waterjet Parts

Check Valve Assembly WS2003 Ball In Ball Out Abrasive Waterjet Parts

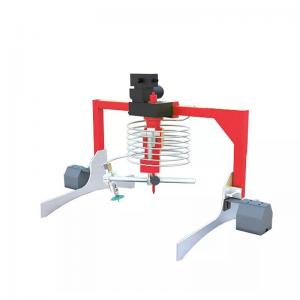

The Check Valve Assembly is a critical component in high-pressure waterjet cutting systems, designed to ensure smooth operation and superior performance. Built to withstand extreme pressures, this assembly guarantees effective flow control, helping maintain cutting precision and system reliability.

This Assembly Contains:

1-WA1011 Check Valve Body

1-WA1020 Check Valve Adapter

2-WA1023 O-Ring, Check Valve

1-WS1024 Outlet Seat

1-WA1029 Spring, Check Valve

1-WA1045 Retaining Screw, Check Valve, Hex Head

1-WS1019 Ball Guide

2-WS1022 Check Valve Ball

1-WS1023 Ball Retainer

INQUIRY